Method for extracting and refining ecdysterone

A technology of ecdysterone and extract solution, which is applied in the field of natural compound extraction, can solve the problems of high concentration temperature, long concentration time, and large solvent residue, and achieve product purity and yield improvement, simplify post-processing requirements, and increase production speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

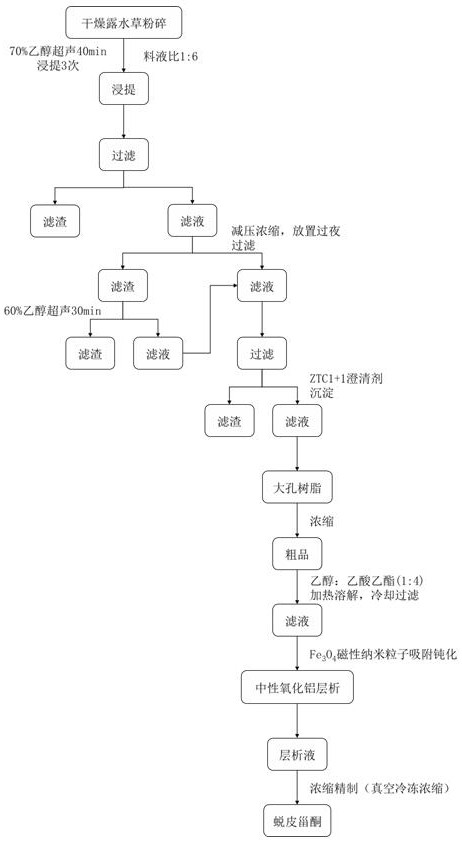

Method used

Image

Examples

Embodiment 1

[0056] In the traditional process of extracting ecdysterone from dry dew grass, water is usually used as a solvent for extraction, because water has good solubility for ecdysterone, which can effectively extract ecdysterone in dew grass to obtain crude product. However, as described in the background art, due to the high boiling point of water, the biological activity of ecdysterone is easily destroyed due to prolonged high temperature concentration when the crude product is concentrated in this solution. In addition, the art also uses toxic solvents such as methanol or acetone to extract ecdysterone. At present, it is rare to use ethanol to directly extract ecdysterone from dried dew grass.

[0057] This example discusses whether the ultrasonic leaching method can effectively replace the heating and refluxing leaching process.

[0058] Pulverize the dried dew grass, pass through a 60 mesh sieve, take 6g and divide it into two parts, each part is 3g, one part is placed in a d...

Embodiment 2

[0061] This case mainly discusses the extraction efficiency of ecdysterone from Dewweed by different concentrations of ethanol.

[0062] Pulverize the dried dew grass, pass through a 60-mesh sieve, take a portion of 3 g, add 180 g of ethanol or different concentrations of ethanol / water solution to a distillation flask, ultrasonicate for 20 min with an ultrasonic device, take out and filter, take a small amount of filtrate and centrifuge on a centrifuge, Spin at 10,000 r / min, centrifuge for 10 min, pass the supernatants of the two through the membrane, take 1 ml of each of the supernatants into a 25 ml volumetric flask, dilute to the mark with 50% ethanol, and inject 10 microliters into the high-performance liquid phase. In the chromatograph, the detection wavelength is 243nm, and the content of ecdysterone in the two liquids is compared by the size of the chromatogram area.

[0063]

[0064] By comparison, it can be seen that when the concentration of 65%~70% ethanol is use...

Embodiment 3

[0066] On the basis of Example 2, in order to further improve the utilization rate of dew grass raw materials, this example discusses whether it is necessary to perform 2 or 3 times of leaching.

[0067] The experimental operation is as in Example 2. In this example, ethanol with a concentration of 70% is used to extract the filter residues that have undergone different extraction times.

[0068]

[0069] The results show that 2-3 times are more reasonable extraction times. When only one extraction was performed, the filter residue still contained more ecdysterone residues, and the utilization rate of dew grass was not high. However, when the extraction times exceeded 4 times, the peak area of ecdysterone in the extract did not change significantly. Considering the effect of economy and impurities on the subsequent purification of ecdysterone, it was no longer necessary to re-extract the filter residue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com