Method for preparing biodiesel from tea oil cakes

A technology for biodiesel and tea oil cake, which is applied in the fields of biofuels, separation methods, fat oil/fat refining, etc., can solve the problems of reducing the efficiency and yield of biodiesel preparation, increasing the viscosity of the reaction system, reducing the catalytic effect, etc., so as to improve the utilization rate. Value, reduce usage, improve catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

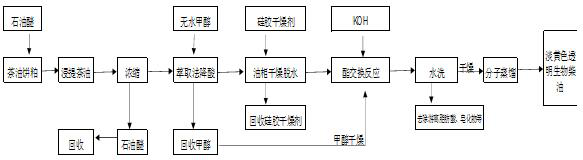

[0041] A method for preparing biodiesel from tea oil cake, comprising the following steps:

[0042] 1) Oil extraction: a) Use a high-speed pulverizer to pulverize the tea oil cake into small particles and pass through a 60-mesh sieve; after sieving, dry it at a temperature of 75°C until it reaches a constant weight for use; b) Use a Soxhlet pump The extraction method is to extract the camellia oil in the tea seed cake with petroleum ether, the extraction conditions are: the temperature is 70°C, the extraction time is 8h, after the extraction is completed, the tea oil is collected and set aside;

[0043] 2) Concentration: the obtained camellia oil is concentrated using a rotary evaporator, and after the petroleum ether is completely separated, the crude camellia oil is collected for use;

[0044] 3) Extraction method for acid reduction: put the obtained camellia oil into a conical flask, at room temperature, add anhydrous methanol for extraction according to the solvent volume / te...

Embodiment 2

[0054] A method for preparing biodiesel from tea oil cake, comprising the following steps:

[0055] 1) Oil extraction: a) Use a high-speed pulverizer to pulverize the tea oil cake into small particles and pass through a 60-mesh sieve; after sieving, dry it at a temperature of 75°C until it reaches a constant weight for use; b) Use a Soxhlet pump The extraction method is to extract the camellia oil in the tea seed cake with petroleum ether, the extraction conditions are: the temperature is 70°C, the extraction time is 8h, after the extraction is completed, the tea oil is collected and set aside;

[0056] 2) Concentration: the obtained camellia oil is concentrated using a rotary evaporator, and after the petroleum ether is completely separated, the crude camellia oil is collected for use;

[0057] 3) Extraction method for acid reduction: put the obtained camellia oil into a conical flask, at room temperature, add anhydrous methanol for extraction according to the solvent volume / ...

experiment example 1

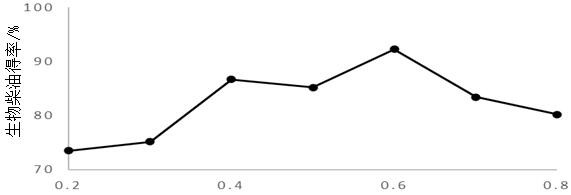

[0063] Experimental example 1 Optimization experiment of KOH catalyst dosage

[0064] This experimental example 1 adopts the method for preparing biodiesel in Example 1. In step 5) transesterification reaction, the reaction temperature is 70°C, the reaction time is 90min, and the mass ratio of dried anhydrous methanol to deacidified tea oil is Under the condition of 6:1, KOH was used as the catalyst to study the effect of different KOH catalyst additions on the yield of biodiesel. The experimental results are as follows: figure 2 shown.

[0065] from figure 2 The results showed that: when the KOH concentration was 0.2%-0.6%, the yield of biodiesel showed an upward trend, and after the concentration of 0.6%, the yield of biodiesel showed a downward trend. It can be seen that in the process of transesterification, KOH firstly reacts with free fatty acids, resulting in partial inactivity of the catalytic reaction, resulting in a low yield of biodiesel; with the increase of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com