Carbon fiber-based electrochemical compound, molecular imprinting sensor as well as preparation method and application of molecular imprinting sensor

An electrochemical and carbon fiber-based technology, applied in the field of carbon fiber-based electrochemical composites, molecular imprinted sensors and their preparation, to achieve good chemical stability, high electron transfer rate, and large aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The carbon fibers were ultrasonically cleaned with acetone, secondary water, and absolute ethanol for 25 minutes, and then dried in a vacuum oven at 50°C.

[0050] Take 0.216g CuSO 4 ·5H 2 Dissolve O in 80mL deionized water, stir for 15min; add 0.84mL 25% ammonia water, stir for 15min; then add 0.384g NaOH, stir for 15min until completely dissolved; then add 0.25mL ammonia water and 1.14g hexadecyltrimethyl ammonium chloride, continue to stir for 30 minutes to make it completely dissolved; pour the above solution into a 100mL hydrothermal reaction kettle, then add the treated carbon fiber, and react in an oven at 180°C for 12 hours. After the reaction, the sample is cooled to room temperature Take it out and dry it in an oven at 60°C for use; put the sample obtained above in a muffle furnace and bake it at 450°C for 4 hours, and the product obtained is the electrochemical composite (Cu(OH) 2 / CF).

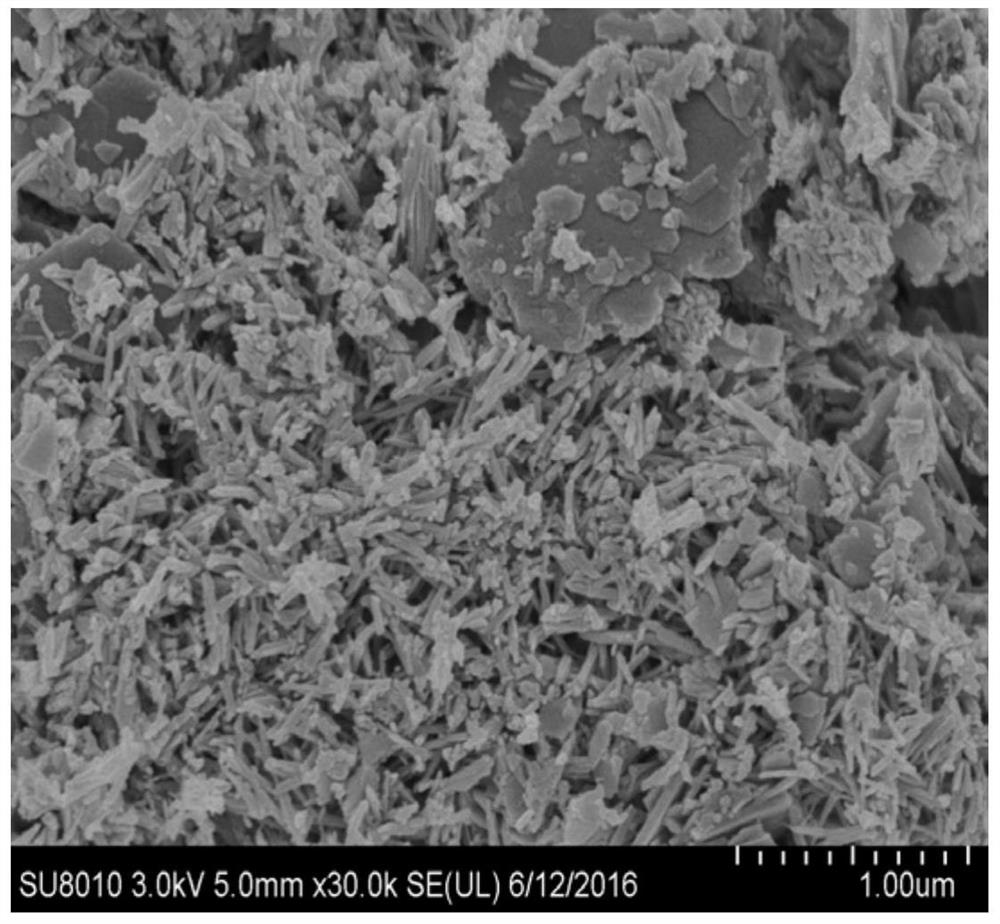

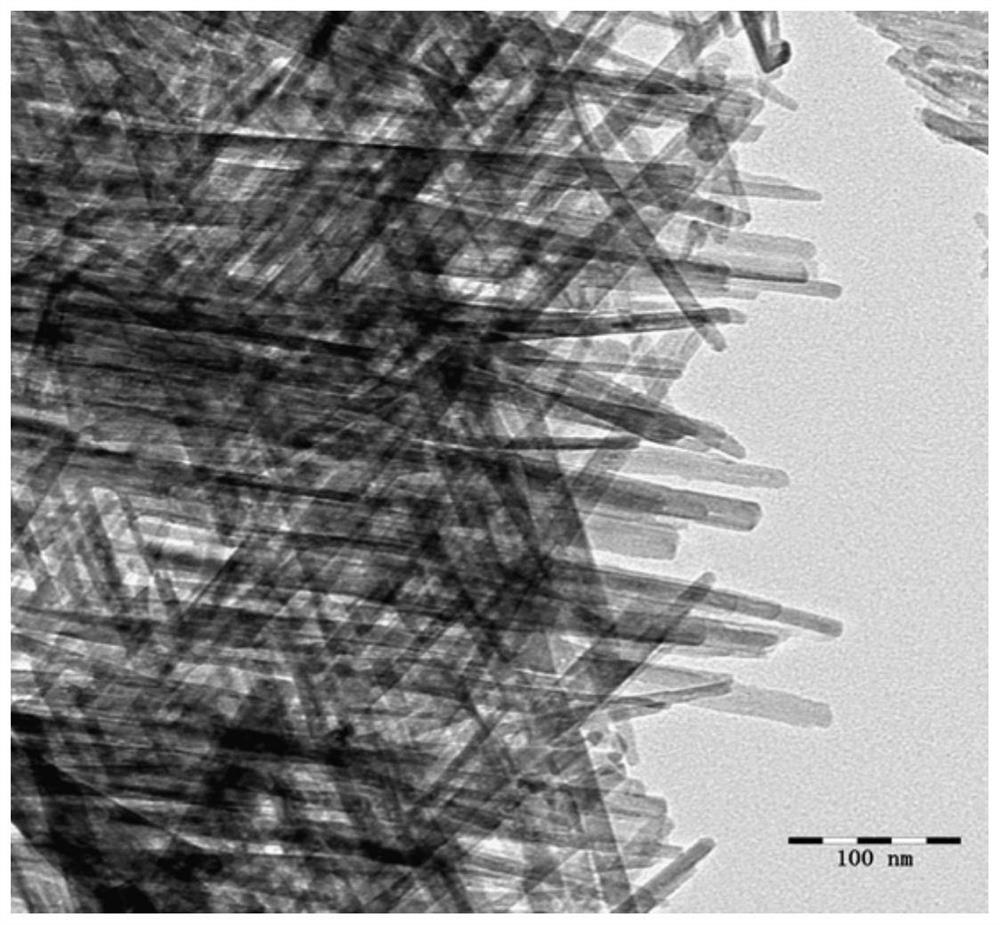

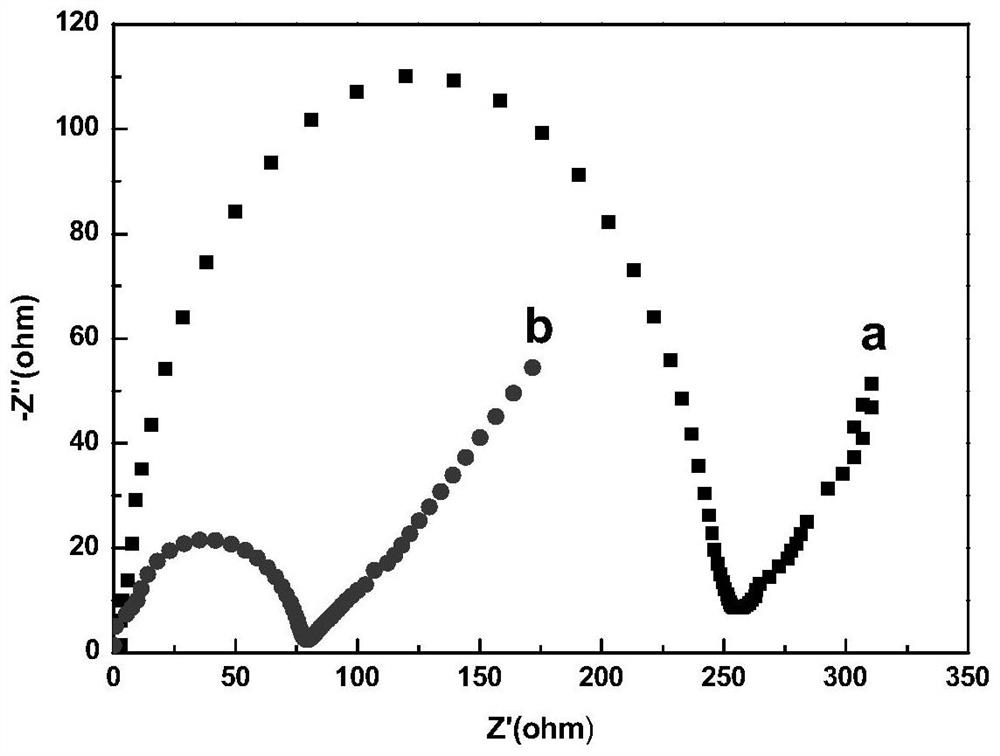

[0051] Electrochemical composite (Cu(OH) 2 / CF) SEM and TEM images ...

Embodiment 2

[0053] The electrochemical compound prepared in the example was taken, and it was first dispersed by magnetic stirring for 30 minutes, and then dispersed by ultrasonic wave for 20 minutes to obtain a modification solution with a concentration of 0.1M. Take a glassy carbon electrode, polish it, take 0.1 μL of modification solution with a micro-sampler, drop it on the polished glassy carbon electrode, and then dry it under an infrared lamp to obtain a modified electrode.

[0054] Carried out under nitrogen atmosphere. Prepare PBS buffer solution (0.1mol / L) with pH=6; configure 50mL electrolyte solution with 0.5mol / L NaCl, add 3mol / L o-phenylenediamine to the electrolyte solution until completely dissolved, take 0.02g theophylline , sonicated in 20 mL of methanol.

[0055] Take the electrolytic cell and place it on a magnetic stirrer to stir, and quickly pass the N 2 15min; Add 30mL of PBS buffer solution to the electrolytic cell, stir rapidly and pass through the N 2 Remove ...

Embodiment 3

[0059] The molecularly imprinted sensor prepared in Example 2 was used in a three-electrode system to detect different concentrations of theophylline:

[0060] During the detection process, 13 kinds of theophylline solutions with different concentrations were used as the electrolyte, and the glassy carbon electrode modified by molecularly imprinted membrane was used as the working electrode to form a three-electrode system with the calomel electrode and the platinum sheet electrode. The DPV curve of the electrolyte is drawn, and the "peak current value" and the "theophylline concentration value" of the solution are drawn as the ordinate and abscissa respectively to obtain the standard curve of theophylline concentration. Scanning results such as Figure 4 , Figure 5 shown.

[0061] Depend on Figure 4 , Figure 5 It can be seen that the DPV curve and the fitted C-I standard curve of the system under different theophylline contents indicate that when the concentration of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com