High-density and high-yield porphyridium culture method

A technology of high-density culture and culture method, which is applied in the field of high-density and high-yield Porphyridium algae culture, can solve the problems of inability to recycle the culture medium, restrict the development of industrialization, and difficult to recycle the medium, and achieve high cell density and Product yield, addressing nutrient limitation issues, mitigation of inhibitory and toxic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

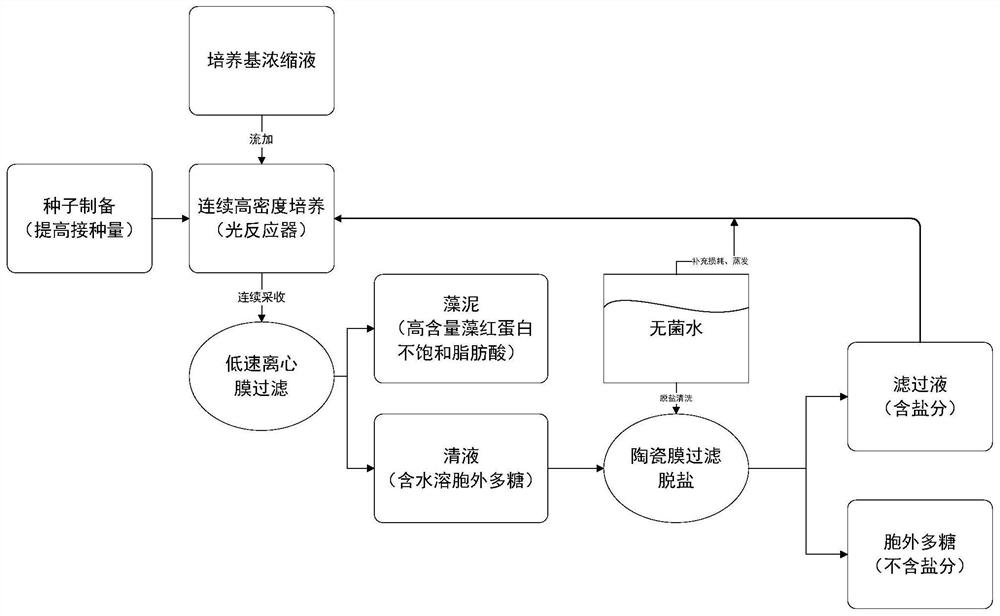

Method used

Image

Examples

Embodiment 1

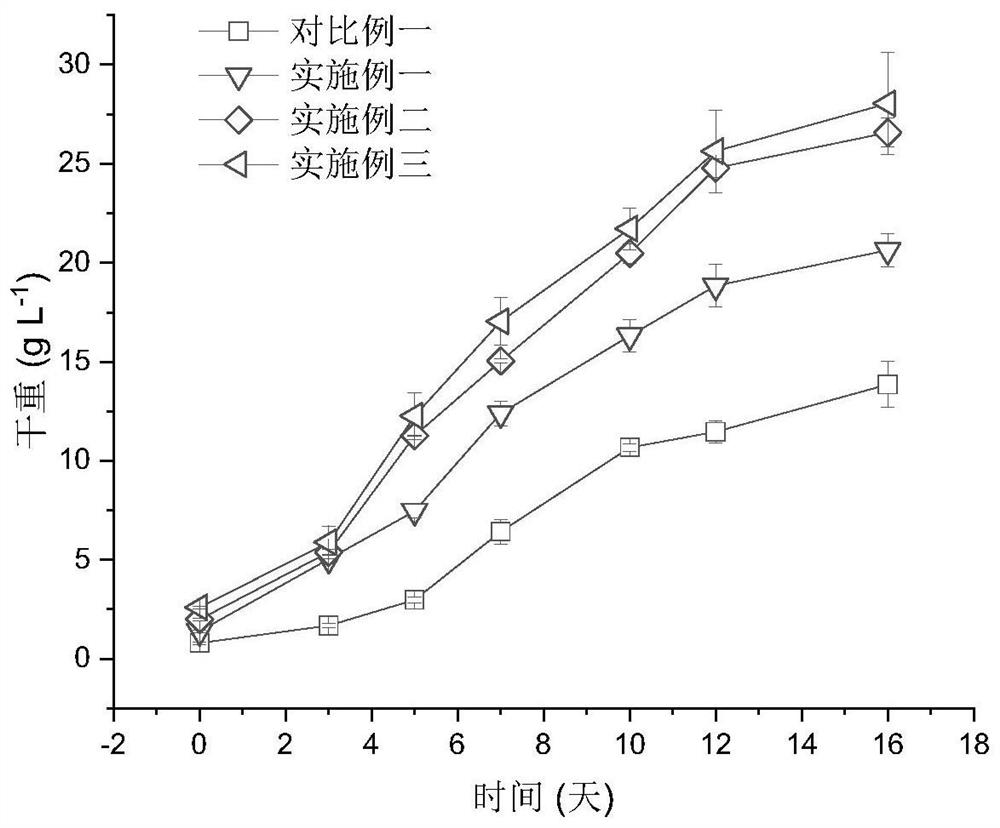

[0090] Embodiment one (improve inoculation density)

[0091] The comparative experiment was carried out in the same 1L glass bubbling column reactor as the comparative example. Light irradiation on both sides, the light intensity on the surface of the reactor is 400μE m -2 the s -1 . Aeration was carried out by bubbling through a stainless steel tube with a diameter of 2 mm extending into the bottom of the reactor.

[0092] The marine microalga Porphyridium cruentum is cultivated in the reactor, and the culture medium is ASW medium with potassium nitrate as the nitrogen source. The filling volume is 700mL, and the inoculation density is increased to 1.4g L -1 . CO 2 The volume fraction is 5% air carbon dioxide mixture, the ventilation volume is 0.14L min -1 , control the culture temperature at 25±1°C. The content of potassium nitrate and potassium dihydrogen phosphate is monitored during the process. When the content drops to 1 / 2 of the initial value, the above-mention...

Embodiment 2

[0093] Embodiment two (improve inoculation density 2)

[0094] The comparative experiment was carried out in the same 1L glass bubbling column reactor as the comparative example. Light irradiation on both sides, the light intensity on the surface of the reactor is 400μE m -2 the s -1 . Aeration was carried out by bubbling through a stainless steel tube with a diameter of 2 mm extending into the bottom of the reactor.

