Method for preparing large-area high-performance n-type two-dimensional molybdenum telluride field effect transistor array

A transistor array and molybdenum telluride field technology, which is applied in the field of preparing large-area high-performance n-type two-dimensional molybdenum telluride field effect transistor arrays, can solve problems such as unsatisfactory doping effects, achieve low contact resistance, and improve injection efficiency , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further elaborated below through specific implementation examples in conjunction with the accompanying drawings.

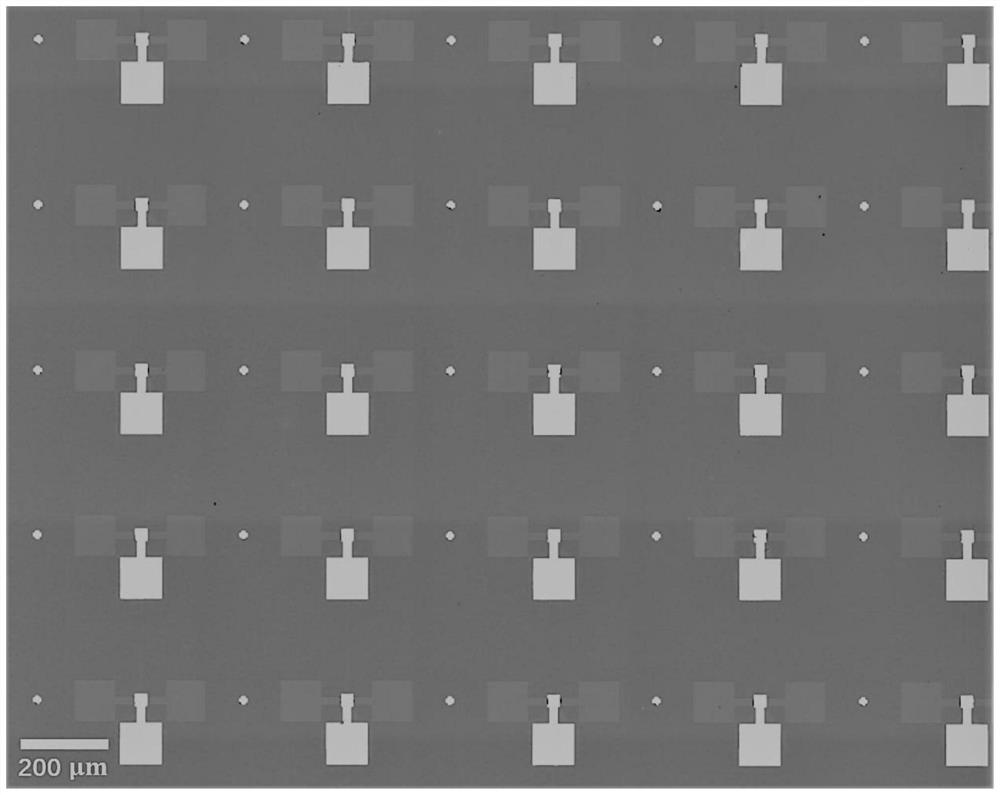

[0028] In this embodiment, the method for preparing a large-area high-performance n-type two-dimensional molybdenum telluride field-effect transistor array includes the following steps:

[0029] 1) Prepare silicon / silicon oxide substrate, SiO 2 The thickness is 285nm.

[0030] 2) A molybdenum thin film with a thickness of about 2 nm is deposited on the substrate by magnetron sputtering.

