A class of organic electrogenerated standard saturated red-light-emitting materials, preparation method and OLED application thereof

An electromechanical and standard technology, applied in luminescent materials, chemical instruments and methods, organic chemistry, etc., can solve the problems of lack of high-efficiency red-light AIE materials, and achieve high yield, stable structure, and simple synthesis methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Preparation of saturated red material (TNZTPE).

[0051]

[0052] The synthetic route is as follows:

[0053]

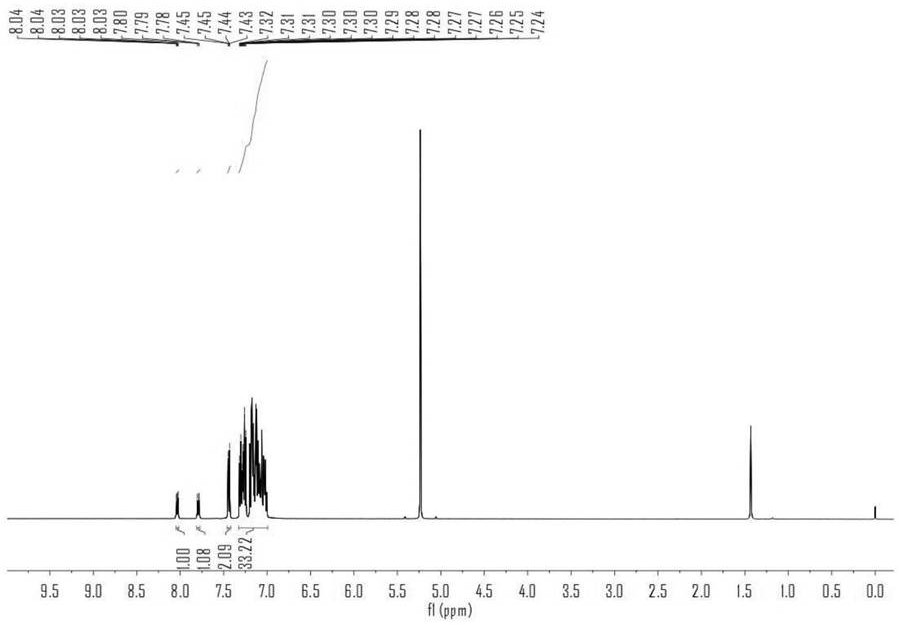

[0054](1) Under nitrogen atmosphere, tetrakis (triphenylphosphine) palladium (57.75mg, 0.05mmol), 4-triphenylamine borate (1.45g, 5mmol) and 4,9-dibromonaphthothiadiazole (1.7 g, 5mmol) was dissolved in 60mL of toluene solution, mixed uniformly and heated to 90°C. Potassium carbonate aqueous solution (2.4M, 24mL) was injected into the above solution and heated to 110°C, and reacted at this temperature for 24h. Cool down to room temperature, extract with dichloromethane and water three times, dry over anhydrous magnesium sulfate for 2 h, concentrate, stir evenly with silica gel powder and pass through the column to obtain purple black powder (1.27 g), yield 51%.

[0055] In the case of the same reaction raw material ratio, the heating reaction temperature is set to 90°C, the reaction time is 24h, the reaction solvent is toluene, and the reaction lye is ...

