Photosensitive resin and photoresist composition using same

A photosensitive resin and photoresist technology, applied in the photoresist field, can solve the problem of increasing the difficulty of photoresist formulation, and achieve the effects of well controlling the photoacid diffusion performance, reducing the leaching rate and improving the resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

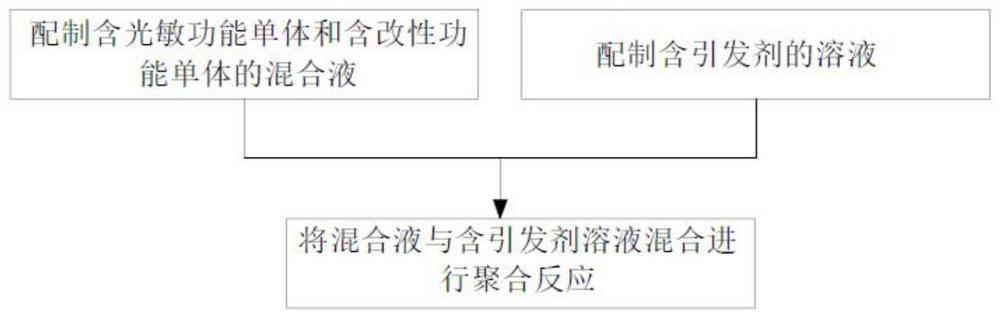

[0086] On the other hand, based on the above-mentioned photosensitive resin, the embodiment of the present invention also provides a preparation method of the above-mentioned photosensitive resin. The preparation method technological process of this photosensitive resin is as follows figure 1 As shown, it includes the following steps:

[0087] S01: Prepare a mixed solution containing photosensitive functional monomers and modified functional monomers,

[0088] Specifically, dissolving monomers containing modified functional units and monomers containing photosensitive functional units in the first solvent to obtain a mixed solution containing photosensitive resin monomers;

[0089] S02: prepare initiator solution,

[0090] Specifically, the initiator is dissolved in a second solvent to obtain an initiator solution;

[0091] S03: Mix the mixed solution with the initiator solution to carry out the polymerization reaction,

[0092] Specifically, the above-mentioned initiator ...

Embodiment 1-1

[0129] This embodiment provides a kind of preparation method of photosensitive resin, and reaction formula is as follows:

[0130]

[0131] The steps of photosensitive resin preparation method are as follows:

[0132] (1) Put 20g of monomer A and 20g of monomer B into a reactor filled with nitrogen, add 60g of the first ethyl acetate into the reactor, stir evenly, raise the temperature of the reactor to 77°C, and then add Add a mixture of 10 g of the second ethyl acetate and 4 g of benzoyl peroxide dropwise for 10 minutes, react at 77° C. for 7 hours, stop the reaction, and cool the reaction kettle to room temperature;

[0133] (2) Add 600g of the first methanol to the reaction kettle cooled to room temperature in step (1), and after 1 hour of precipitation, export the liquid in the reaction kettle, then add 70g of the third ethyl acetate to the reaction kettle until the precipitation dissolves;

[0134](3) add 600g second methanol in the reactor of step (2), repeat the op...

Embodiment 1-2

[0136] This embodiment provides a kind of preparation method of photosensitive resin, and reaction formula is as follows:

[0137]

[0138] The steps of the preparation method of the photosensitive resin are as follows:

[0139] (1) Add 10g of monomer A, 20g of monomer B, and 10g of monomer C into a reactor filled with nitrogen, add 60g of the first ethyl acetate into the reactor, and stir the reactor to 77 ℃, then drop the mixed solution of the second ethyl acetate 10g and 4g benzoyl peroxide in the described reaction kettle, the time of dropping is 10min, react at 77 ℃ for 7 hours, stop the reaction, the temperature of the described reaction kettle Cool to room temperature;

[0140] (2) Add 600g of the first methyl alcohol to the reaction kettle cooled to room temperature in step (1), after 1h of precipitation, derive the liquid in the described reaction kettle, then add the 3rd ethyl acetate of 70g in the described reaction kettle until the precipitate dissolves;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com