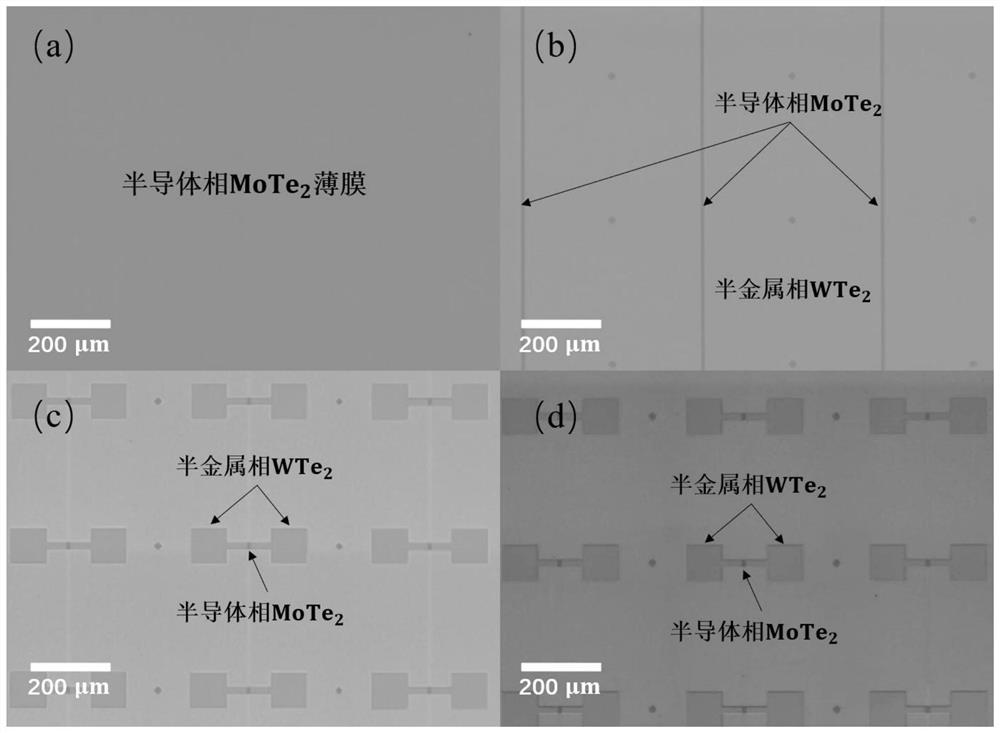

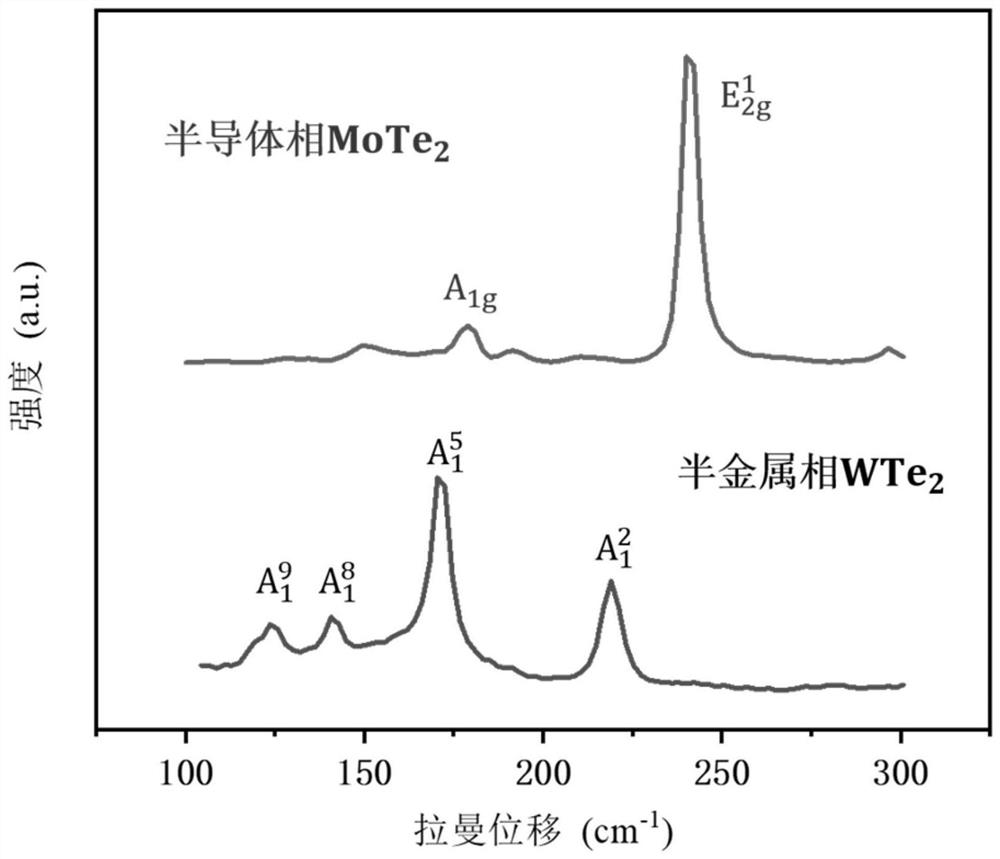

[0031] 3) Carry out chemical vapor deposition to the sample: put appropriate amount of tellurium powder and the sample in the quartz boat, then put the quartz boat into the tube furnace, so that the tellurium powder flows up the sample; keep the airflow of 7 sccm hydrogen and 5 sccm argon, heat tube furnace to raise the temperature to 630°C after 20 minutes, keep the chamber at a constant temperature for 3 hours, and then cool down to room t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com