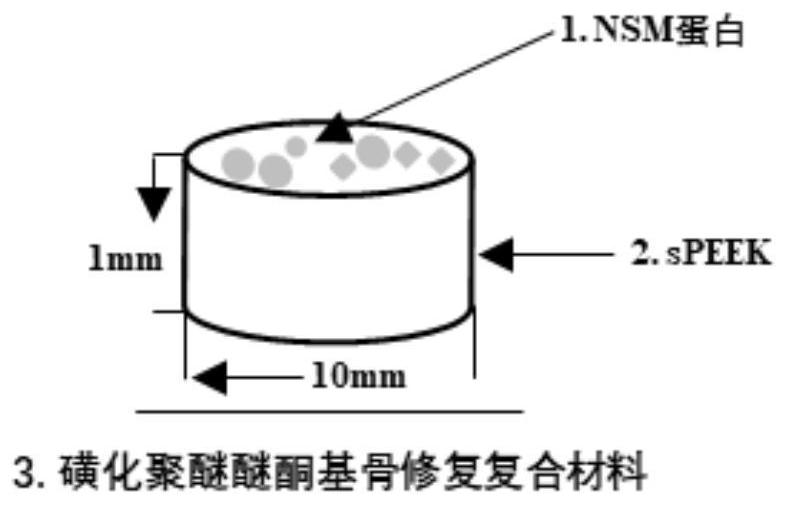

A sulfonated polyetheretherketone-based bone repair composite material

A technology of sulfonated polyether ether ketone and composite materials, which is applied in organic chemistry, chemical instruments and methods, carrier binding/immobilizing peptides, etc., can solve the problems of single physiological function of the body and the inability to achieve the unity of multiple properties, and achieve Good biocompatibility, promotion of bone marrow mesenchymal stem cell adhesion, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

