High-conductivity corrosion-resistant polymer composite coating, preparation method thereof and bipolar plate

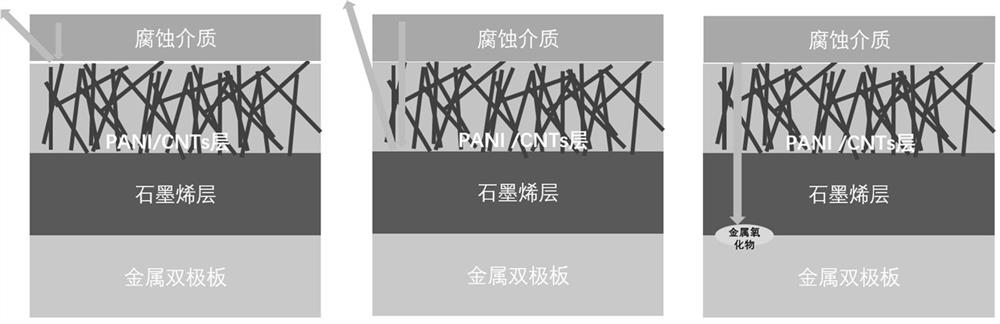

A composite coating and polymer technology, applied in the fields of materials science and electrochemistry, can solve problems such as structural defects, galvanic corrosion of graphene and metal substrates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Specifically, the preparation method of the highly conductive and corrosion-resistant polymer composite coating of the present application comprises the following steps:

[0037] (1) Depositing a graphene oxide coating on the surface of the metal substrate:

[0038] Step 11): adding graphene oxide in deionized water, dispersing, and preparing graphene oxide suspension;

[0039] Step 12): Using a three-electrode system, the metal substrate is used as the working electrode, the saturated calomel electrode is used as the reference electrode, and the platinum electrode is used as the auxiliary electrode, and the graphene oxide suspension prepared in step 11) is used as the electrolyte. The graphene oxide coating is deposited on the surface of the metal substrate by a chemical method to obtain the metal substrate with the graphene oxide coating.

[0040] In step 11), the way of dispersion treatment may be one or both of ultrasonic dispersion or stirring dispersion. The met...

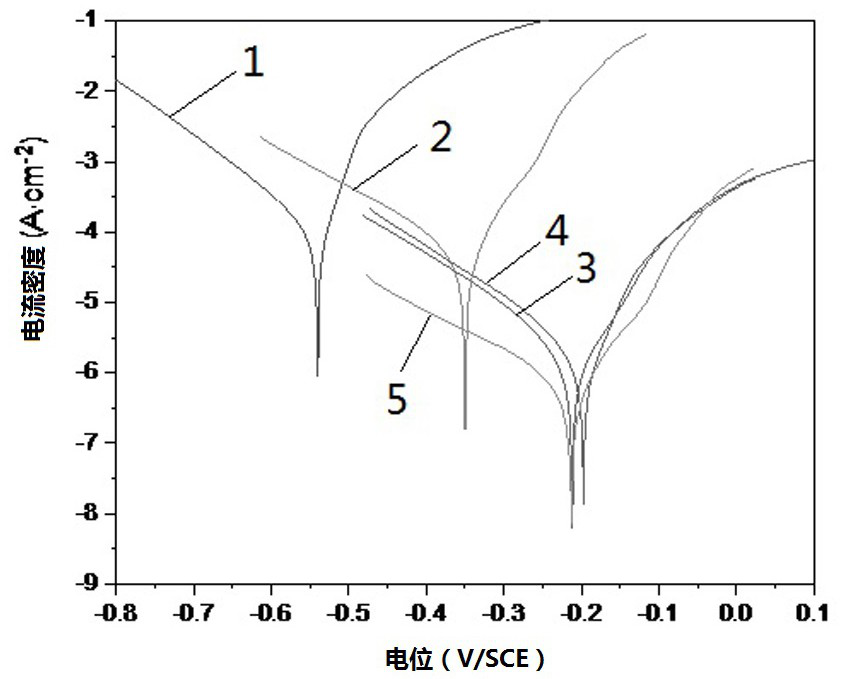

Embodiment 1

[0083] A 1.0mg / L graphene oxide suspension was prepared with deionized water and graphene oxide, and used as the electrolyte for electrochemical deposition. A three-electrode system was used, with the treated aluminum alloy substrate as the working electrode, saturated glycerin The mercury electrode is used as the reference electrode, and the platinum electrode is used as the auxiliary electrode. The deposition method adopts conventional pulse voltammetry (NPV), the voltage range is 0-10V, the pulse width is 0.1s, the step width is 10mV, and the step width is 0.5s. A graphene oxide coating with a thickness of about 100 nm was obtained.

[0084] Use deionized water and functionalized carbon nanotubes to configure the suspension of 3mg / L functionalized carbon nanotubes, then add aniline monomer, so that the concentration of aniline monomer in the PANI / CNTs suspension is 0.01M, with PANI / CNTs The suspension is used as the electrolyte, and the pH value is adjusted between 3-5. A t...

Embodiment 2

[0087] Prepare 1.0 mg / L graphene oxide suspension with deionized water and graphene oxide, and use this as electrolyte for electrochemical deposition. A three-electrode system is used, with the treated aluminum alloy substrate as the working electrode, saturated glycerol The mercury electrode is used as the reference electrode, and the platinum electrode is used as the auxiliary electrode. The deposition method adopts cyclic voltammetry, the control scanning range is -1500~600mV / SCE, the scanning speed is 10mV / s, and the number of cycles is 10 times. The prepared thickness is about 100nm graphene oxide coating.

[0088] Use deionized water and functionalized carbon nanotubes to configure the suspension of 3mg / L functionalized carbon nanotubes, then add aniline monomer, so that the concentration of aniline monomer in the PANI / CNTs suspension is 0.01M, with PANI / CNTs The suspension is used as the electrolyte, and the pH value is adjusted between 3-5. A three-electrode system is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com