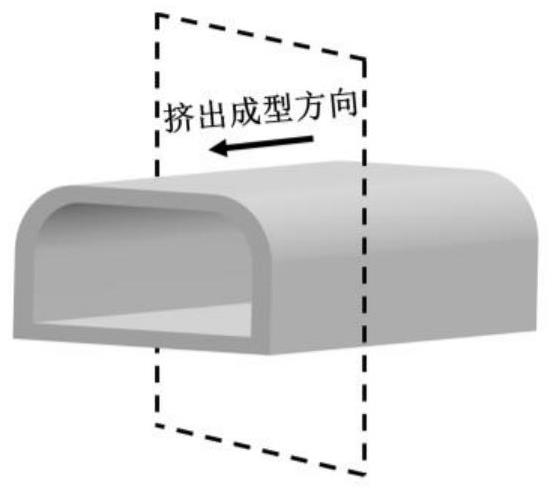

Long and short glass fiber hybrid reinforced polypropylene base station antenna outer cover composite material and preparation method thereof

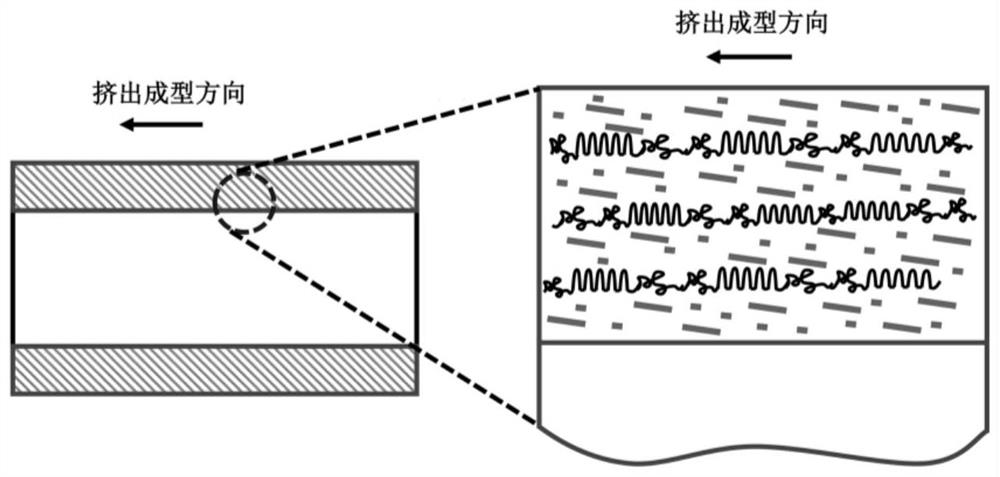

A polypropylene base station, long glass fiber technology, applied in the direction of the radiation unit cover, etc., can solve the problem of being unsuitable for extrusion molding process, and achieve the effect of low dielectric constant, high dielectric loss tangent, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

