Flocculating agent for oil-based drilling fluid and preparation method of flocculating agent

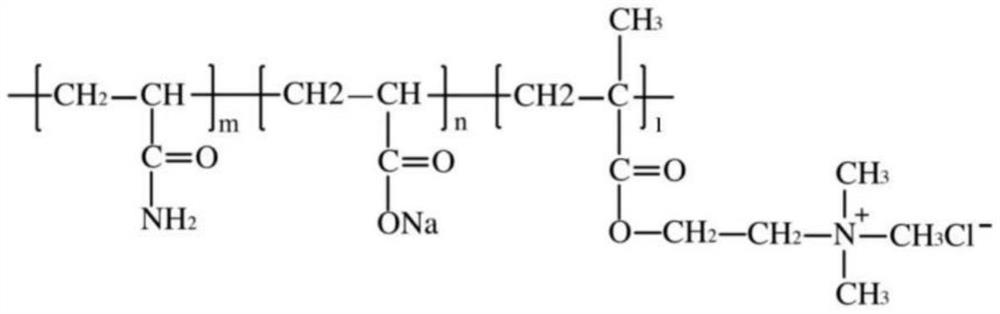

An oil-based drilling fluid and flocculant technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of limited equipment design and production, and achieve the effect of reducing viscosity and strong netting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

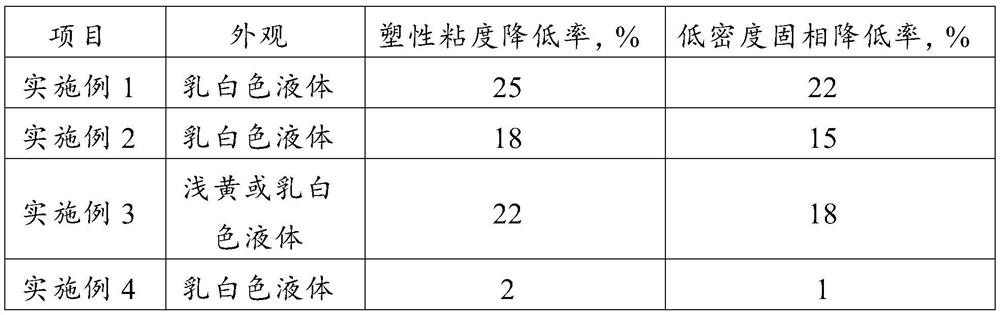

Examples

Embodiment 1

[0033] This embodiment provides a flocculant for oil-based drilling fluid. The raw materials for its preparation include: 60 kg of acrylamide aqueous solution (98%, Sinopharm Chemical Reagent Co., Ltd.), quaternary ammonium salt cationic monomer (diallyl dimethyl Ammonium chloride (DMDAAC, Shandong Kepler) 15kg, sodium acrylate (99.9%, Shandong Kepler) 5kg, sodium ethylenediaminetetraacetate (EDTA-2Na, Sinopharm Chemical Reagent Co., Ltd.) 0.5kg, urea (Sinopharm Group Chemical Reagent Co., Ltd.) 0.1kg, surfactant 1 (Span-80, Hebei Runbu) 10kg, surfactant 2 (OP-10, Jinan Huijinchuan Chemical Industry) 2kg, initiator (azobis Isobutyronitrile, Sinopharm Chemical Reagent Co., Ltd.) 0.05kg, solvent (5# white oil, Maoming Petrochemical) 40kg.

[0034] Mix 60 kg of acrylamide aqueous solution and 15 kg of quaternary ammonium cationic monomers evenly, add 5 kg of sodium acrylate, 0.5 kg of sodium ethylenediamine tetraacetate and 0.1 kg of urea under cooling conditions, and keep stirri...

Embodiment 2

[0036]This example provides a flocculant for oil-based drilling fluid, the raw materials for its preparation include: 55 kg of acrylamide aqueous solution (98%, Sinopharm Chemical Reagent Co., Ltd.), quaternary ammonium salt cationic monomer (acryloyloxyethyl tris Methylammonium chloride (DAC, Kepler, Shandong) 15kg, sodium acrylate (99.9%, Kepler, Shandong) 5kg, sodium ethylenediaminetetraacetate (EDTA-2Na, Sinopharm Chemical Reagent Co., Ltd.) 0.3kg, Urea (Sinopharm Chemical Reagent Co., Ltd.) 0.1kg, surfactant 1 (Span-80, Hebei Runbu) 10kg, surfactant 2 (sodium α-olefin sulfonate (AOS), BOSF) 5kg, initiator 1 (potassium persulfate, Sinopharm Chemical Reagent Co., Ltd.) 0.06kg, initiator 2 (sodium bisulfite, Sinopharm Chemical Reagent Co., Ltd.) 0.04kg, solvent (5# white oil, Maoming Petrochemical) 50kg.

[0037] Mix 55 kg of acrylamide aqueous solution and 15 kg of quaternary ammonium cationic monomers evenly, add 5 kg of sodium acrylate, 0.3 kg of sodium edetate and 0.1 kg...

Embodiment 3

[0039] This embodiment provides a flocculant for oil-based drilling fluid, and the raw materials for its preparation include: 60 kg of acrylamide aqueous solution (98%, Sinopharm Chemical Reagent Co., Ltd.), quaternary ammonium salt cationic monomer (N,N-dimethyl Base-N-benzyl-N-acrylamido ammonium chloride (DBAAC), Jinan Huijinchuan Chemical) 10kg, sodium acrylate (99.9%, Shandong Kepler) 2kg, sodium ethylenediaminetetraacetate (EDTA-2Na , Sinopharm Chemical Reagent Co., Ltd.) 0.5kg, urea (Sinopharm Chemical Reagent Co., Ltd.) 0.1kg, surfactant 1 (Span-80, Hebei Runbu) 12kg, surfactant 2 (hexadecyltrimethyl ammonium chloride, Sinopharm Chemical Reagent Co., Ltd.) 3kg, initiator (azobisisobutyronitrile, Sinopharm Chemical Reagent Co., Ltd.) 0.05kg, solvent (5# white oil, Maoming Petrochemical) 60kg.

[0040] Mix 60 kg of acrylamide aqueous solution and 10 kg of quaternary ammonium cationic monomers evenly, add 2 kg of sodium acrylate, 0.5 kg of sodium ethylenediamine tetraacet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com