Secondary battery

A secondary battery and electrolyte technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve problems such as the decline in the effective transmission capacity of ions and electrons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0099]

[0100]The present invention also provides a method for preparing the above-mentioned negative electrode sheet, the method comprising the following steps:

[0101] The solvent, the negative electrode active material, the conductive agent, the binder and the additive are uniformly mixed to prepare the negative electrode slurry; the negative electrode slurry is coated on the surface of the negative electrode current collector and dried to prepare the negative electrode sheet.

[0102] In one solution of the present invention, the negative electrode slurry contains 150-350 parts by mass of solvent, 73-98.5 parts by mass of negative electrode active material, 0.5-15 parts by mass of conductive agent, 0.001-2 parts by mass of additives, 0.999-10 parts by mass of binder.

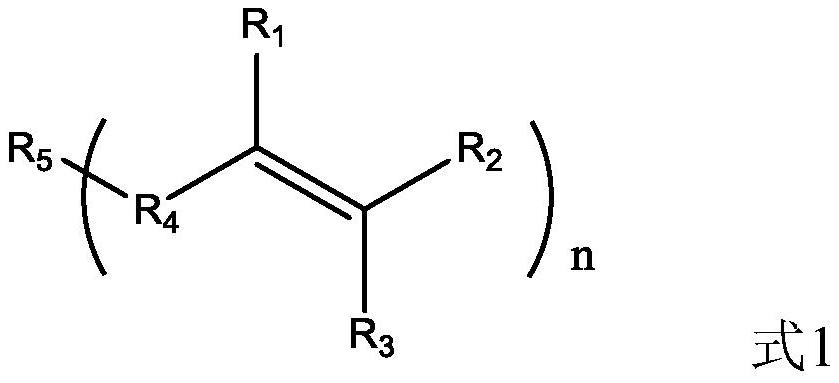

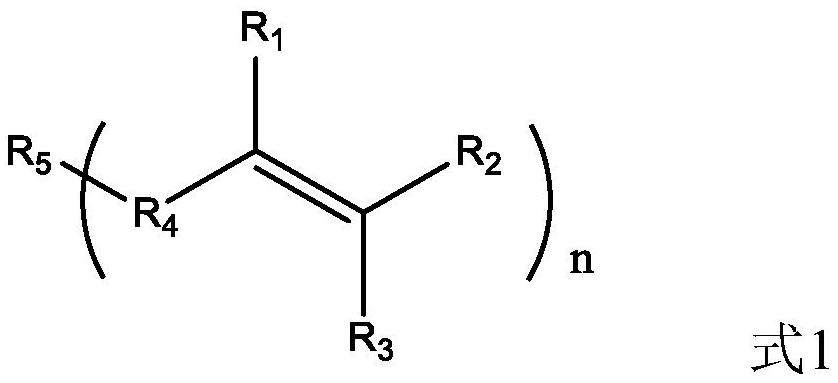

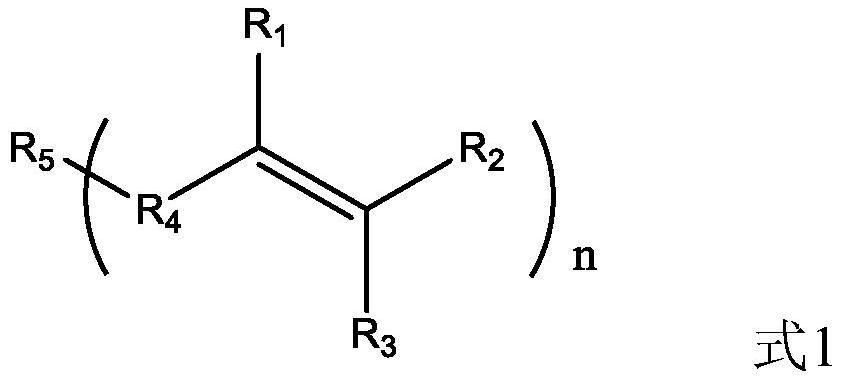

[0103] In one embodiment of the present invention, the solvent is at least one selected from water, acetonitrile, benzene, toluene, xylene, acetone, tetrahydrofuran, hydrofluoroether, and N-methylpyrroli...

Embodiment 1

[0140] 1) Preparation of positive pole piece:

[0141] Mix 96g positive electrode active material nickel-cobalt-manganese ternary material (NCM811), 1.5g binder polyvinylidene fluoride (PVDF), 1.5g conductive carbon black, 1g conductive carbon nanotubes, add 150g N-methyl Pyrrolidone (NMP) was stirred under the action of a vacuum mixer until the mixed system formed a positive electrode slurry with uniform fluidity; the positive electrode slurry was uniformly coated on an aluminum foil with a thickness of 13 μm; after being dried at 100°C for 36 hours, pumping The pole piece is obtained after vacuum treatment, and the pole piece is rolled and cut to obtain the positive pole piece;

[0142] 2) Preparation of negative pole piece:

[0143] 50g natural graphite, 23g silicon oxide, 10g conductive agent single-walled carbon nanotube (SWCNT), 5g conductive agent conductive carbon black (SP), 2g diethyl diallylmalonate, 4g binder carboxymethyl Base cellulose sodium (CMC), 6g binder s...

Embodiment 2-6

[0152] Embodiment 2-6 and other comparative examples

[0153] The specific processes of Examples 2-6 and other comparative examples refer to Example 1. The main differences are the process conditions of the negative electrode sheet, the amount of each component added, and the type of each component material. See Table 1 and Table 2 for details.

[0154] The composition of the negative pole sheet of table 1 embodiment and comparative example

[0155]

[0156]

[0157] The composition of the negative pole sheet of table 2 embodiment and comparative example

[0158]

[0159] Carry out performance test to the battery that above-mentioned embodiment and comparative example prepare:

[0160] (1) Battery internal resistance AC impedance test method: use Metrohm Swiss Metrohm PGSTAT302N chemical workstation in the range of 100KHz-0.1mHz, 25°C to conduct AC impedance test on 50% SOC lithium-ion battery, the test results are listed in Table 3 .

[0161] The battery internal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Single sided density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com