Optical lens, preparation method thereof and application of optical lens in forked optical fiber device

A technology of optical lens and hard film layer, which is applied in the direction of optics, optical components, coatings, etc., can solve the problems of birefringence, thermal expansion and contraction effect, and it is difficult to meet the high quality requirements of optical lenses, etc., to achieve heat resistance Excellent performance, long service life, strong adhesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

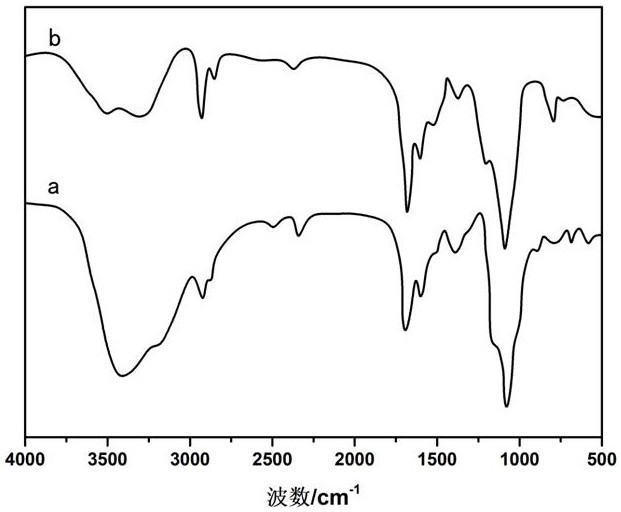

Image

Examples

Embodiment 1

[0047] The present embodiment provides a 4-amino-salicylic hydrazide-modified yellow humic acid, prepared by the following method to give:

[0048] 1 Huang parts by weight of the humic acid dispersed in water, the pH adjusted to 11 with a mass fraction of 20% sodium hydroxide solution, 0.6 parts by weight of formaldehyde was added, warmed to 85 ℃, 1.35 parts by weight of 4-amino-salicylic hydrazide, warmed to 95 deg.] C, the reaction for 3.5 h, allowed to cool to room temperature, 10% hydrochloric acid solution was adjusted to pH 4.5, heated to 100 deg.] C with a mass fraction of the reaction 5h, after the completion of the reaction, and dried at 60 deg.] C to obtain.

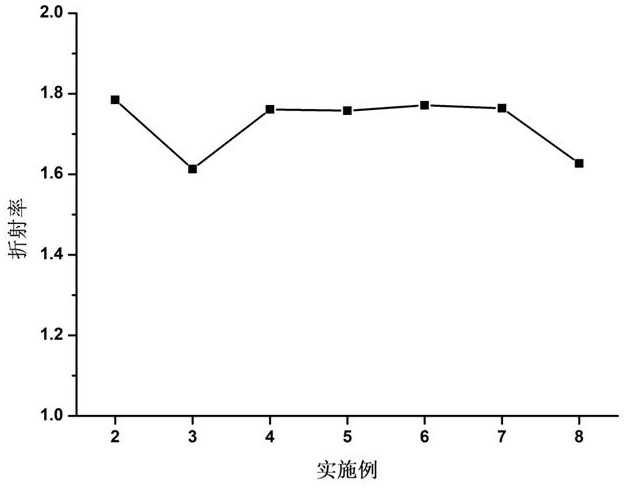

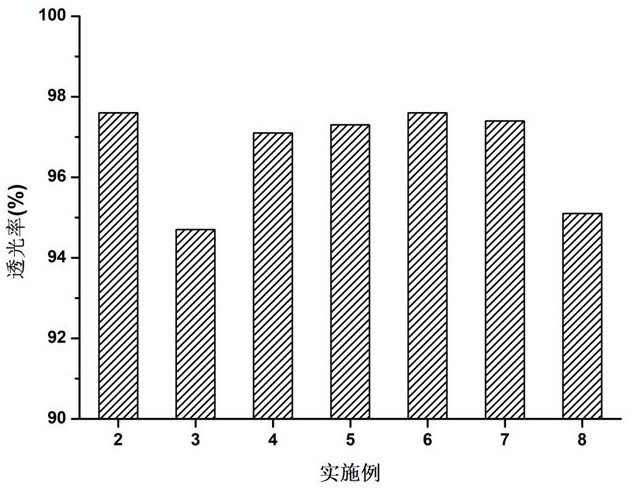

Embodiment 2

[0050] The present embodiment provides an optical lens prepared by the following method to give:

[0051] 1) Preparation of polyurethane resin: 1 part by weight of sorbitol, 0.08 obtained in Example 1 4-amino salicylic acid hydrazide-modified humate mixing parts by weight of yellow embodiment, flushed with nitrogen, dehydrated at 105 ℃ 2.5h, allowed to cool to 75 ℃, was added 0.4 parts by weight of diphenylmethane diisocyanate the reaction was stirred 2h, stirring rate 300r / min, cooled to room temperature, 0.04 parts by weight of triethylamine 40min, was added 4 parts by weight of deionized water were high speed stirred for 1.5h, stirring rate is 1500r / min, and finally at 50 deg.] C by rotary evaporation to give a polyurethane resin;

[0052] 2) pretreatment of a polycarbonate resin: The polycarbonate resin was placed malate / oxaloacetate mixed solution for 1h at 60 ℃, then washed with water, and dried 90 deg.] C, the mixed solution oxaloacetate mass fraction of 12%, mass fra...

Embodiment 3

[0056] The present embodiment provides another embodiment of an optical lens, which is prepared substantially the same as Example 2, except that, during preparation of the polyurethane resin, the use of unmodified yellow humic acid obtained in Example 1 was used instead of 4-amino-salicylic acid hydrazide modified yellow humic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com