Epoxy resin composite material and preparation method thereof

A technology of epoxy resin and composite materials, which is applied in the field of advanced composite materials, can solve the problems of poor wettability, high brittleness, and poor toughness of composite materials, and achieve the effects of high interface bonding strength, improved surface state, and enhanced interface strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of epoxy resin composite material, comprise the epoxy resin matrix and carbon fiber that weight ratio is 2:3, wherein, described epoxy resin matrix comprises the raw material of following weight portion:

[0037] 100 parts of organosilicon-modified cardanol-based epoxy resins, 40 parts of lignin-based epoxy resins, 5 parts of interface modifiers, 30 parts of reactive diluents, 15 parts of curing agents, and 40 parts of solvents;

[0038]The interface modifier is a polymer particle with a core-shell structure, the shell layer has an amino group, and the particle size is 150nm; the reactive diluent is ethylene glycol diglycidyl ether and butyl glycidyl ether according to the weight ratio 1:1 mixture; the curing agent is a mixture of polyetheramine and 2-methylimidazole according to a weight ratio of 1:2; the solvent is isopropanol;

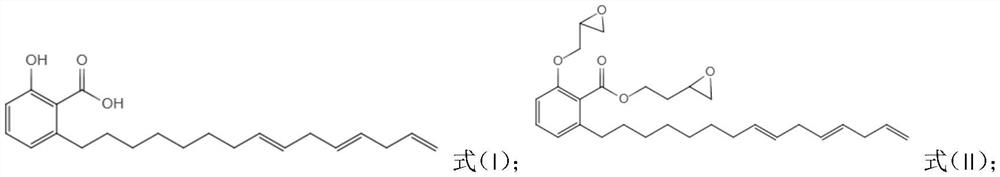

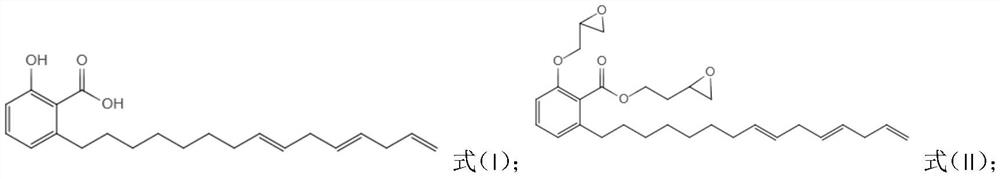

[0039] The epoxy equivalent of the organosilicon-modified cardanol-based epoxy resin is 300g / eq, which is prepared by the following p...

Embodiment 2

[0050] A kind of epoxy resin composite material, comprise the epoxy resin matrix and carbon fiber that weight ratio is 2:2, wherein, described epoxy resin matrix comprises the raw material of following weight portion:

[0051] 50 parts of organosilicon-modified cardanol-based epoxy resins, 50 parts of lignin-based epoxy resins, 5 parts of interface modifiers, 30 parts of reactive diluents, 10 parts of curing agents, and 60 parts of solvents;

[0052] The interface modifier is a polymer particle with a core-shell structure, the particle size is 300nm, and the shell layer of the interface modifier has a carboxyl group, which is used to crosslink the epoxy group in the epoxy resin reaction.

[0053] The reactive diluent is a mixture of propylene glycol diglycidyl ether and benzyl glycidyl ether in a weight ratio of 2:1; the curing agent is isophorone diamine and 1,2-dimethylimidazole in a weight ratio 1:1 mixture; The solvent is diethylene glycol methyl ether;

[0054] The epox...

Embodiment 3

[0069] A kind of epoxy resin composite material, comprise the epoxy resin matrix and carbon fiber that weight ratio is 3:2, wherein, described epoxy resin matrix comprises the raw material of following weight portion:

[0070] 80 parts of organosilicon-modified cardanol-based epoxy resins, 30 parts of lignin-based epoxy resins, 2 parts of interface modifiers, 25 parts of reactive diluents, 14 parts of curing agents, and 50 parts of solvents;

[0071] The interface modifier is a polymer particle with a core-shell structure, the particle size is 200nm, and the shell layer of the interface modifier has amino groups, which are used for crosslinking the epoxy groups in the epoxy resin reaction.

[0072] The reactive diluent is a mixture of propylene glycol diglycidyl ether and C8 alkyl glycidyl ether in a weight ratio of 2:3; the curing agent is octyldiamine and 1,2-dimethylimidazole in a weight ratio of 1:1 The mixture; The solvent is ethylene glycol methyl ether acetate;

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com