Whitening essence based on phospholipid-coated glabridin nanoemulsion and preparation method thereof

A technology of glabridin and nanoemulsion, which is applied in the field of daily chemicals to achieve the effects of good biocompatibility, increased compatibility and inhibition of tyrosinase production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

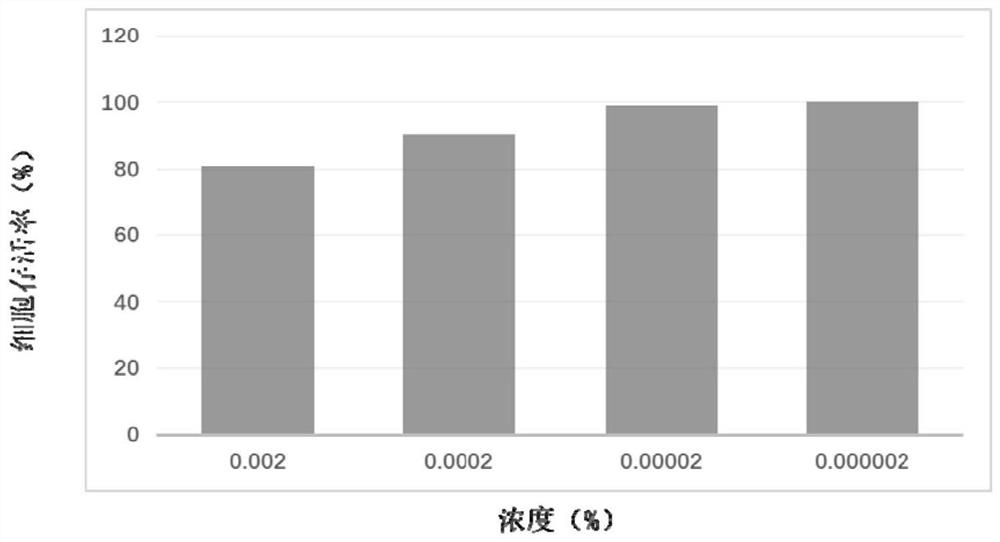

Image

Examples

Embodiment 1-3

[0040] A whitening essence based on phospholipid-encapsulated glabridin nanoemulsion, its raw material composition ratio, and the content of the raw material composition ratio in the control example are shown in Table 1 below.

[0041] The raw material component distribution ratio (unit: mass %) of table 1 embodiment 1

[0042]

[0043]

[0044] The preparation process of the above-mentioned whitening essence based on phospholipid-encapsulated glabridin nanoemulsion comprises the following steps:

Embodiment 1

[0046] 1) Preparation of phospholipid-coated glabridin nanoemulsion:

[0047] Dissolve phospholipids and glabridin in acetone at a mass ratio of 8:1, and stir evenly at 35°C; spray-dry the resulting solution to remove the organic solvent, and then freeze-dry for 11 hours to obtain the glabridin phospholipid complex; Tween20, co-emulsifier ethylene glycol, oil phase olive oil, glabridin phospholipid complex were ultrasonically mixed and injected into a high-pressure homogenizer together with deionized water, set the pressure at 100Mpa, and homogenized 4 times at 25°C. Nanoemulsion can be obtained.

[0048] 2) Wet and disperse glycerin, dipotassium glycyrrhizinate, acetylglucosamine, xanthan gum, sodium acrylate / sodium acryloyldimethyltaurate copolymer, and 1,3-butanediol in water in proportion, get the mixture;

[0049]3) Add a certain proportion of phospholipid-coated glabridin nanoemulsion, isononyl isononanoate, squalane, simethicone, isododecane, and p-hydroxyacetophenone...

Embodiment 2

[0052] 1) Preparation of phospholipid-coated glabridin nanoemulsion:

[0053] Dissolve phospholipids and glabridin in acetone at a mass ratio of 10:1, and stir evenly at 40°C; spray-dry the resulting solution to remove the organic solvent, and then freeze-dry for 12 hours to obtain the glabridin phospholipid complex; Poloxamer188, co-emulsifier propylene glycol, oil phase soybean oil, glabridin phospholipid complex are ultrasonically mixed and then injected into a high-pressure homogenizer together with deionized water, set the pressure at 80Mpa, and homogenize 4 times at 25°C Obtain nanoemulsion.

[0054] 2) Wet and disperse glycerin, dipotassium glycyrrhizinate, acetylglucosamine, xanthan gum, sodium acrylate / sodium acryloyldimethyltaurate copolymer, and 1,3-butanediol in water in proportion, get the mixture;

[0055] 3) Add a certain proportion of phospholipid-coated glabridin nanoemulsion, isononyl isononanoate, squalane, simethicone, isododecane, and p-hydroxyacetopheno...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com