Reversible crosslinked ethylene propylene diene monomer and preparation method thereof

A technology of EPDM rubber and EPDM rubber, which is applied in the field of polymer materials, can solve the problems of reducing the fluidity of rubber processing, self-crosslinking, and poor mechanical properties of hydrogen-bonded rubber, and achieve excellent tensile strength properties , high elongation at break, and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

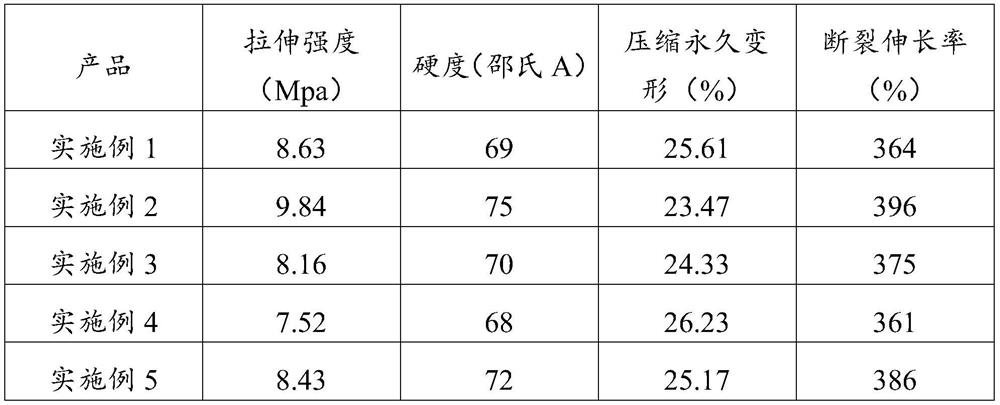

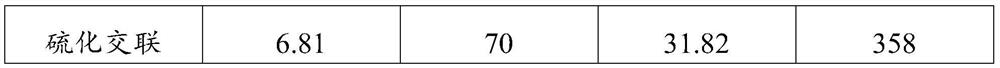

Examples

Embodiment 1

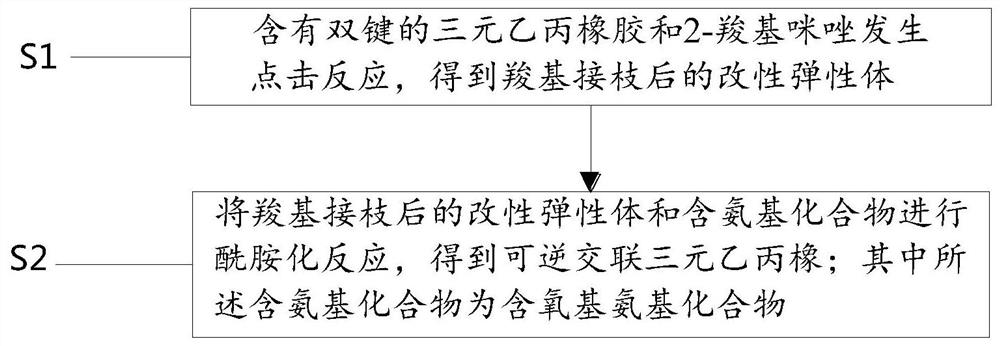

[0022] Such as figure 1 Shown, a kind of preparation method of reversible cross-linked EPDM rubber comprises the following methods:

[0023] S1, EPDM rubber containing double bonds and 2-carboxyimidazole undergo a click reaction to obtain a modified elastomer after carboxyl grafting;

[0024] S2. Carboxyl-grafted modified elastomer and amino-containing compound are subjected to amidation reaction to obtain reversibly cross-linked EPDM; wherein the amino-containing compound is an oxygen-containing amino compound.

[0025] details as follows:

[0026] Add 1 mole part of EPDM rubber containing double bonds into the tetrahydrofuran solution, then add 0.01 mole part of 2-carboxyimidazole for mixing, and then add appropriate amount of methacrylic acid, benzoin dimethyl ether, dialkoxy Acetophenone, ferrocene-tetrafluoroborate, after mixing evenly, a click reaction occurs under the condition of ultraviolet light irradiation, and the modified elastomer after carboxyl grafting is obt...

Embodiment 2

[0029] A reversible cross-linked EPDM rubber is prepared by the following reversible cross-linked EPDM rubber preparation method, including the following methods:

[0030] Add 1 mole part of EPDM rubber containing double bonds to N-methyl-pyrrolidone solution, then add 0.1 mole part of 2-carboxyimidazole for mixing, and then add appropriate amount of maleic anhydride, benzoin bimethyl Ether, benzophenone, and triphenylhexafluoroantimonate sulfonium salt, after mixing evenly, a click reaction occurs under ultraviolet light irradiation conditions to obtain a modified elastomer after carboxyl grafting, in which maleic anhydride, benzoin bis The mass ratios of methyl ether, benzophenone, and triphenylhexafluoroantimonate sulfonium salt to the total mixed solution are 8%, 0.5%, 0.3%, and 0.02% respectively

[0031] Take 1 mole part of the above-mentioned modified elastomer obtained after carboxyl grafting and dissolve it in N-methyl-pyrrolidone solution, and then add 0.1 mole part ...

Embodiment 3

[0033] A reversible cross-linked EPDM rubber is prepared by the following reversible cross-linked EPDM rubber preparation method, including the following methods:

[0034] Add 1 mole part of EPDM rubber containing double bonds to N,N'-dimethylformamide solution, then add 1 mole part of 2-carboxyimidazole for mixing, and then add appropriate amount of acrylic acid and benzoin Dimethyl ether, xanthone, ferrocene-tetra-fluoroborate, after mixing evenly, click reaction occurs under the condition of ultraviolet light irradiation, to obtain the modified elastomer after carboxyl grafting, in which acrylic acid, benzoin bimethazine Ether, dialkoxyacetophenone, and ferrocene-tetrafluoroborate account for 10%, 0.5%, 0.3%, and 0.02% of the total mixed solution by mass, respectively.

[0035] Take 1 mole part of the above-mentioned modified elastomer obtained after carboxyl grafting and dissolve it in N, N'-dimethylformamide solution, and then add 1 mole part of N-(2-acetamido)-2 - tauri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com