Modified electrode and preparation method and application thereof

An electrode and modification technology, applied in the field of materials, can solve problems such as poor safety, unfriendly environment, and decreased device cycle stability, achieve improved energy density and power density, widen the voltage window, and meet the requirements of high-performance supercapacitors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] The preparation method of the aqueous high-voltage supercapacitor has strong universality, does not require too fine regulation and a large amount of additives, and has the potential and value of industrial mass production.

[0058] Sample Characterization

[0059] Use scanning electron microscope and transmission electron microscope to collect sample morphology and ultrastructure information, use X-ray energy spectrometer to collect sample element and distribution information, use electrochemical workstation to perform in-situ electrochemical deposition and electrode electrochemical performance characterization analysis , using the blue electric battery test system to characterize the electrode performance of the sample.

Embodiment 1

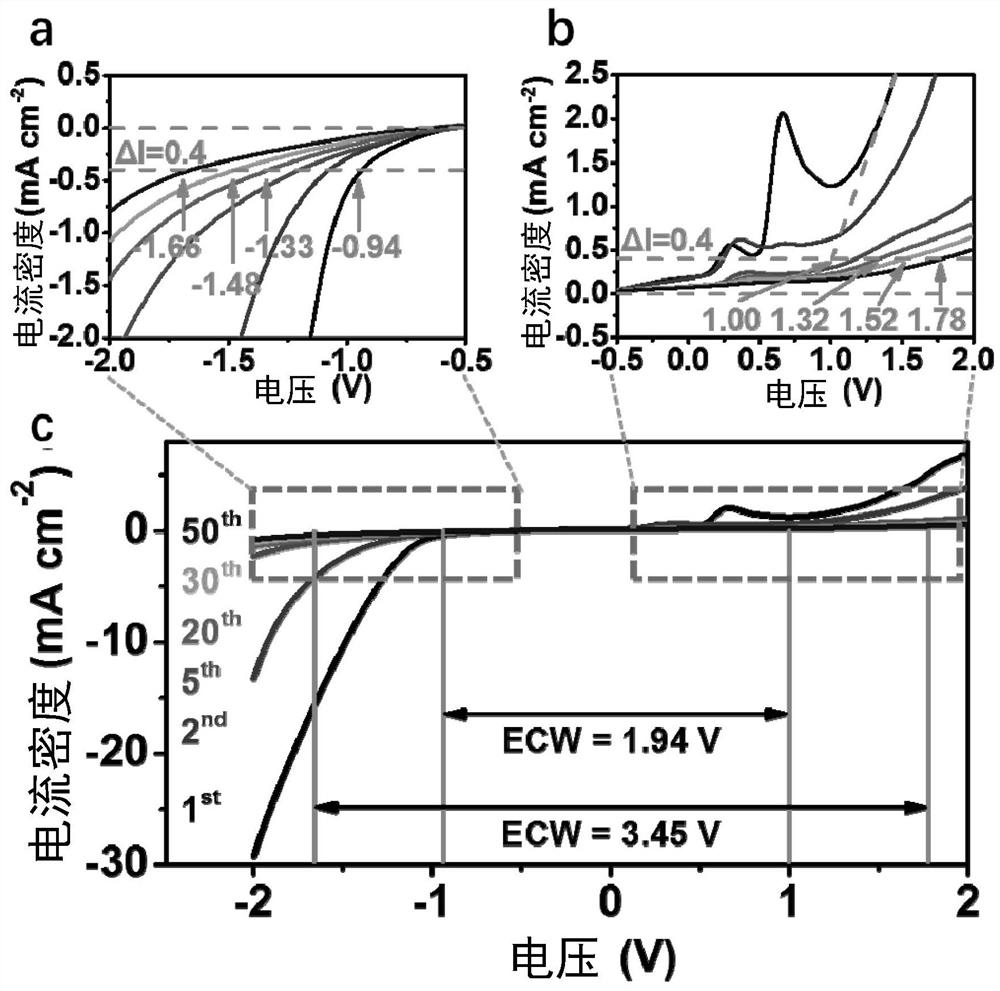

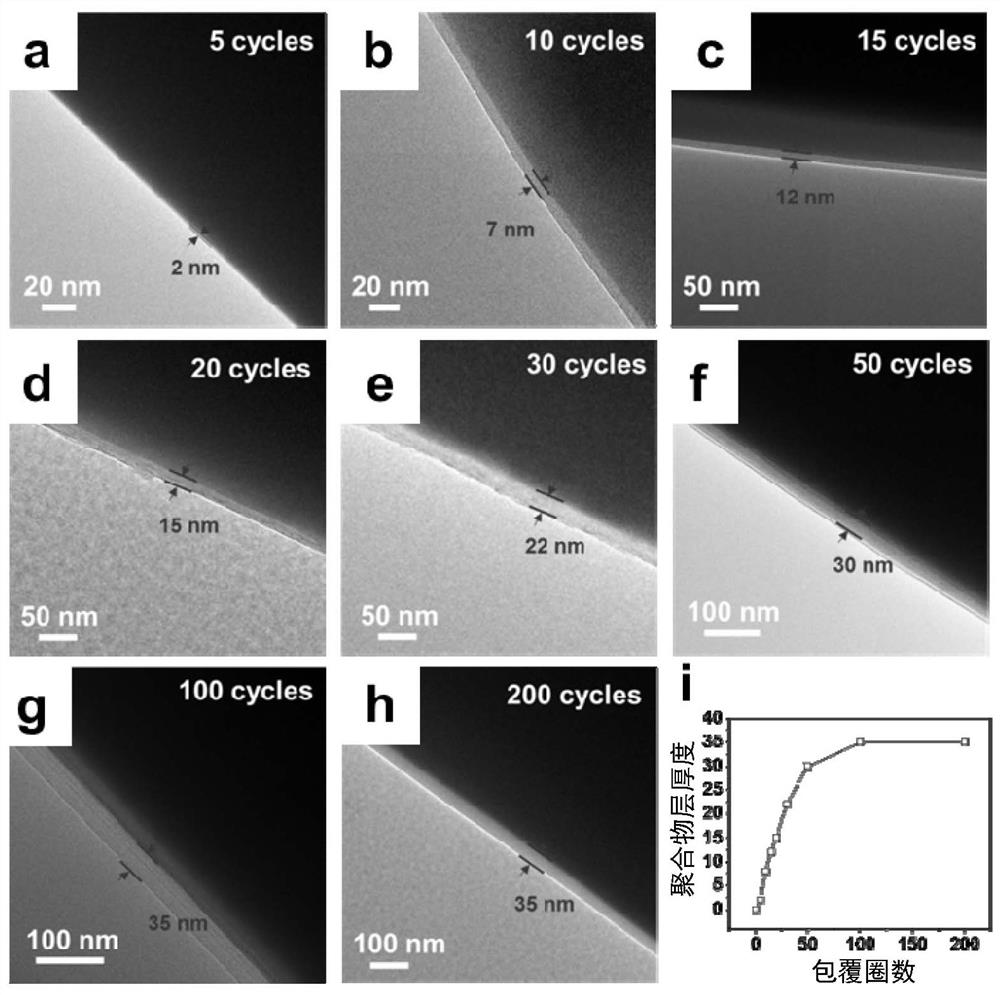

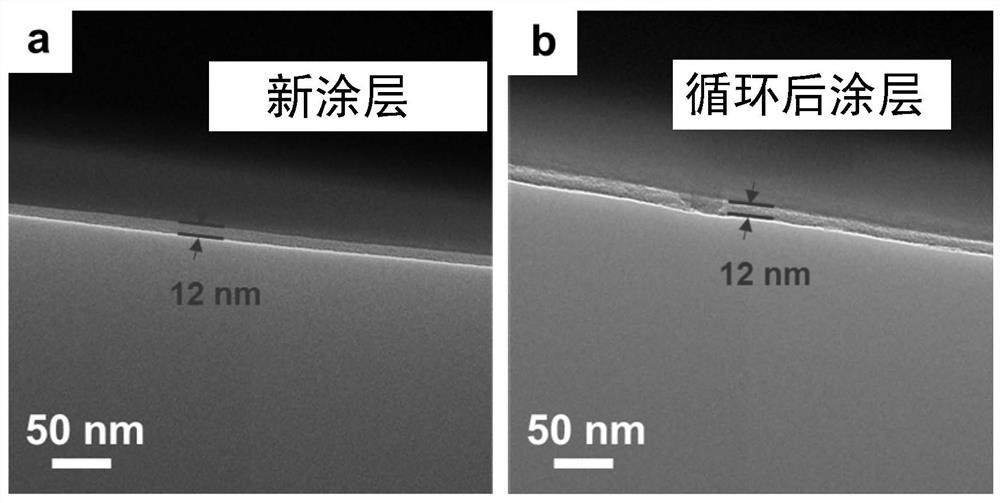

[0062] A blank carbon felt (CCF) current collector that does not load active substances is firstly used to electrochemically deposit a polymer of small molecule organic monomers and their salts containing carbon-carbon double bonds. Put the blank carbon felt electrode into 2mol / L of lithium acrylate solution as the working electrode, Ag / AgCl as the reference electrode, and