[0095] The marine microalga Porphyridium cruentum is cultivated in the reactor, and the culture medium is ASW medium with potassium nitrate as the nitrogen source. The filling volume is 700mL, and the inoculation density is 2g L -1 . CO 2 The volume fraction is 5% air carbon dioxide mixture, the ventilation volume is 0.14L min -1 , control the culture temperature at 25±1°C. The content of potassium nitrate and potassium dihydrogen phosphate is monitored during the process. When the content drops to 1 / 2 of the initial value, the above-mentioned nutrient c...

Embodiment 3

[0096] Embodiment three (improve inoculation density)

[0097] The comparative experiment was carried out in the same 1L glass bubbling column reactor as the comparative example. Light irradiation on both sides, the light intensity on the surface of the reactor is 400μE m -2 the s -1 . Aeration was carried out by bubbling through a stainless steel tube with a diameter of 2 mm extending into the bottom of the reactor.

[0098] The marine microalga Porphyridium cruentum is cultivated in the reactor, and the culture medium is ASW medium with potassium nitrate as the nitrogen source. The filling volume is 700mL, and the inoculation density is 2.6g L -1 . CO 2 The volume fraction is 5% air carbon dioxide mixture, the ventilation volume is 0.14L min -1 , control the culture temperature at 25±1°C. The content of potassium nitrate and potassium dihydrogen phosphate is monitored during the process. When the content drops to 1 / 2 of the initial value, the above-mentioned nutrient...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volumetric yield | aaaaa | aaaaa |

| Volumetric yield | aaaaa | aaaaa |

| Volumetric yield | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com