NiCo spinel catalyst material with nano structure as well as preparation method and application of NiCo spinel catalyst material

A nanostructure and spinel technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of catalytic cracking of lignin with long reaction time and non-precious metal Low catalyst efficiency, cumbersome synthesis steps, etc., to achieve the effect of compact structure, multiple active sites, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Weigh 0.2910g Ni(NO 3 ) 3 ·6H 2 O, 0.5820g Co(NO 3 ) 3 ·6H 2 O, 0.4920 g anhydrous CH 3 Dissolve COONa in 30mL ethylene glycol, stir vigorously for 30min, transfer the solution to a 50ml polytetrafluoroethylene reactor, put it in an oven and heat it for 16h at 200°C;

[0031] (2) Take out the reacted product, filter out the precipitate, wash with deionized water and absolute ethanol respectively, and centrifuge 5 times to obtain the precipitate; heat the precipitate in an oven for 12 hours at 80°C, and collect to obtain a purple color product;

[0032] (3) Put the purple product into a muffle furnace for calcination, the calcination time is 2h, the calcination temperature is 350°C, and the heating rate during the calcination process is 1°C / min; after the temperature is cooled to room temperature, the product is collected to obtain the present invention Nanostructured NiCo spinel catalyst material.

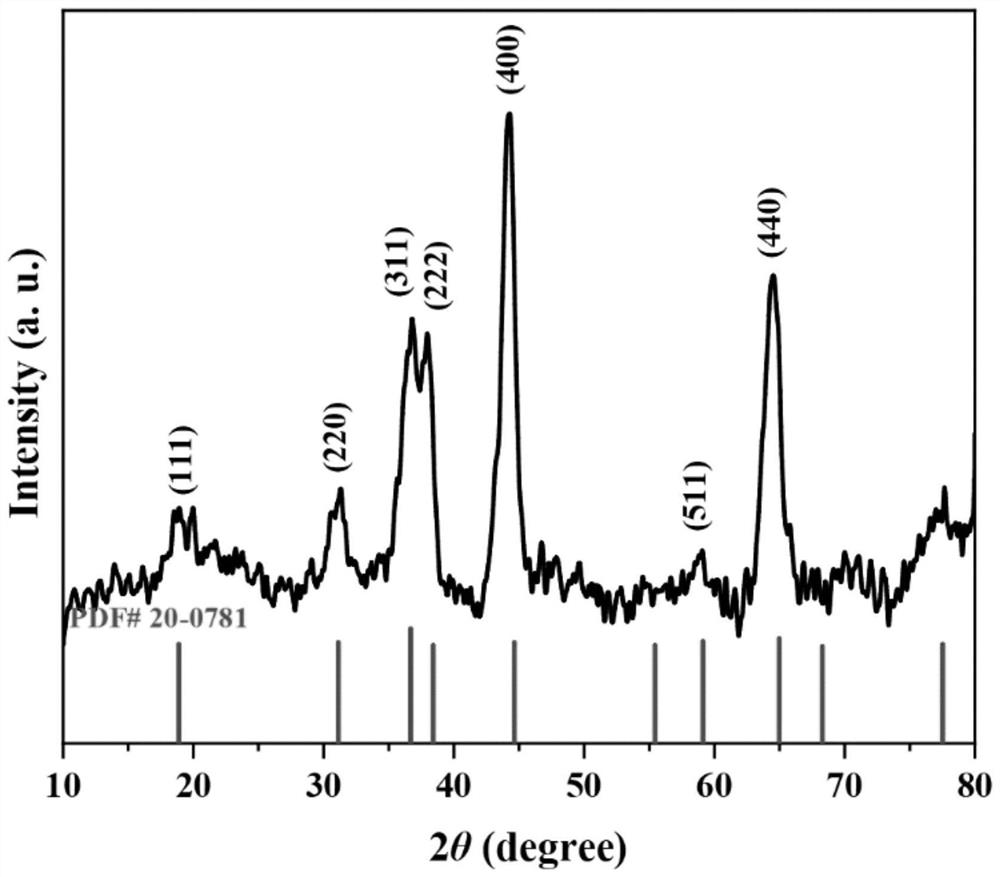

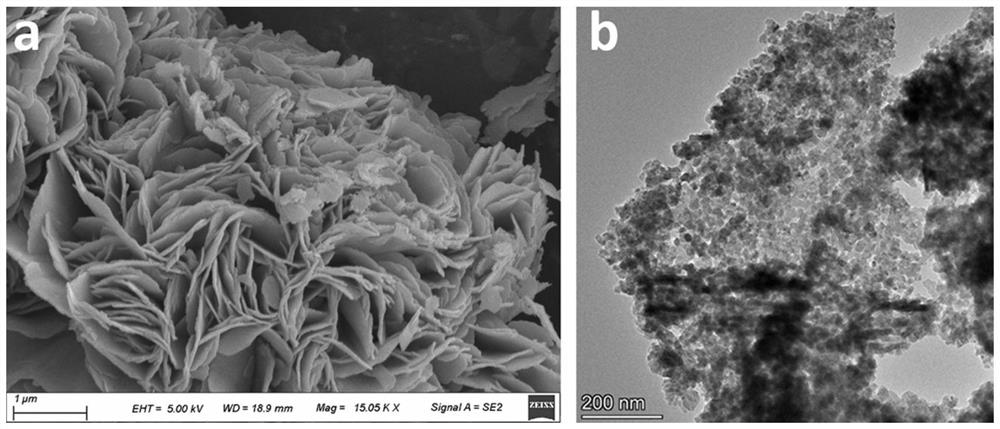

[0033] see figure 1, the X-ray powder diffraction analysis...

Embodiment 2

[0036] (1) Weigh 0.0291g Ni(NO 3 ) 2 ·6H 2 O, 0.8439g Co(NO 3 ) 2 ·6H 2 O, 0.492 g anhydrous CH 3 Dissolve COONa in 30mL ethylene glycol, stir vigorously for 30min, transfer the solution to a 50ml polytetrafluoroethylene reactor, put it in an oven and heat it for 16h at 200°C;

