Synthetic method of p-cyanophenol

A technology for p-cyanophenol and a synthesis method, which is applied in chemical instruments and methods, organic compound/hydride/coordination complex catalyst, ammonia-carboxylic acid reaction preparation, etc., can solve the problem of unsatisfactory reaction results and insufficient performance problems such as catalyst and filler promotion, to achieve the effect of improving compatibility and improving reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

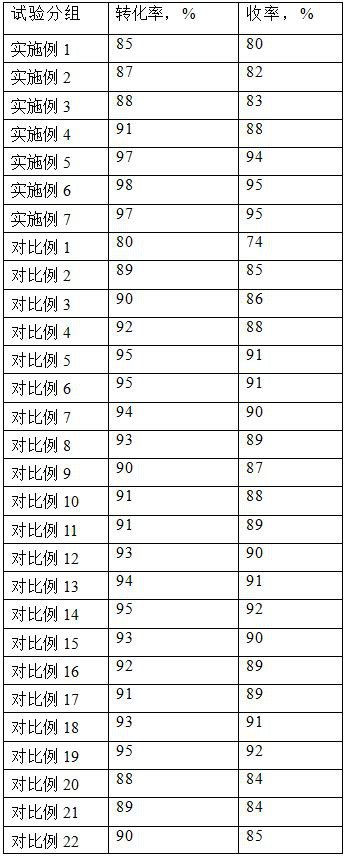

Examples

Embodiment 1

[0040]The present embodiment provides a kind of synthetic method of p-cyanophenol, concrete steps are:

[0041] The solid phosphoric acid catalyst is added in the reaction bed layer of the fixed bed reactor, then methyl p-hydroxybenzoate is dissolved in the solvent, fed together with water in the fixed bed reactor, and feeds ammonia into the reactor, The temperature of the reactor is controlled at 300°C, the pressure is above 0.06MPa, the material is discharged continuously, and the p-cyanophenol product is obtained through rectification and purification.

[0042] Among them, the mass ratio of methyl p-hydroxybenzoate and solid phosphoric acid catalyst is 1:0.1, the mass ratio of methyl p-hydroxybenzoate, solvent and water is 1:4:0.4, the flow rate of ammonia gas is 3L / min, and the solvent is pyridine.

[0043] The preparation method of solid phosphoric acid catalyst comprises the following steps:

[0044] (1) Put maleic anhydride, 1 / 2 long-chain alcohol, and silica microsph...

Embodiment 2

[0051] On the basis of embodiment 1, the present embodiment also provides a kind of synthetic method of p-cyanophenol, glass ball packing is also housed in the fixed bed reactor, and packing height is 30cm, and the surface treatment method of glass ball is:

[0052] S1. Soak the barite powder in 3 times the amount of sodium bicarbonate solution (mass concentration: 8%) for 1 hour, then evaporate the water under reduced pressure to obtain pretreated barite powder;

[0053] S2. Mix the thermosetting resin, sulfonic acid curing agent, silane coupling agent and the barite powder pretreated in step S1 to make a coating, and then spray it on the surface of the cleaned and dried glass ball with a spray thickness of 50 μm. , and then heated to 150°C for curing;

[0054] S3. Place the surface-cured glass balls in 40% hydrofluoric acid solution and soak them repeatedly for 4 times, each time for 20 minutes. After soaking each time, wash them with clear water, and finally dry them to obt...

Embodiment 3

[0058] On the basis of Example 2, this embodiment also discloses a synthetic method of p-cyanophenol, the thermosetting resin is a modified phenolic resin, and the preparation method of the modified phenolic resin is:

[0059] Mix the thermosetting phenolic resin with the solvent, then add bromine dropwise under stirring conditions, raise the temperature to 40°C and stir for 6 hours. After evaporating water, the obtained product is stirred and reacted with long-chain sodium alkoxide at room temperature for 2 hours. The obtained product is washed with water and dried. Finally, add dropwise the mixed solution of long-chain carboxylic acid and concentrated sulfuric acid, react at 110°C for 6 hours, and then remove the solvent to obtain the modified phenolic resin.

[0060] The solvent is diethylene glycol monobutyl ether, the added amount of concentrated sulfuric acid is 2%, and the molar ratio of thermosetting phenolic resin, bromine, long-chain sodium alkoxide, and long-chain ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com