Preparation method of composite nano carbon material and composite nano material

A nano-carbon material and composite technology, applied in the direction of nano-carbon, carbon nanotubes, nanotechnology, etc., can solve the problems of poor conductive network and low production efficiency, and achieve the goal of increasing yield, improving dispersion, and improving agglomeration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

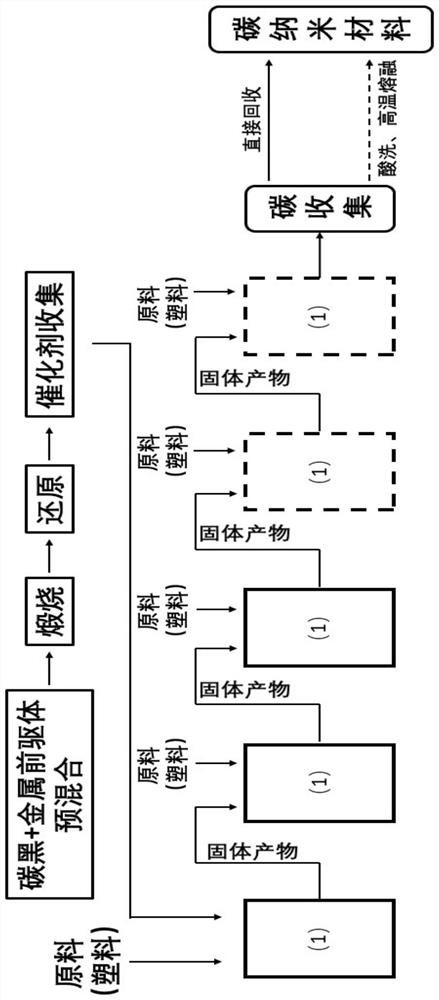

[0101] After the research of the inventors, it was found that the existing catalysts for preparing nano-carbon materials cannot be applied to microwave treatment, and microwave catalysis is used more and more in material preparation. For carbon chain polymers such as plastics with complex structures , simple one-step microwave treatment is difficult to achieve high yield of carbon nanomaterials, and microwave power has a great influence on the yield, purity and quality of carbon nanomaterials, the yield of carbon nanomaterials by multi-step microwave treatment with equal power Improvement is also very limited, and high-power multi-step microwave treatment also easily causes the purity or quality of nano-carbon materials to be adversely affected. Therefore, the present invention provides a method such as Figure 1 to Figure 6 The preparation method of the composite nano-carbon material and the composite nano-material include: preparing a catalyst; mixing the raw material and the...

