Method for producing androstane dienedione through fermentation of arthrobacter simplex

A technology of androstadiene dione and Arthrobacter simplex is applied in the optimization field of substrate pretreatment, which can solve the problems of low transformation efficiency, high cost, low recovery rate and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

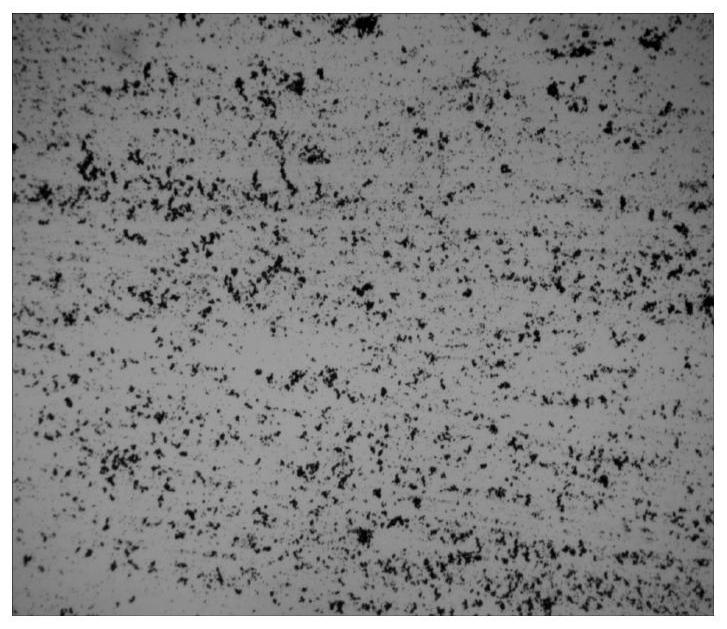

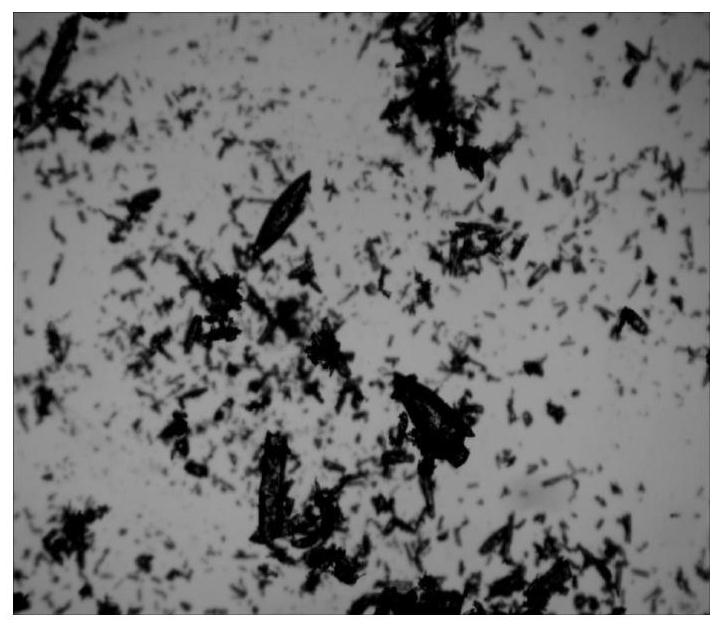

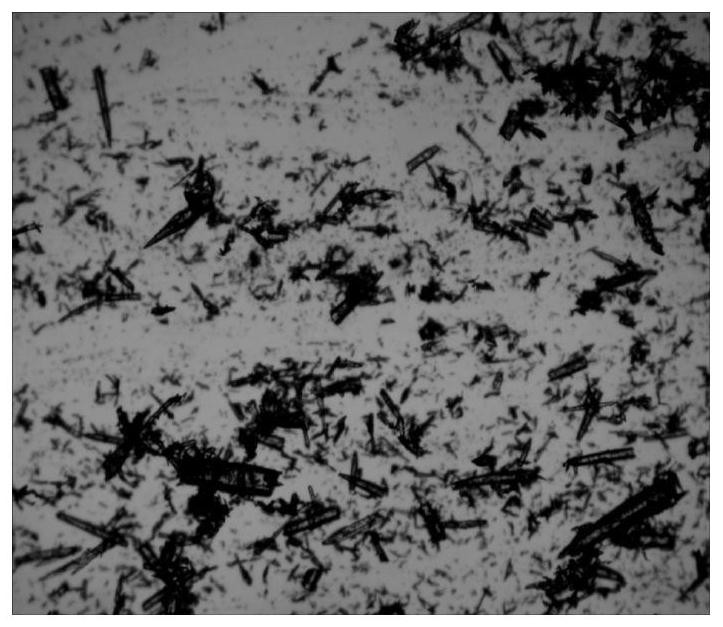

Image

Examples

Embodiment 1

[0034] Fermentation medium components: glucose: 10g / L, peptone: 3g / L, corn steep liquor: 10g / L, potassium dihydrogen phosphate: 1g / L, yeast extract: 1g / L, manganese chloride: 0.003g / L, sulfuric acid Ferrous iron 0.03g / L, Tween 0.04g / L, foam enemy 0.04g / L, initial pH of fermentation = 7.0, substrate is water analysis pretreatment AD substrate.

[0035] The fermentation process is as follows: first-level seed cultivation, adding culture medium in a jacketed 50L fermenter with a filling coefficient of 0.6, sterilizing, cooling to 33°C, inserting Arthrobacter simplex, inoculum size 10%, fermentation in two Stage: ① Cell growth stage: after inoculation, adjust the air flow to 3.0m 3 / h, the stirring rate is 200r / min, the temperature is controlled at 33°C, cultured for 9h, the bacterial concentration is monitored at 20%, and feeding is carried out. ② Microbial transformation stage: feed concentration 10g / L, adjust air flow rate 1.0m 3 / h, the stirring rate is 300r / min, the tempera...

Embodiment 2

[0038] Fermentation medium components: glucose: 10g / L, peptone: 3g / L, corn steep liquor: 10g / L, potassium dihydrogen phosphate: 1g / L, yeast extract: 1g / L, manganese chloride: 0.003g / L, sulfuric acid Ferrous iron 0.03g / L, Tween 0.04g / L, foam enemy 0.04g / L, initial pH of fermentation = 7.0, substrate is water analysis pretreatment AD substrate.

