Sn-doped metastable gallium oxide crystal phase film and preparation method and application thereof

A gallium oxide and crystalline phase technology is applied in the field of metastable gallium oxide crystalline phase film and its preparation, which can solve the problems of thin metastable gallium oxide film, poor crystalline quality of gallium oxide, waste of film pollution and resources, etc. Consistent grain orientation, high crystallinity, and broadening the effect of the preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] One aspect of the embodiments of the present invention provides a method for preparing a Sn-doped metastable gallium oxide crystalline phase film, which includes:

[0033] Provide sapphire as substrate;

[0034] And, using pulsed laser deposition technology, using a Sn-doped gallium oxide ceramic target as a target, epitaxially growing a film on the surface of the substrate, and then annealing to obtain a Sn-doped metastable gallium oxide crystalline film;

[0035] Wherein, the molar percentage of Sn in the target is 0.1-5%;

[0036] The process conditions adopted by the pulse laser deposition technology include: the oxygen pressure is 0.1-200mT, the deposition temperature is 600-900°C, and the pulse laser energy density is 0.5-3J / cm 2 , the pulse laser frequency is 2-10 Hz, and the pulse deposition times are 3000-20000 times.

[0037] In some more specific embodiments, the preparation method includes:

[0038] Place the sapphire as the substrate in the pulsed laser ...