[0037] (2) Take out the reacted product, filter out the precipitate, wash with deionized water and absolute ethanol respectively, and centrifuge 5 times to obtain the precipitate; heat the precipitate in an oven for 12 hours at 80°C, and collect to obtain a purple color product;

[0038] (3) Put the purple product into a muffle furnace for calcination, the calcination time is 2h, the calcination temperature is 350°C, and the heating rate during the calcination process is 1°C / min; after the temperature is cooled to room temperature, the product is collected to obtain the present invention Nanostructured NiCo spinel catalyst material.

[0039] The nanostructured NiCo spinel catalyst material prep...

Embodiment 3

[0041] (1) Weigh 0.0582g Ni(NO 3 ) 3 ·6H 2 O, 0.8148g Co(NO 3 ) 3 ·6H 2 O, 0.492 g anhydrous CH 3 Dissolve COONa in 30mL ethylene glycol, stir vigorously for 30min, transfer the solution to a 50ml polytetrafluoroethylene reactor, put it in an oven and heat it for 16h at 200°C;

[0042] (2) Take out the reacted product, filter out the precipitate, wash with deionized water and absolute ethanol respectively, and centrifuge 5 times to obtain the precipitate; heat the precipitate in an oven for 12 hours at 80°C, and collect to obtain a purple color product;

[0043] (3) Put the purple product into a muffle furnace for calcination, the calcination time is 2h, the calcination temperature is 350°C, and the heating rate during the calcination process is 1°C / min; after the temperature is cooled to room temperature, the product is collected to obtain the present invention Nanostructured NiCo spinel catalyst material.

[0044] The nanostructured NiCo spinel catalyst material prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com