[0039] The fermentation process is as follows: first-level seed cultivation, adding culture medium in a jacketed 50L fermenter with a filling coefficient of 0.6, sterilizing, cooling to 33°C, inserting Arthrobacter simplex, inoculum size 10%, fermentation in two Stage: ① Cell growth stage: after inoculation, adjust the air flow to 3.0m 3 / h, the stirring rate is 200r / min, the temperature is controlled at 33°C, cultivated for 8h, and the bacterial concentration is monitored at 30%, before feeding. ② Microbial transformation stage: feed concentration 10g / L, adjust air flow rate 1.0m 3 / h, the stirring rate is 300r / min, the temperature i...

Embodiment 3

[0042] Fermentation medium components: glucose: 30g / L, soybean peptone: 5g / L, corn steep liquor: 30g / L, potassium dihydrogen phosphate: 5g / L, yeast extract: 4g / L, manganese chloride: 0.003g / L, Ferrous sulfate 0.03g / L, Tween 0.12g / L, foam enemy 0.2g / L, initial pH of fermentation = 7.0, substrate is water analysis pretreatment AD substrate.

[0043] The fermentation process is as follows: first-level seed cultivation, adding culture medium in a jacketed 50L fermenter with a filling coefficient of 0.6, sterilizing, cooling to 33°C, inserting Arthrobacter simplex, inoculum size 10%, fermentation in two Stage: ① Cell growth stage: after inoculation, adjust the air flow rate to 4.0m 3 / h, the stirring rate is 300r / min, the temperature is controlled at 33°C, cultivated for 7h, and the bacterial concentration is monitored at 40%, before feeding. ② Microbial transformation stage: feed concentration 10g / L, adjust air flow rate 2.0m 3 / h, the stirring rate is 400r / min, the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com