Embodiment 2

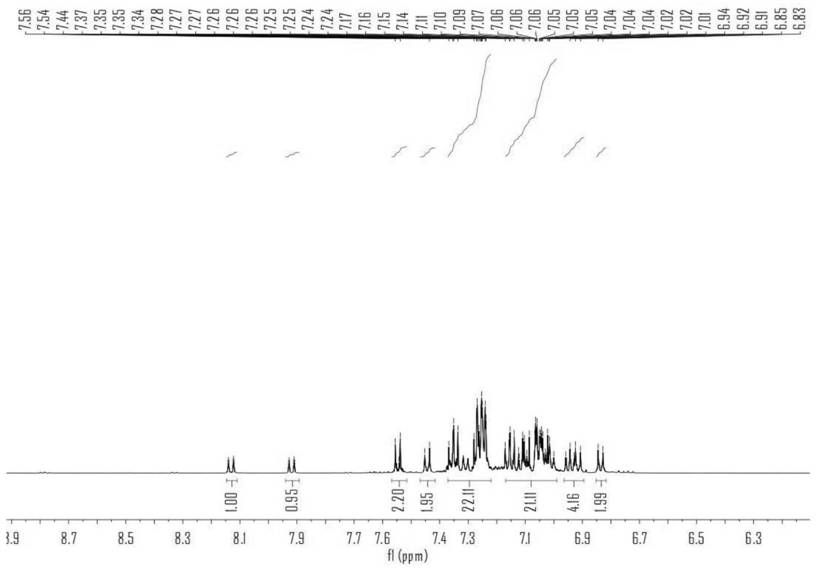

[0071] Preparation of saturated red light material (TNZTPETPA).

[0072]

[0073] The synthetic route is as follows:

[0074]

[0075] (1) Under nitrogen atmosphere, tetrakis(triphenylphosphine)palladium (57.75mg, 0.05mmol), raw material 2 (1.69g, 3.33mmol) and raw material 3 (3.51g, 5mmol) were dissolved in 60mL of toluene solution , mix well and heat up to 90°C. Potassium carbonate aqueous solution (2.4M, 24mL) was injected into the above solution and heated to 110°C, and reacted at this temperature for 24h. Cool down to room temperature, extract with dichloromethane and water three times, dry over anhydrous magnesium sulfate for 2 hours, concentrate, stir evenly with silica gel powder and pass through the column to obtain a red powder (2.02g), with a yield of 74%.

[0076] In the case of the same reaction raw material ratio, the heating reaction temperature was set to 90°C, the reaction time was 24h, the reaction solvent was toluene, and the reaction lye was potassi...

Embodiment 3

[0084] Research on performance optimization of OLEDs based on saturated red material (TNZTPE).

[0085] Utilize the TNZTPE (solid-state fluorescence quantum efficiency=50%) prepared in Example 1 to prepare non-doped devices as luminescent materials, and test and characterize its device performance, the results are shown in Figure 1~3 .

[0086] Non-doped device structure: ITO / HATCN(5nm) / TAPC(60nm) / TNZTPE(20nm) / TmPyPB(50nm) / LiF(1nm) / Al(120nm);

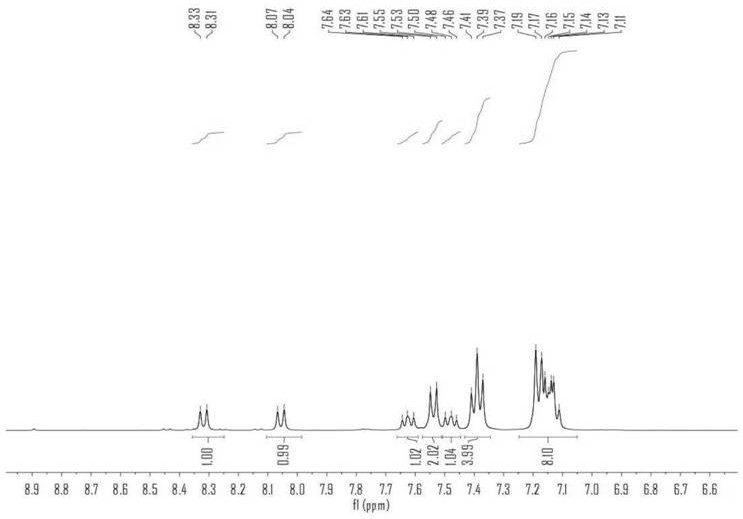

[0087] figure 1 It is based on the electroluminescence spectrum of the OLEDs device obtained in Example 1. It can be seen from the figure that the maximum electroluminescence wavelength is located at 658nm. figure 2 It is based on the J-V-L curve diagram of the OLEDs device obtained in Example 1, as can be seen from the figure, the device turn-on voltage is 3.3V and the maximum brightness is 1469cd / m 2 . image 3 It is a graph based on the efficiency of the obtained OLEDs device of embodiment 1 with brightness variation, as can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com