Method for preparing ammonium tetramolybdate product through reverse extraction and impurity removal

A technology of ammonium tetramolybdate and products, applied in the preparation of molybdenum compounds, chemical instruments and methods, molybdenum compounds, etc., can solve the problems of complex organic phase composition, unfavorable industrialization realization, difficult phase separation, etc., and save acid and alkali consumption. , reduce or even eliminate the effect of good prospects for industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

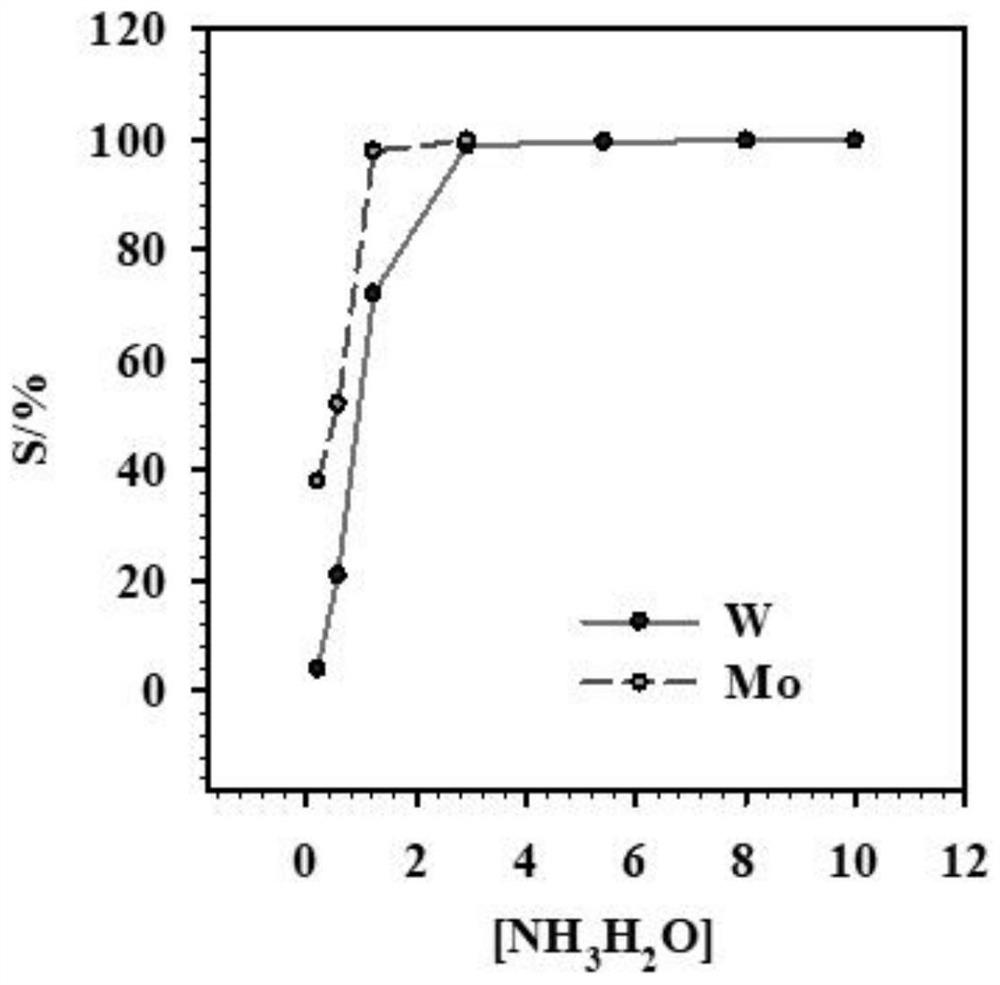

[0020] A loaded organic phase with a known load is used, wherein the composition of the organic phase is 25% N235 + 35% 2-octanol + 40% n-heptane, and the loaded organic phase is prepared by four times of material-liquid extraction obtained after treatment with a molybdenum catalyst. Among them, the extraction amount of molybdenum is 50g / L, and the loading amount of tungsten is 200mg / L. The back extraction experiment research is carried out, and the concentration of ammonia water is changed respectively, and the change of the back extraction efficiency is obtained as follows: figure 2 Shown: Under suitable alkalinity conditions, tungsten and molybdenum can be completely stripped.