graphite as the counter electrode. Cyclic voltammetry (CV) was used to deposit lithium polyacrylate on the electrode surface in situ, and the scanning range was set to -2V~ 2V, the scanning speed is 50mV / s, and the number of scanning circles is 1, 2, 5, 10, 15, 20, 30, 50, 100, 200. Such as figure 1 As shown, as the number of CV cycles increases, the electrochemical window of the electrode gradually widens from 1.94V to 3.45V. Such as figure 2 As shown, the transmission electron microscopy characterization shows that with the increase of the number of cycles, the thickness of the polymer layer on the sur...

Embodiment 2

[0064] The carbon felt electrode loaded with YP-50 type activated carbon (the load of YP-50 type activated carbon is 1mg / cm 2 ) into a 2mol / L lithium acrylate solution as the working electrode, Ag / AgCl as the reference electrode, and graphite as the counter electrode. Cyclic voltammetry (CV) is used to deposit lithium polyacrylate on the electrode surface in situ, and the scanning range is set It is -1.6V~1.6V, the scanning speed is 50mV / s, and the number of scanning circles is 20 circles, such as Figure 4 shown. After the in-situ deposition is completed, the electrode is rinsed with deionized water to remove the lithium acrylate monomer adhered to the electrode. Then put the above-mentioned treated electrode into a 2mol / L lithium sulfate electrolyte with a pH of about 6-8, use Ag / AgCl as the reference electrode, graphite as the counter electrode, and test the in-situ coated lithium polyacrylate electrode electrochemical properties such as Figure 5 As shown in a, the elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com