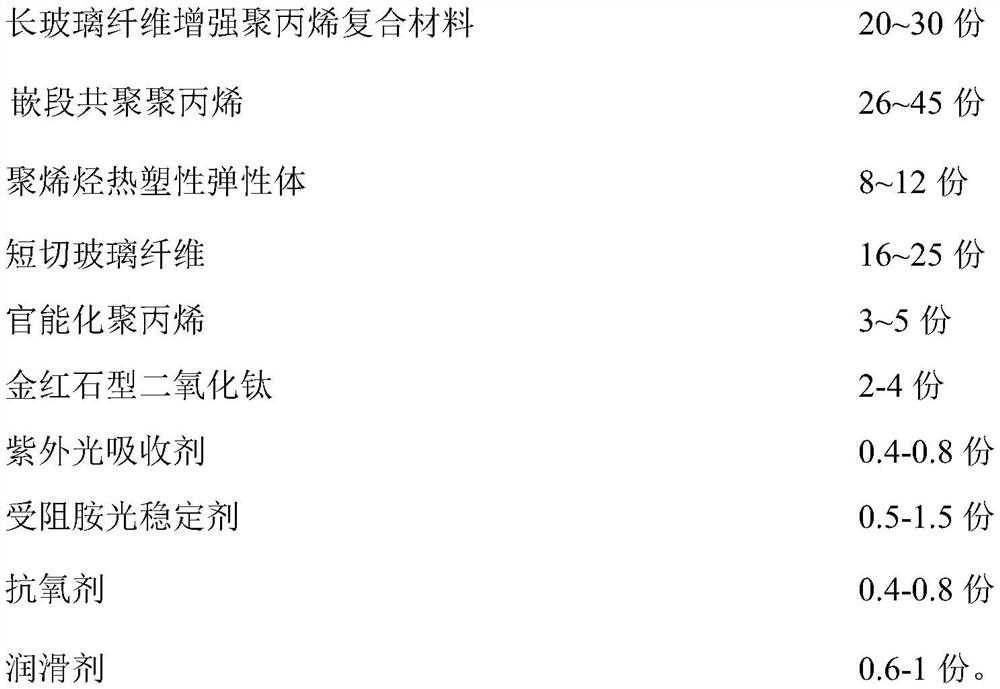

[0035] Raw material formula (mass ratio, parts): low dielectric properties long glass fiber reinforced polypropylene (fiber content 70%) 20, block copolymerized polypropylene resin (load 2.16kg, MFR=0.4g / 10min at a temperature of 230°C) 45 , polyolefin thermoplastic elastomer (octene content 55%, load 2.16kg, temperature 190°C when MFR=0.2g / 10min) 10, functionalized polypropylene (maleic anhydride content 1.0%, load 2.16kg, temperature 230°C MFR=5g / 10min)3, low dielectric properties chopped glass fiber 16, rutile titanium dioxide 3, ultraviolet light absorber UV 326 0.6, hindered amine light stabilizer C944 1.0, antioxidant B215 0.6, zinc stearate 0.3 , Interacid amide 0.2, ethylene bis stearic acid amide 0.3.

[0036] Preparation Process:

[0037] Mixing and granulation of functionalized polypropylene and antioxidant: First, mix functionalized polypropylene and antioxidant B215 uniformly in a high-speed mixer at room temperature according to the formula, and then blend in a ...

Embodiment 2

[0042] Raw material formula (mass ratio, parts): low dielectric properties long glass fiber reinforced polypropylene (fiber content 70%) 20, block copolymerized polypropylene resin (load 2.16kg, MFR=0.3g / 10min at 230°C) 42 , polyolefin thermoplastic elastomer (octene content 60%, load 2.16kg, temperature 190 ℃ MFR = 0.5g / 10min) 10, functionalized polypropylene (maleic anhydride content 0.8%, load 2.16kg, temperature 230 ℃ MFR=10g / 10min)3, low dielectric properties chopped glass fiber 19, rutile titanium dioxide 3, ultraviolet light absorber UV 326 0.6, hindered amine light stabilizer C944 1.0, antioxidant B215 0.6, zinc stearate 0.8 .

[0043] Preparation Process:

[0044] Mixing and granulation of functionalized polypropylene and antioxidant: First, mix functionalized polypropylene and antioxidant B215 uniformly in a high-speed mixer at room temperature according to the formula, and then blend in a twin-screw extruder at 170-200°C The pelletizer yields functionalized polypr...

Embodiment 3

[0049] Raw material formula (mass ratio, parts): low dielectric properties long glass fiber reinforced polypropylene (fiber content 60%) 30, block copolymer polypropylene resin (load 2.16kg, MFR=0.5g / 10min at a temperature of 230°C) 35 , polyolefin thermoplastic elastomer (octene content 60%, load 2.16kg, temperature 190°C MFR = 1.0g / 10min) 8, functionalized polypropylene (maleic anhydride content 0.5%, load 2.16kg, temperature 230°C MFR=8g / 10min)4, low dielectric properties chopped glass fiber 17, rutile titanium dioxide 3, ultraviolet light absorber UV 326 0.6, hindered amine light stabilizer C944 1.0, antioxidant B215 0.6, zinc stearate 0.3 , Interacid amide 0.5.

[0050] Preparation Process:

[0051] Mixing and granulation of functionalized polypropylene and antioxidant: First, mix functionalized polypropylene and antioxidant B215 uniformly in a high-speed mixer at room temperature according to the formula, and then blend in a twin-screw extruder at 170-200°C The pelleti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com