Embodiment 2

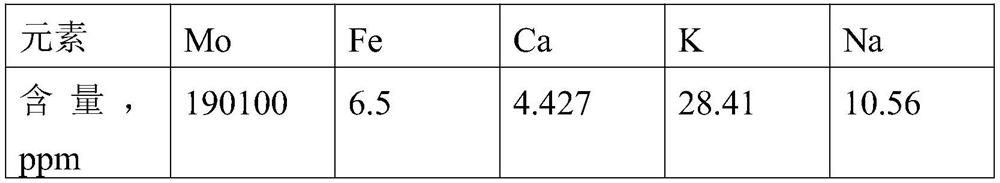

[0022] For a loaded organic phase: the composition of the organic phase is 15% N263 + 15% 2-octanol + 70% n-heptane, the feed liquid in contact with the organic phase is the leaching solution of nickel-molybdenum ore, and the loading amount of Mo loaded on the organic phase is 25g / L, other impurity loads are low, back extraction is carried out, the concentration of the back extraction solution is 4M ammonia water, the back extraction ratio is 8 / 1, the number of back extraction stages is 6, and the back extraction time is 5 minutes, the composition of the back extraction solution is as follows:

[0023] Table 1 Strip composition (ppm)

[0024]

Embodiment 3

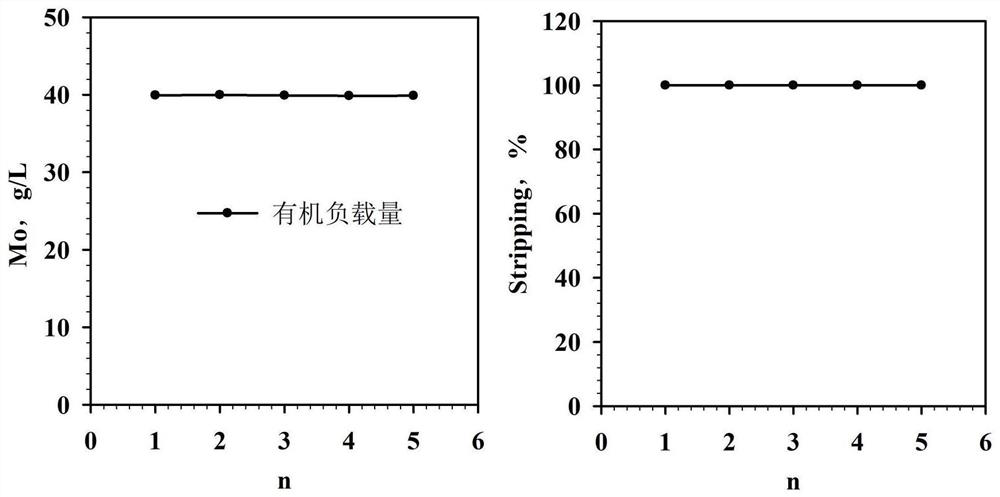

[0026] For a certain loaded organic phase: wherein the organic phase is composed of 20% N235+25% 2-octanol+55% kerosene, the feed liquid in contact with the organic phase is the leaching solution of ferromolybdenum flue ash, and the loading amount of Mo loaded on the organic phase is 40g / L, the load of other impurities is low, back extraction is carried out, the concentration of the back extraction solution is 3.8M ammonia water, the back extraction ratio is 4 / 1, the number of back extraction stages is 6, and the back extraction time is 4 minutes, the composition of the back extraction solution is as follows :

[0027] Table 2 Strip composition (ppm)

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com