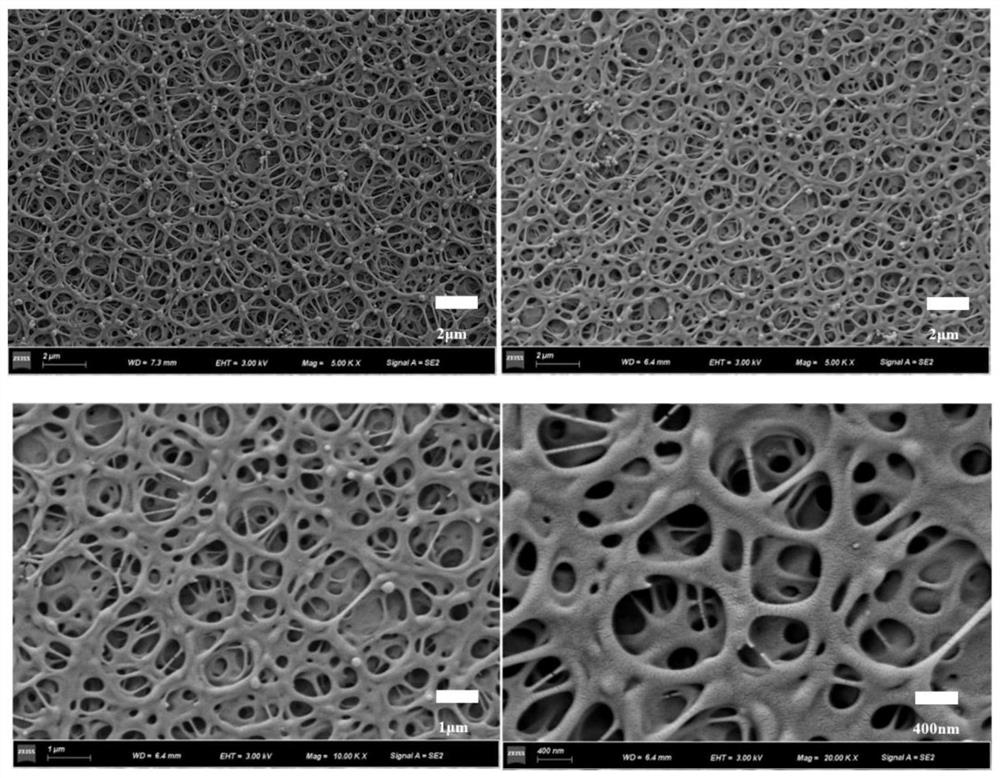

[0049] (1) Polish one side of a cylindrical polyetheretherketone (PEEK) with a diameter of 10mm and a thickness of 1mm to mirror smoothness, ultrasonically clean it with acetone, absolute ethanol and deionized water for 3 times for 15 minutes each time, and then at room temperature Dry for 24 hours to obtain a spare polyetheretherketone (PEEK); in a ventilated table, the polyetheretherketone (PEEK) was subjected to 18.4mol / L concentrated sulfuric acid rotary sulfonation for 40s, and then washed with ultrapure water to remove residual concentrated sulfuric acid and water. Thermal treatment to remove sulfur (hydrothermal conditions: 120°C, 4h), in N 2 The sulfonated polyether ether ketone (S-PEEK) was obtained after drying in airflow for 24 h.

[0050] (2) Weigh 33.62g EDTANa 2 (Ethylenediaminetetraacetic acid disodium salt), dissolve in 2000ml ultrapure water, stir to make 0.05M / L EDTANa 2 solution, add NaOH solid particles while stirring, after the solution is clarified, sto...

Embodiment 2

[0073] Same as Example 1, the difference is that the preparation process of step (1) sulfonated polyether ether ketone is omitted.

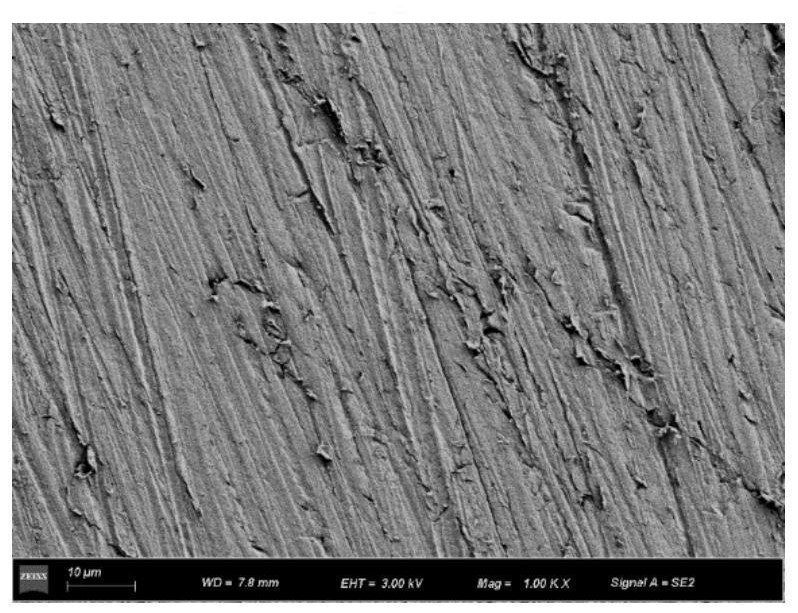

[0074] The results show that there is no 3D network structure on the surface of the material. Although the surface structure is polished by sandpaper, the surface is still rough and there are many scratches on the surface. It is generally believed that the 3D network structure is beneficial to the adhesion of cells due to its increased surface roughness and enhanced hydrophilicity. Sulfonated polyetheretherketone materials of nanoproteins.

Embodiment 3

[0076] Same as Example 1, the difference is that the hydrothermal treatment step in the preparation process of step (1) sulfonated polyether ether ketone is omitted.

[0077] The results showed that most of the SD rat bone marrow mesenchymal stem cells died without the ability of attachment, proliferation and differentiation.

[0078] The purpose of the hydrothermal treatment step is two: first: remove the residual concentrated sulfuric acid (because the presence of residual concentrated sulfuric acid is not conducive to cell attachment, proliferation and differentiation); second: the hydrothermal treatment can stabilize the sulfonated polyether ether The 3D network structure on the surface of the ketone can reduce the unfavorable effects on cell attachment, proliferation and differentiation caused by the instability of the 3D network structure in the later experiments.

[0079] If there is no hydrothermal treatment step, the residual sulfuric acid of the sulfonated polyethere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com