Nylon 12 hot melt adhesive and preparation method thereof

A hot melt adhesive, nylon technology, applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of decreased cohesive strength, decreased bonding effect, decreased construction efficiency, etc., to reduce residual orders. content, improving crystallization performance and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

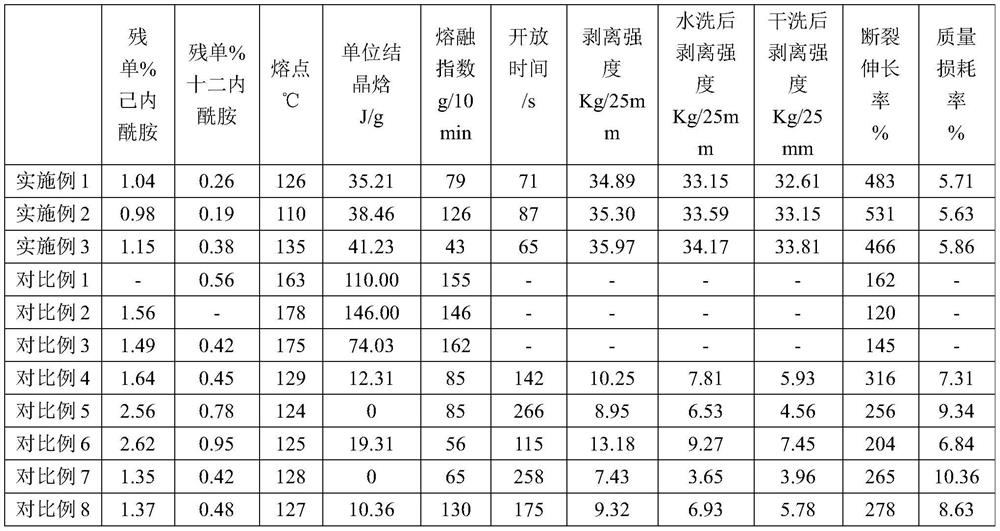

Examples

Embodiment 1

[0089] (1) 1799.12g (19.98mol) ethylenediamine, 1200.88g (19.98mol) oxalic acid, 1.5g sodium hypophosphite, 2.50g antioxidant 1098, 5.00g antioxidant 168, 180.15g acetic acid, 600g After pure water is added to the high-pressure reactor, start stirring at 100rpm, turn on heating to make the material slowly warm up to 50°C and react for 45 minutes, then continue to heat up to 180°C, keep heat and pressure for 90 minutes, and release the pressure to normal pressure through the pressure relief valve, and then After continuing to raise the temperature to 290°C for 40 minutes, the material was discharged and pelletized to prepare PA22. The average molecular weight was measured to be 1000, and it was dried for later use.

[0090] (2) 1750.00g caprolactam, 2250.00g laurolactam, 836.68g (5.73mol) adipic acid, 665.27g (5.73mol) hexamethylenediamine, 28.37g (0.27mol) diethylenetriamine, 63.33g (0.27mol) mol) dodecanedioic acid, 41.95g stearic acid, 1.40g sodium hypophosphite, 4.66g antio...

Embodiment 2

[0093] (1) 1559.24g (17.32mol) ethylenediamine, 1040.76g (17.32mol) oxalic acid, 0.26g sodium hypophosphite, 2.60g antioxidant 1098, 5.20g antioxidant 168, 260.00g acetic acid, 208.00g After pure water is added to the high-pressure reactor, start stirring at 100rpm, turn on heating so that the material is slowly heated to 40°C and react for 60 minutes, continue to heat up to 160°C, keep heat and pressure for 90 minutes, and release the pressure to normal pressure through the pressure relief valve, and then Continue to heat up to 280°C and react for 60 minutes, discharge and pelletize to prepare PA22, the average molecular weight is measured to be 600, and dry for later use.

[0094] (2) 1300.00g caprolactam, 3000.00g laurolactam, 716.52g (2.77mol) tetradecanedioic acid, 483.48g (2.77mol) decanediamine, 27.32g (0.27mol) triethylamine, 39.46g ( 0.27mol) of adipic acid, 12.86g of acetic acid, 0.56g of sodium hypophosphite, 1.86g of antioxidant 1098, 3.72g of antioxidant 168, and ...

Embodiment 3

[0097](1) 1401.03g (23.31mol) oxalic acid, 2098.97g (23.31mol) ethylenediamine, 0.35g sodium hypophosphite, 5.83g antioxidant 1098, 11.70g antioxidant 168, 284.95g benzoic acid, After adding 1050.00g of pure water into the high-pressure reactor, turn on stirring at 100rpm, turn on the heating to make the material slowly rise to 60°C and react for 30 minutes, then continue to heat up to 200°C, keep the heat and pressure for 120 minutes, and release the pressure to normal pressure through the pressure relief valve , and then continue to heat up to 290 ° C for 30 minutes, and then discharge and pelletize to prepare PA22. The average molecular weight is 1500, and it is dried for later use.

[0098] (2) 2300.00g caprolactam, 1650.00g laurolactam, 387.75g (2.22mol) decanediamine, 512.24g (2.22mol) dodecanedioic acid, 218.17g (2.13mol) pentamethylenediamine, 431.83g ( 2.14mol) sebacic acid, 53.36g (0.53mol) triethylamine, 106.64g (0.53mol) sebacic acid, 46.08g benzoic acid, 2.83g sod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grafting rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com