Ultrahigh molecular weight polyethylene reinforced polypropylene composite material and preparation method thereof

A technology of ultra-high molecular weight and composite materials, which is applied in the field of ultra-high molecular weight polyethylene reinforced polypropylene composite materials and its preparation, can solve the problems of unfavorable transportation and handling of large-scale radome systems, large dielectric constant, and large signal loss, etc., to achieve Improve the interface bonding fastness, improve the degree of fusion, improve the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Dissolve 3 parts of silane coupling agent in 97 parts of organic solvent aqueous solution (the organic solvent aqueous solution is obtained by blending distilled water and methanol at a volume ratio of 1:1) to obtain a mixed solution; add 2 parts of porous nano-silica Stir evenly in 98 parts of the mixed solution to obtain a dispersion with a concentration of 2%;

[0042] (2) Put the ultra-high molecular weight polyethylene fiber into the dispersion liquid for ultrasonic infiltration for 30 minutes;

[0043] (3) Take out the infiltrated ultra-high molecular weight polyethylene fibers and dry them, and perform irradiation treatment. The radiation source is a cobalt source, and the irradiation dose is 50kGy to obtain the modified ultra-high molecular weight polyethylene fibers.

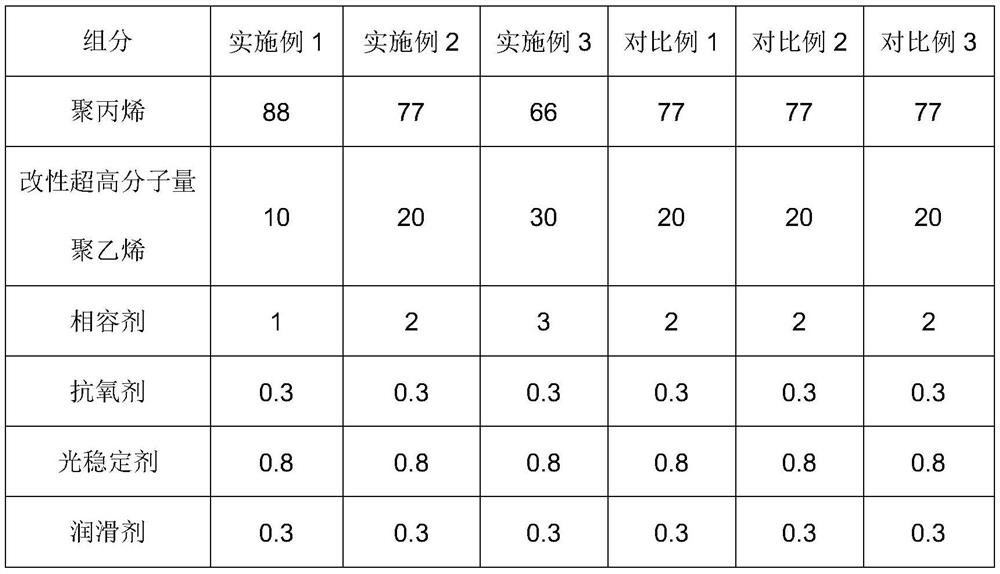

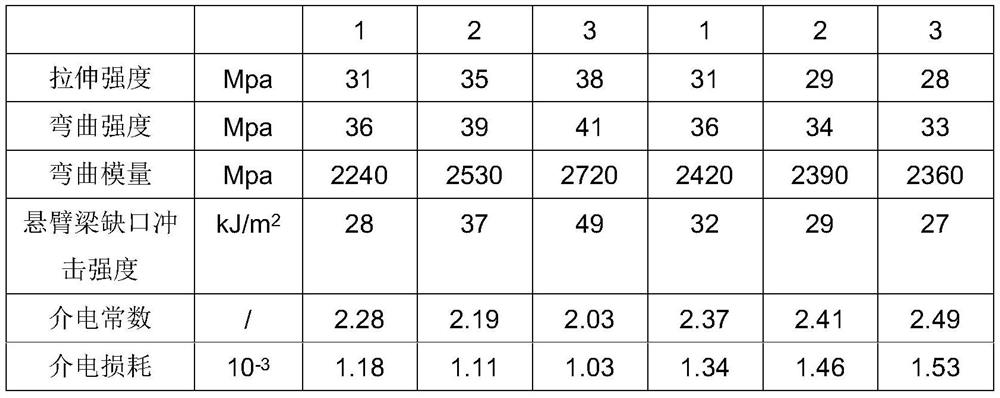

[0044] (4) Weigh each component according to the corresponding proportioning in Table 1, mix and mix polypropylene, compatibilizer, antioxidant, light stabilizer, lubricant, add twin-screw ex...

Embodiment 2

[0046] (1) Dissolve 5 parts of silane coupling agent in 95 parts of organic solvent aqueous solution (the organic solvent aqueous solution is obtained by blending distilled water and ethanol at a volume ratio of 1:1) to obtain a mixed solution; add 4 parts of porous nano-silica Stir evenly in 96 parts of the mixed solution to obtain a dispersion with a concentration of 4%;

[0047] (2) Put the ultra-high molecular weight polyethylene fiber into the dispersion liquid for ultrasonic infiltration for 30 minutes;

[0048] (3) Take out the infiltrated ultra-high molecular weight polyethylene fibers and dry them, and perform irradiation treatment. The radiation source is a cobalt source, and the irradiation dose is 80kGy to obtain the modified ultra-high molecular weight polyethylene fibers.

[0049] (4) Weigh each component according to the corresponding proportioning in Table 1, mix and mix polypropylene, compatibilizer, antioxidant, light stabilizer, lubricant, add twin-screw ext...

Embodiment 3

[0051] (1) Dissolve 8 parts of silane coupling agent in 92 parts of organic solvent aqueous solution (the organic solvent aqueous solution is obtained by blending distilled water and ethylene glycol at a volume ratio of 1:1) to obtain a mixed solution; 6 parts of porous nano-dioxide Silicon was added to 94 parts of the mixed solution and stirred evenly to obtain a dispersion with a concentration of 6%;

[0052] (2) Put the ultra-high molecular weight polyethylene fiber into the dispersion liquid for ultrasonic infiltration for 30 minutes;

[0053] (3) Take out the infiltrated ultra-high molecular weight polyethylene fibers and dry them, and perform irradiation treatment. The radiation source is a cobalt source, and the irradiation dose is 100kGy to obtain the modified ultra-high molecular weight polyethylene fibers.

[0054] (4) Weigh each component according to the corresponding proportioning in Table 1, mix and mix polypropylene, compatibilizer, antioxidant, light stabilizer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com