Embodiment 1

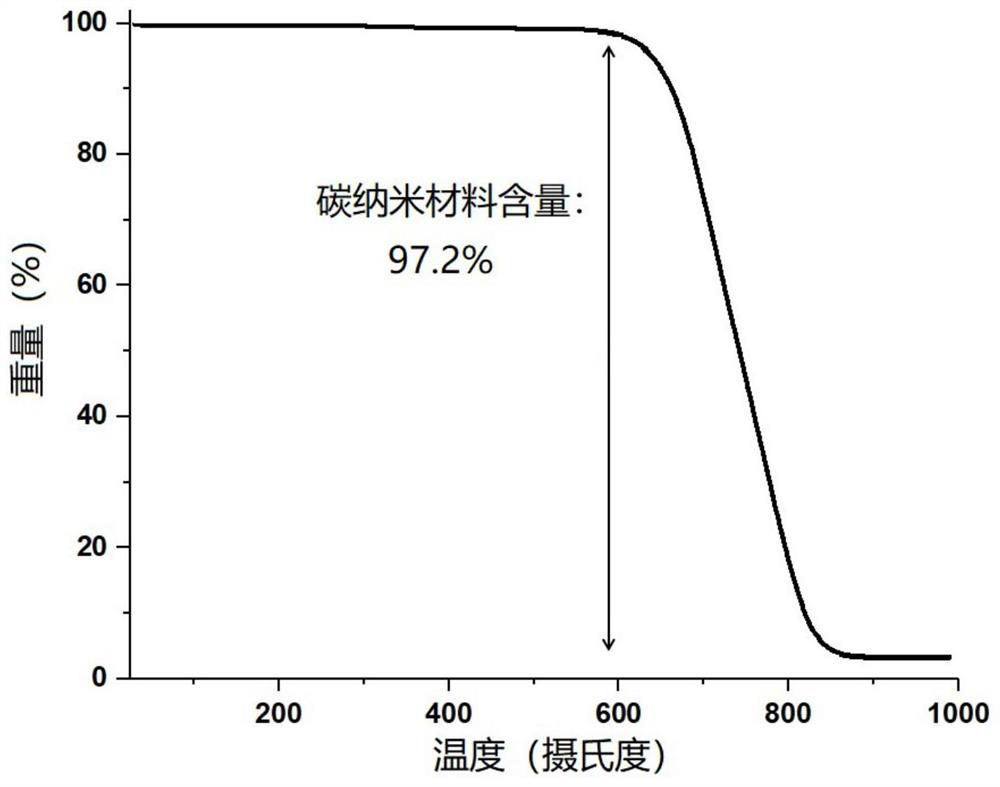

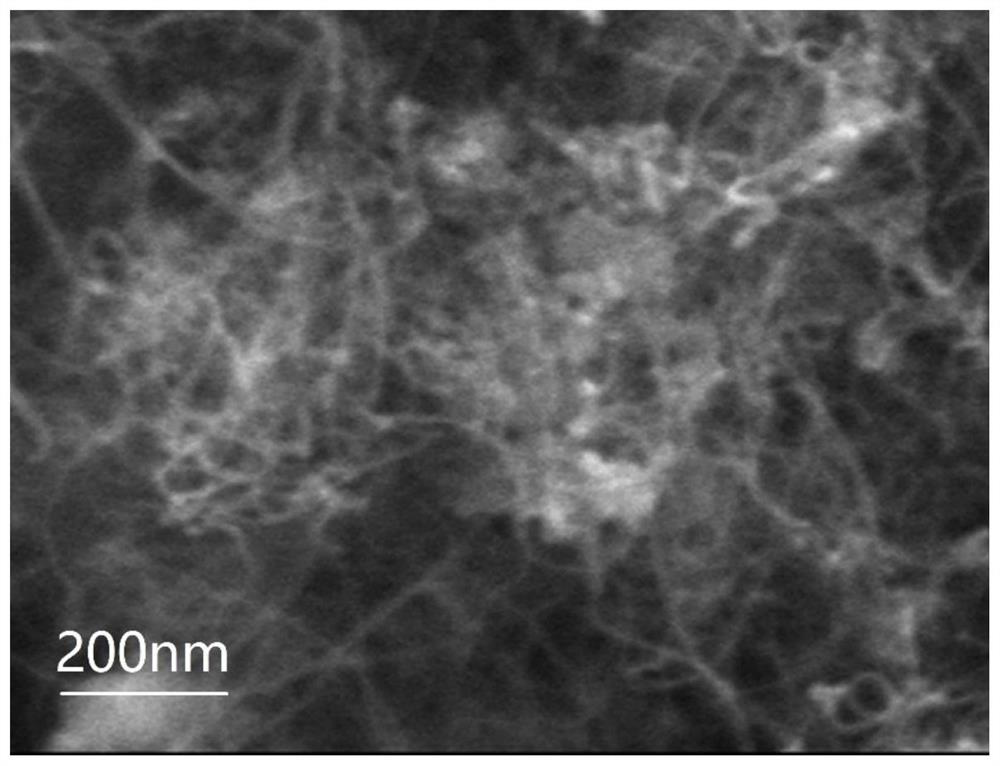

[0175] Preparation of multi-walled carbon nanotubes by catalytic carbonization of polyethylene plastics with carbon black (Super P)-supported iron-based catalysts:

[0176] In this example, carbon black (Super P) is used as a carrier, and metal iron is loaded on carbon black by impregnation method. The loading amount of iron is 50%, and the mass ratio of iron and carbon in the finally obtained catalyst powder is 1:1. .

[0177] In this embodiment, polyethylene is used as a raw material to prepare carbon nanotubes, and a composite carbon nanomaterial of carbon nanotubes and carbon black is prepared through five-stage microwave treatment. The schematic diagram of the process flow of this embodiment is as follows figure 1 As shown, the specific method is as follows:

[0178] (1) Fully mix carbon black (Super P) and iron precursor in distilled water according to the required ratio; calcinate at 350 degrees Celsius for 3 hours under an inert atmosphere of argon; The catalyst is s...

Embodiment 2

[0186] In this embodiment, carbon black (Super P) is used as a carrier, and metallic nickel is carried on the carbon black by impregnation.

[0187] In this embodiment, polyethylene is used as a raw material to prepare carbon nanotubes, and the specific method is as follows:

[0188] (1) Dissolve 49.55g of nickel nitrate in water, then disperse 10g of carbon black (Super P) in the nickel nitrate solution by stirring to form a suspension. After drying, it was calcined at 350 degrees Celsius for 3 hours under an inert atmosphere; after the calcination was completed, the sample was subjected to reduction treatment in a 5% H2 / Ar environment, and the reduction treatment condition was 650 degrees Celsius for 6 hours, and finally collected Black powder of nickel catalyst.

[0189] (2) The first stage of microwave treatment: the 19.89g nickel-carbon black catalyst and 20g polyethylene collected are put into a microwave reactor after being physically and mechanically mixed, and after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com