Rare earth nucleating agent and preparation method and application thereof as well as high-crystallinity modified polylactic acid film and preparation method and application thereof

A technology of high crystallinity and nucleating agent, applied in the field of packaging materials, can solve the problems of uneven crystallization of polylactic acid, poor compatibility of polylactic acid, poor product quality, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

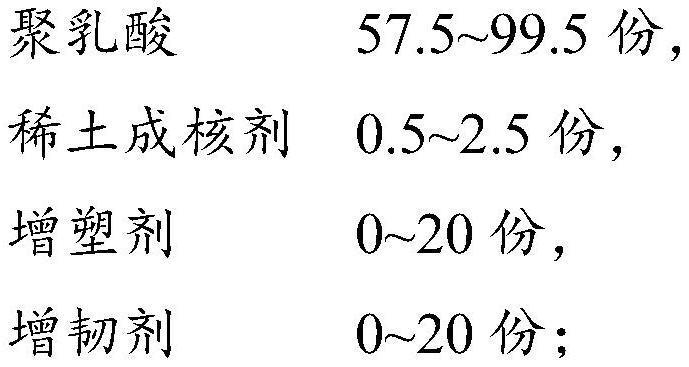

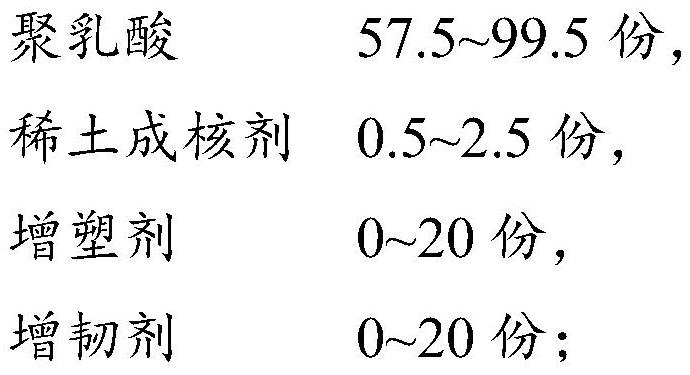

Method used

Image

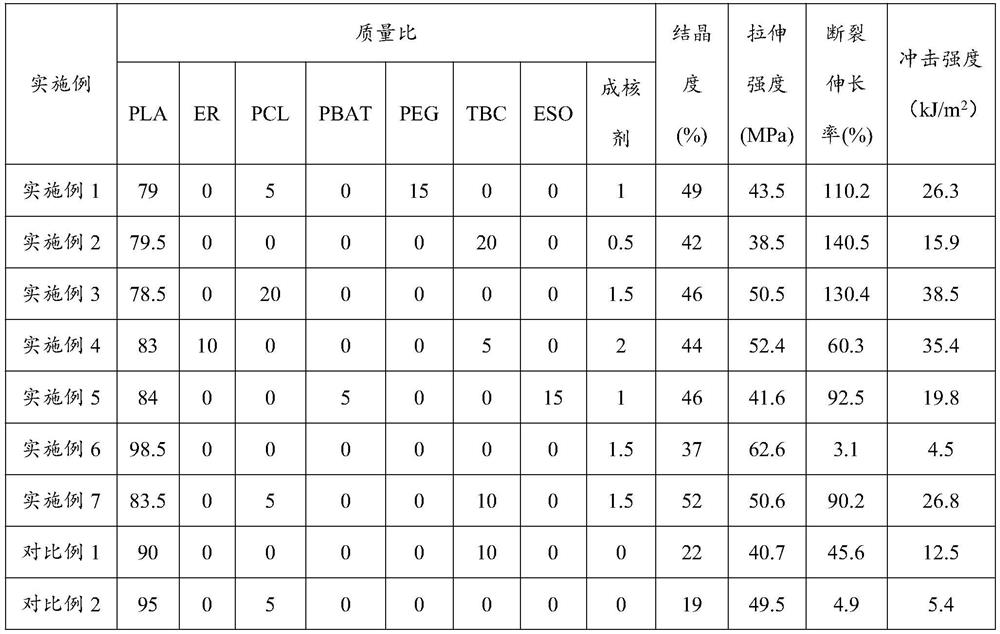

Examples

preparation example Construction

[0035] The present invention provides the preparation method of the rare earth nucleating agent described in the above technical scheme, comprising the following steps:

[0036] Mixing a ligand compound, a surfactant, a coupling agent and water to obtain a first solution; the ligand compound includes lactic acid and / or sodium lactate;

[0037] Dissolving the rare earth compound to obtain a second solution; the rare earth compound includes one or more of rare earth nitrate, rare earth chloride and rare earth oxalate;

[0038] The second solution is added dropwise to the first solution for coordination reaction to obtain a precipitate; the precipitate is successively centrifuged, filtered and dried to obtain the rare earth nucleating agent.

[0039] In the present invention, the ligand compound, surfactant, coupling agent and water are mixed to obtain the first solution. In the present invention, the ligand compound includes lactic acid and / or sodium lactate; the present invent...

Embodiment 1

[0062] (1) Preparation of rare earth nucleating agent

[0063] The pH value of the aqueous lactic acid solution (55% in mass concentration) was adjusted to 7, and then the adjusted pH value of the aqueous lactic acid solution, the biosurfactant sophorolipid and the silane coupling agent KH550 were added to a three-necked flask to obtain the first solution;

[0064] Cerium nitrate is dissolved in ethanol to obtain a second solution;

[0065] Control the heating temperature of the water bath to 30°C, gradually add the second solution to the first solution dropwise, the molar ratio of cerium nitrate, lactic acid, sophorolipid and KH550 is 1:3:0.002:0.002, and the second solution is within 0.5h After dripping, stir for 2 hours to carry out coordination reaction to obtain white precipitate of cerium lactate; centrifuge and filter the white precipitate of cerium lactate, and then dry it in a vacuum oven at 70°C for 24 hours to obtain cerium lactate powder, which is the rare earth nu...

Embodiment 2

[0070] (1) Preparation of rare earth nucleating agent

[0071] The pH value of the sodium lactate aqueous solution (mass concentration is 60%) is adjusted to 8, then the sodium lactate aqueous solution after the pH value adjustment, the nonionic surfactant polyoxyethylene fatty alcohol ether and the silane coupling agent KH560 are added in the three-necked flask, obtain the first solution;

[0072] Lanthanum chloride is dissolved in isoamyl alcohol to obtain a second solution;

[0073] Control the heating temperature of the water bath to 40°C, gradually add the second solution to the first solution dropwise, the molar ratio of lanthanum chloride, sodium lactate, polyoxyethylene fatty alcohol ether and KH560 is 1:4:0.002:0.005, the second solution Finish dropping within 1 hour, and stir for 5 hours after dropping to carry out coordination reaction to obtain a white precipitate of lanthanum lactate; centrifuge and filter the white precipitate of lanthanum lactate, and then dry it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com