A kind of composite nanoparticle steel bar rust inhibitor and preparation method thereof

A technology of composite nanoparticles and steel bar rust inhibitor, applied in the field of steel bar corrosion protection, can solve problems such as weak effect, and achieve the effect of reducing spillage, excellent environmental performance, biocompatibility, and durability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

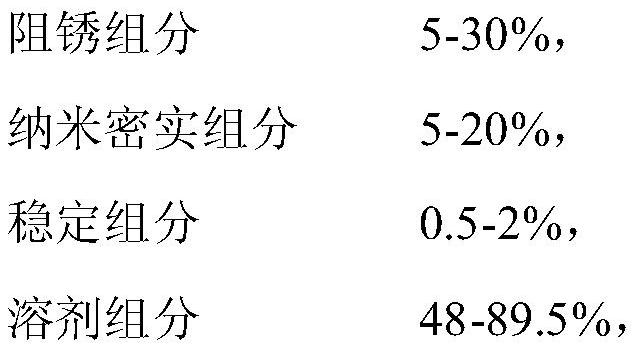

[0035] A composite nanoparticle rust inhibitor for steel bars, comprising: a mass fraction ratio of a rust inhibitor component, a nano compact component, a stabilizing component and a solvent component of 20:5:0.5:74.5;

[0036] The rust inhibitor component is prepared by mixing polyaspartic acid, sodium phosphate, calcium zincate, sodium ammonium octadecanoate and amino acid mixture in a mass ratio of 10:0.1:0.05:0.05:4.5;

[0037] The amino acid mixture is formed by mixing aspartic acid, aspartame, amino acid, proline, phenylalanine and other mass ratios;

[0038] The nano-dense component is nano-alumina dispersion, wherein the particle size of nano-alumina is 30nm, and the mass fraction is 20%;

[0039] The stabilizing component is composed of sorbitol ester and pentaerythritol ester, and its mass fraction ratio is 1:1;

[0040] The solvent component is water.

[0041] The preparation method of described steel bar rust inhibitor is as follows:

[0042] (1) Heat the water...

Embodiment 2

[0045]A composite nanoparticle rust inhibitor for steel bars, comprising: a mass fraction ratio of a rust inhibitor component, a nano compact component, a stabilizing component and a solvent component of 20:10:1:69;

[0046] The rust-inhibiting components are composed of polyaspartic acid, sodium monohydrogen phosphate, zinc nitrate, sodium zincate, serine, lysine, and arginine in mass ratio: 13.6:0.05:0.05:0.1:2:2 : 2 mixed;

[0047] The nano-compact component is a nano-silica dispersion, wherein the particle size of the nano-silica is 50 nm and the mass fraction is 25%;

[0048] The stabilizing component is a mixture of glycerol monostearate and laurate, and the mass fraction ratio is 2:1;

[0049] The solvent component is water;

[0050] The preparation method of described steel bar rust inhibitor is as follows:

[0051] (1) Heat the water to 45°C, add the stabilizing component while stirring and mix well for 0.5 hours, then add the rust inhibitor component, and stir at ...

Embodiment 3

[0054] A composite nanoparticle rust inhibitor for steel bars, comprising: a mass fraction ratio of a rust inhibitor component, a nano compact component, a stabilizing component and a solvent component of 30:5:0.5:64.5;

[0055] The rust inhibitor component is prepared by mixing polyaspartic acid, ammonium dihydrogen phosphate, zinc sulfate and amino acid mixture in a mass ratio of 20:0.25:0.25:9.5;

[0056] The amino acid mixture is prepared by mixing glycine, alanine, leucine, isoleucine and histidine in a mass fraction ratio of 1:1:1:1:1:1.

[0057] The nano-compact component is a nano-silica dispersion, wherein the particle size of the nano-silica is 50 nm and the mass fraction is 25%;

[0058] Described stabilizing component is glycerol monostearate;

[0059] The solvent component is water;

[0060] The preparation method of described steel bar rust inhibitor is as follows:

[0061] (1) Heat the solvent to 45°C, add the stabilizing component while stirring and mix well...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com