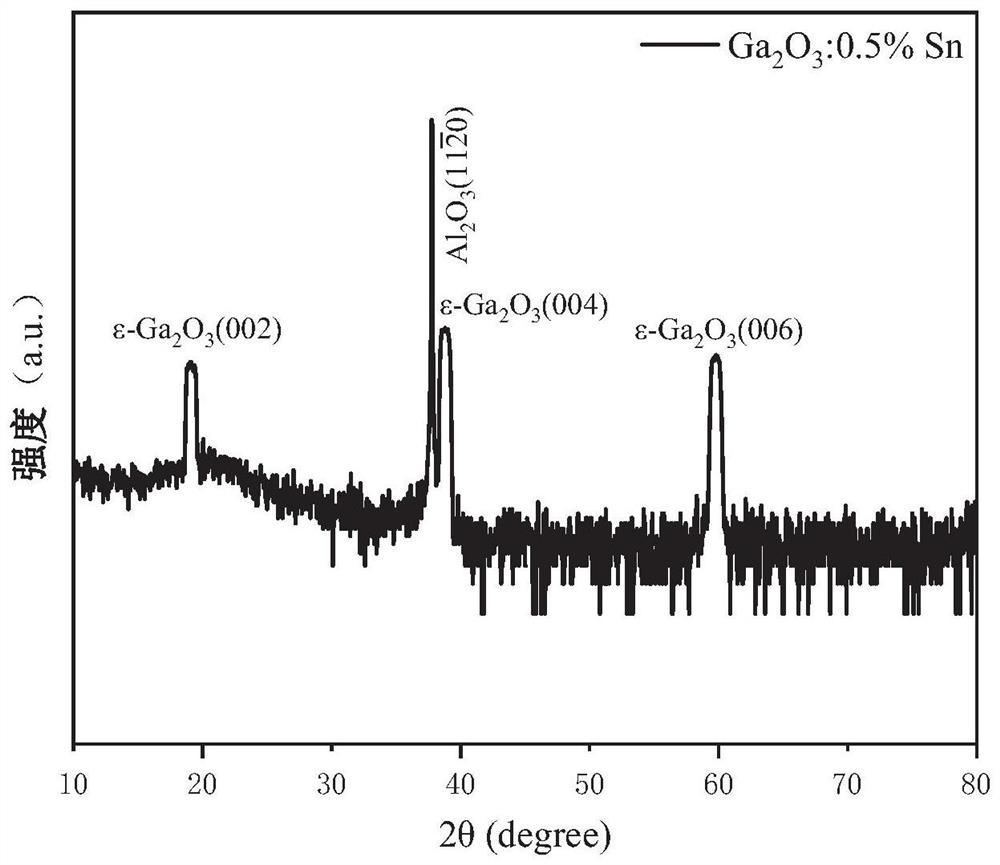

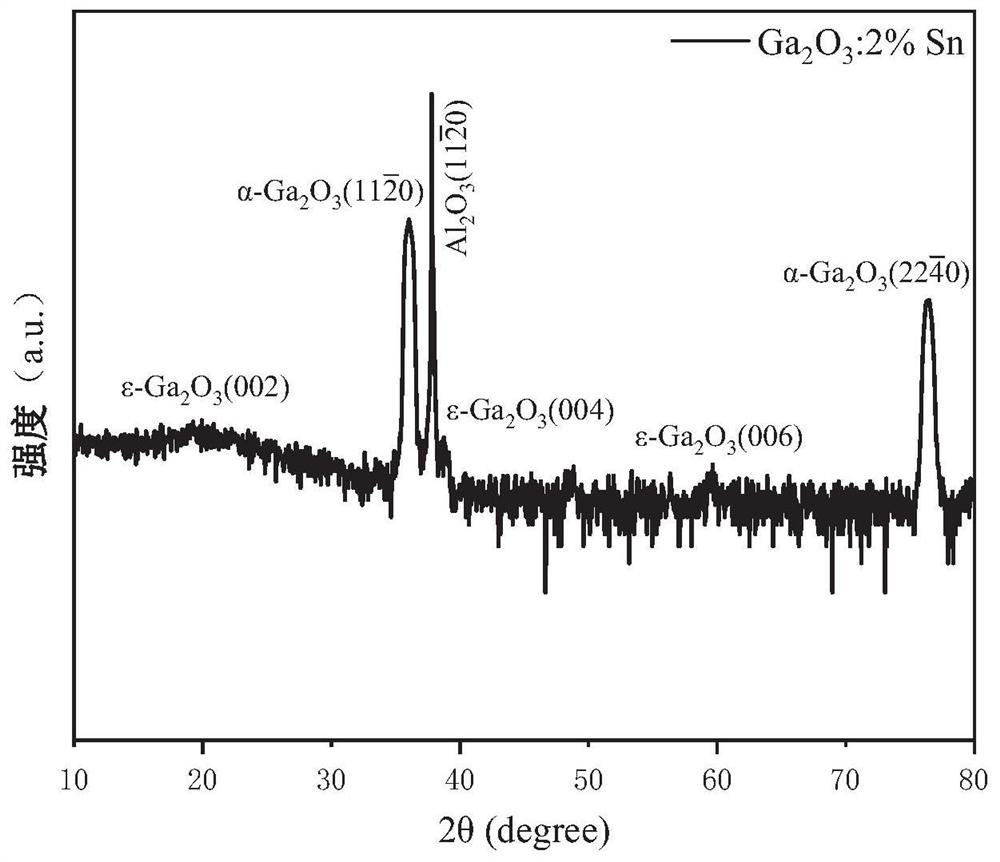

Embodiment 1

[0088] (1) Select the a-side (11-20) sapphire substrate, and dry it with high-purity nitrogen after cleaning;

[0089] (2) Place the substrate in a box furnace for pre-annealing. The pre-annealing temperature is 1000°C, the time is 2h, the atmosphere is air, and the heating rate and cooling rate are set at 10°C / min, so that the substrate is formed flat and uniform. the steps;

[0090] (3) A gallium oxide ceramic target with a Sn doping concentration of 0.5% mole fraction is used;

[0091] (4) Fix the pre-annealed substrate on the substrate holder, put it into the deposition chamber, adjust the distance between the target and the substrate to be 5cm, and evacuate to a vacuum degree of 10 -5 Below Pa;

[0092] (5) Heating the substrate to 800°C at a rate of 20°C / min and keeping it warm for 1800s;

[0093] (6) Adopt a pulsed laser deposition (PLD) system, feed high-purity oxygen, control the gas pressure to 20mT; set the pulsed laser energy density to 1J / cm 2 , the frequency ...

