Modified carbon black as well as preparation method and application thereof

A technology for modifying carbon black and carbon black, which is applied in textile/flexible product manufacturing, final product manufacturing, climate sustainability, etc., to achieve the effects of improving dispersibility, eliminating yellow light, and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

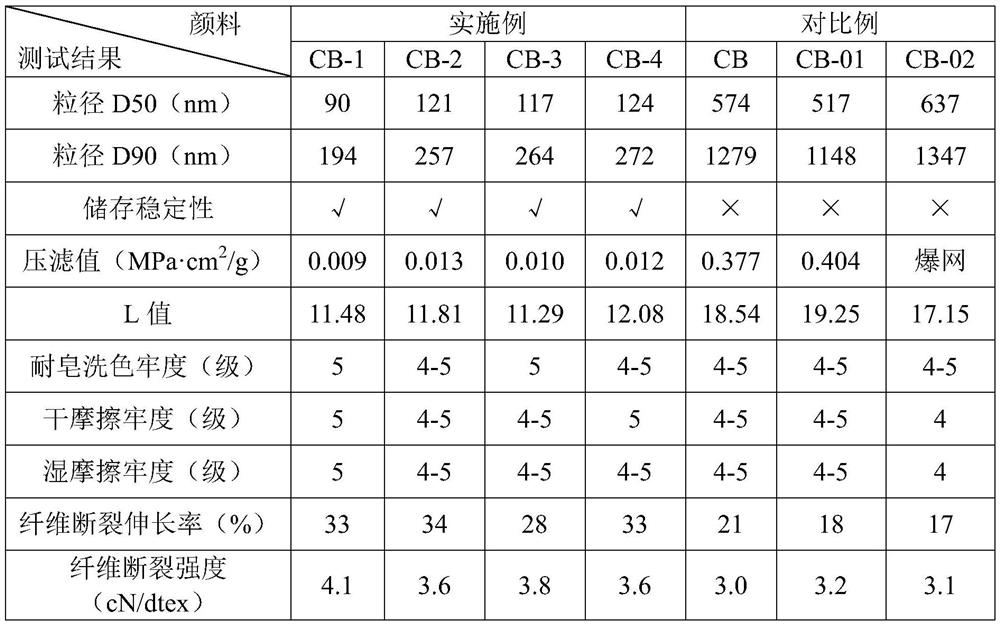

Examples

preparation example Construction

[0030] The present invention further provides a kind of preparation method of modified carbon black, comprises the steps:

[0031] (a) Add phthalocyanine to chlorosulfonic acid, carry out sulfonation reaction at a temperature of 130-150°C under the protection of an inert gas, the reaction time is 4-8 hours, then add thionyl chloride, at a temperature of 70-78 The chlorination reaction is carried out at ℃, and the reaction time is 1-3 hours; after the reaction is completed, the phthalocyaninesulfonyl chloride is obtained by cooling suction filtration in ice water and washing to neutrality; wherein, one phthalocyaninesulfonyl chloride molecule contains 2 to 4 a sulfonyl chloride group; in this step (a), the molar ratio of phthalocyanine, chlorosulfonic acid and sulfur oxychloride is 1: (20~30): (5~10); wherein phthalocyanine is metal-free Phthalocyanine or metal phthalocyanine, wherein the metal can be copper, iron, cobalt, aluminum, nickel, calcium, sodium, magnesium, zinc, etc.,...

Embodiment 1

[0037] (a) Add 1 mol of copper phthalocyanine to 25 mol of chlorosulfonic acid, carry out sulfonation reaction at 140°C under nitrogen protection for 6 hours; then add 8 mol of thionyl chloride, carry out chlorination reaction at 75°C for 2 hours ; Suction filtration in ice water and washing to neutrality to obtain phthalocyanine sulfonyl chloride; wherein, one phthalocyanine sulfonyl chloride molecule contains an average of 3.8 sulfonyl chloride groups.

[0038] (b) Add 1 mol of phthalocyanine sulfonyl chloride obtained in step (a) into ice water to disperse evenly, adjust the pH value to 8.5 with ammonia water, add 2.8 mol of modified additives containing polyether chains and 1 mol of pyridine, at a temperature of 30 React at ℃ for 6h, filter and dry to obtain phthalocyanine derivatives containing sulfonyl chloride groups and polyether chains; wherein, the modified additive is NH 2 (OC 2 h 4 ) n OH, the molecular weight is 3400.

[0039] (c) 0.2 parts of phthalocyanine d...

Embodiment 2

[0041] (a) Add 1 mol copper phthalocyanine to 20 mol chlorosulfonic acid, carry out sulfonation reaction at a temperature of 150°C under nitrogen protection for 4 hours; then add 10 mol of thionyl chloride, carry out chlorination reaction at a temperature of 73°C for 3 hours Suction filtration and washing in ice water to neutrality to obtain phthalocyanine sulfonyl chloride; wherein, one phthalocyanine sulfonyl chloride molecule contains an average of 2.0 sulfonyl chloride groups;

[0042] (b) 1mol phthalocyanine sulfonyl chloride obtained in step (a) is added to ice water to disperse evenly, adjust the pH value to 8.0 with ammonia water, add 1.0mol of modified additives containing polyether chains and 1mol pyridine, at a temperature of React at 25°C for 8 hours, filter and dry to obtain phthalocyanine derivatives containing sulfonyl chloride groups and polyether chains; wherein, the modified additive is NH 2 (OC 2 h 4 ) n OH, the molecular weight is 1000;

[0043] (c) 0.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com