Coking wastewater reduction treatment method

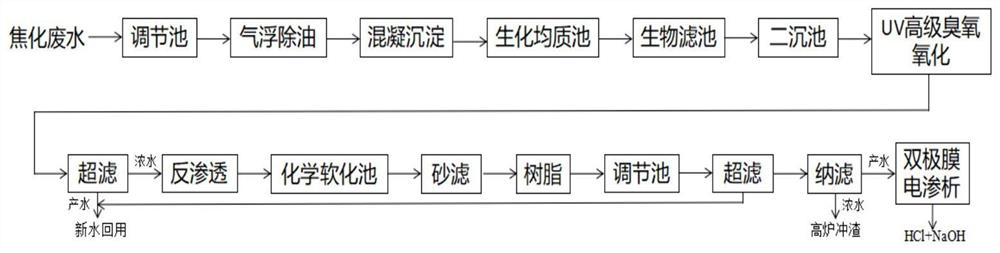

A technology of coking wastewater and treatment methods, which is applied in metallurgical wastewater treatment, oxidized water/sewage treatment, multi-stage water treatment, etc. It can solve the problems of direct discharge that cannot meet discharge standards, corrosion and scaling of equipment pipes and nozzles, and pollution of high-concentration salt water To avoid problems such as high concentration of pollutants, to achieve reduction and resource utilization, reduce outsourcing costs, and strengthen the effect of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method of treating a coking wastewater reduction, including the steps of:

[0029] 1 Znso 4 , Aeration time is 20 minutes, standing for 30 min.

[0030] 2, the supernatant enters the back-end high-efficiency shallow ionic air floating pool, putting the FESO of 40mg / L at the imported concrete 4 The auxiliary polyacrylamide (APAM) of the aiding agent, the residence time is provided to 10 min, and after thoroughly mixing, the scum is from the screw floating collecting device to the slag cell, and the water entering the secondary sedimentation area, using The tubular precipitation method is divided into a series of shallowly precipitated layers by tilted parallel tubes, and the precipitate moves and separated in the respective deposition shallow layers to achieve the purpose of precipitation.

[0031] 3, the precipitation of 40 min after gravity effluent into the biochemical homogeneous tank, the wastewater after the homogeneous metric is increased into the V-type biofine f...

Embodiment 2

[0040] A method of treating a coking wastewater reduction, including the steps of:

[0041] 1 Znso 4 The aeration time is 25 minutes, and stands for 35min.

[0042] 2, the supernatant enters the bacterial high-efficiency shallow ionic air floating pool at the rear end, and the FESO of the coagulator 45mg / L is put. 4 The anionic polyacrylamide (APAM) of the condalent agent 15mg / L, the residence time is provided to 13 min, and after sufficiently mixing, the scum is from the screw floating collecting device to the slag cell, and the water entering the end of the precipitation area, using The tubular precipitation method is divided into a series of shallowly precipitated layers by tilted parallel tubes, and the precipitate moves and separated in the respective deposition shallow layers to achieve the purpose of precipitation.

[0043] 3, the clear water gravity after 45 min effluent into the biochemical homogeneous tank, the wastewater after homogeneous metric passes through the p...

Embodiment 3

[0052] A method of treating a coking wastewater reduction, including the steps of:

[0053] 1 Znso 4 , Aeration time is 30 minutes, standing for 40 min.

[0054] 2, the supernatant enters the bacterial high-efficiency shallow ionic air floating pool at the rear end, and the FESo of the coagulant 50mg / L is added at the import. 4 , The anionic polyacrylamide (APAM) of the aiding agent, the residence time is provided to 15 minutes, and after sufficiently mixing flocculation, the scum is brought into the slag cell through the spiral scum collection device, and the water entering the secondary sedimentation area, using The tubular precipitation method is divided into a series of shallowly precipitated layers by tilted parallel tubes, and the precipitate moves and separated in the respective deposition shallow layers to achieve the purpose of precipitation.

[0055] 3. The precipitation of 50 min after gravity effluent into the biochemical homogeneous pool, the wastewater after homoge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com