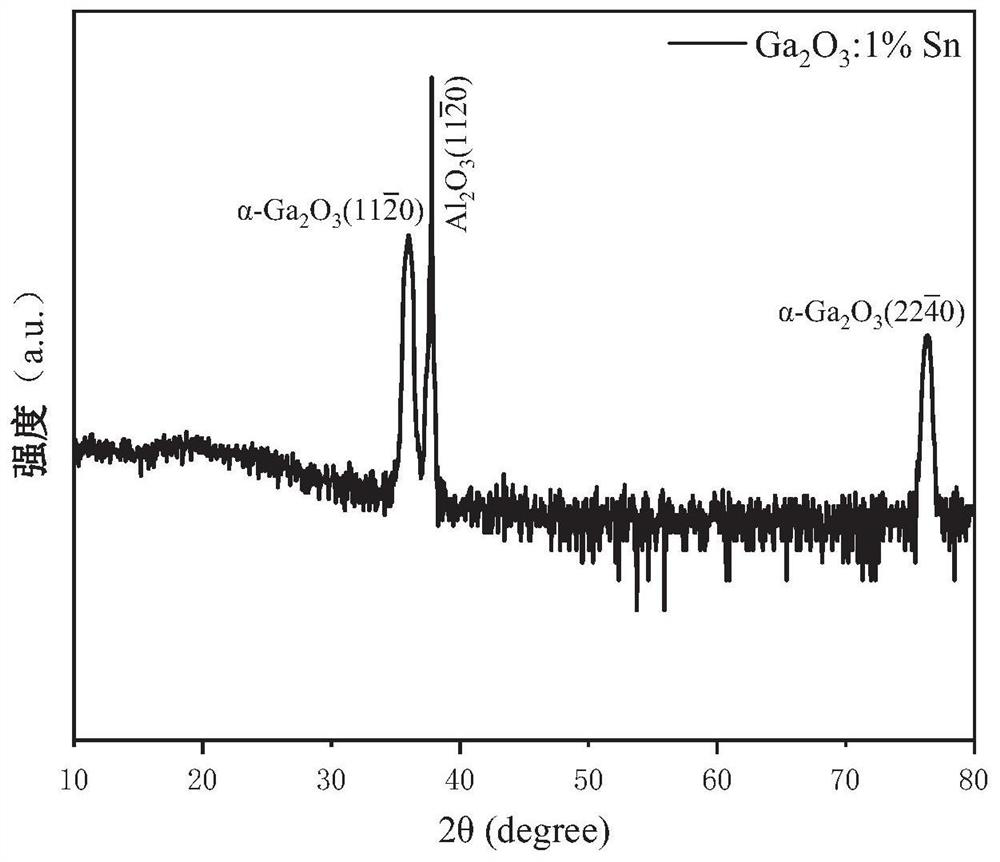

Embodiment 2

[0098] (1) Select the a-side (11-20) sapphire substrate, and dry it with high-purity nitrogen after cleaning;

[0099] (2) Place the substrate in a box furnace for pre-annealing, the pre-annealing temperature is 1000°C, the time is 2h, the atmosphere is air, the heating rate and cooling rate are set at 10°C / min, so that the substrate is formed flat uniform steps;

[0100] (3) A gallium oxide ceramic target with a Sn doping concentration of 1% mole fraction is used;

[0101] (4) Fix the pre-annealed substrate on the substrate holder, put it into the deposition chamber, adjust the distance between the target and the substrate to be 5cm, and evacuate to a vacuum degree of 10 -5 Below Pa;

[0102] (5) Heating the substrate to 800°C at a rate of 20°C / min and keeping it warm for 1800s;

[0103] (6) Adopt a pulsed laser deposition (PLD) system, feed high-purity oxygen, control the gas pressure to 20mT; set the pulsed laser energy density to 1J / cm 2 , the frequency is 5Hz, the pul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com