Walnut oil microcapsule and preparation method thereof

A technology of walnut oil and microcapsules, applied in the field of walnut oil microcapsules and its preparation, to achieve the effects of enhancing stability, delaying oxidative deterioration, and high embedding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

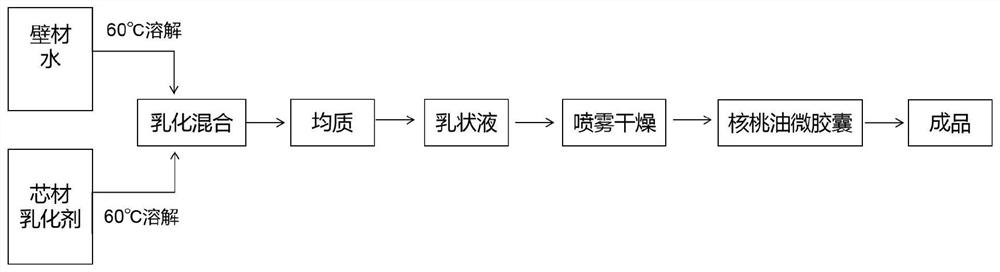

Method used

Image

Examples

Embodiment 1

[0057] Degreased walnut meal

[0058] The walnut meal was dried at 55°C to a constant weight, and then crushed to 100 mesh with a traditional Chinese medicine grinder. The walnut meal was degreased with n-hexane under constant magnetic stirring (the ratio of walnut meal / n-hexane was 1:10w / v) for 1.5h. The solution was filtered through filter paper under reduced pressure, and the filter residue was degreased repeatedly with n-hexane until the filtrate was clear. The filter residue was air-dried in a fume hood and ground to obtain defatted walnut meal powder (DFWF), which was stored at -18°C. The protein content in DFWF was 57.05%. , 2.54% fat, 2.61% ash, and 9.05% moisture.

[0059] Extraction of WNPI

[0060] Dissolve DFWF in distilled water adjusted to pH 11 with 1M NaOH (the ratio of solid to liquid is 1:20w / v), stir with a magnetic stirrer for 2 hours, and then centrifuge the solution at 4°C (4500rpm, 30min) , the precipitate was redissolved in distilled water with a pH v...

Embodiment 2

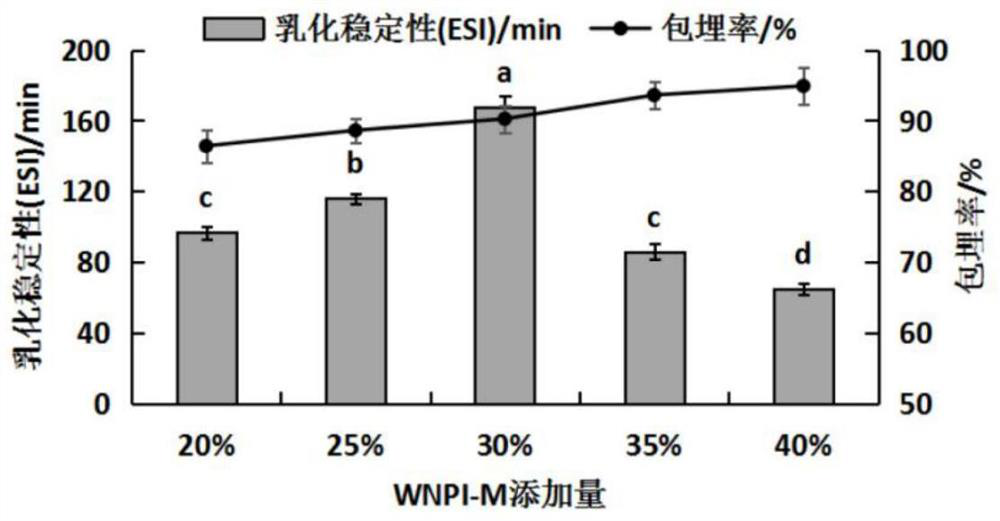

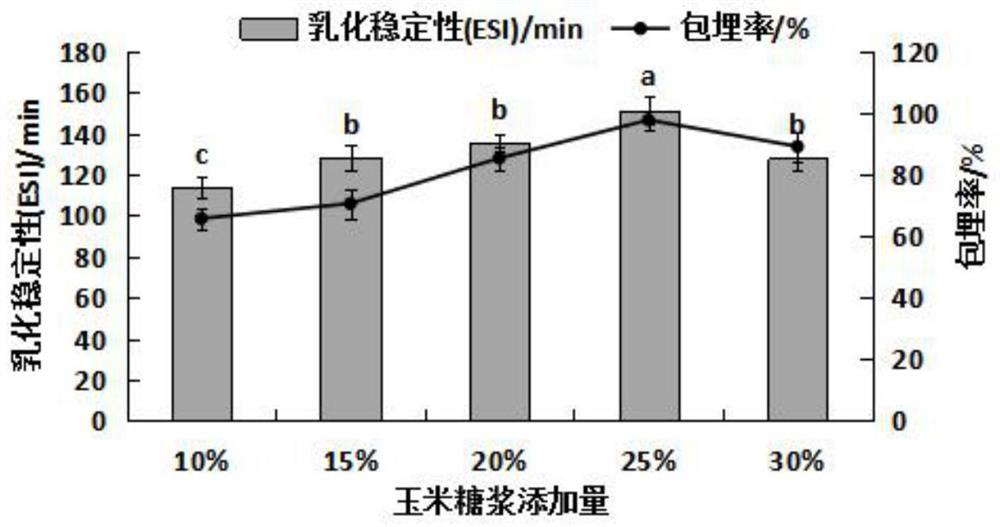

[0105] According to the optimal process parameters: WNPI-M addition 26.46%, corn syrup addition 21%, walnut oil 30%, spray drying inlet air temperature 175 ℃, prepared WNPI-M walnut oil microcapsules. The modified whey protein and WNPI of the same quality were used instead of WNPI-M as a control, and the modified whey protein was prepared by referring to the existing method, which was prepared by glycosylation reaction of whey protein and xylose at a ratio of 2:1.

[0106] Determination of Physical and Chemical Indexes of Walnut Oil Microcapsules

[0107] (1) Determination of surface oil content: Accurately weigh a certain mass of walnut oil microcapsule samples in a dry beaker, add petroleum ether to extract the oil on the surface of the microcapsules (w / v 1:10), and gently stir the petroleum ether through a pump filter device into a constant weight round bottom flask. The petroleum ether was evaporated to dryness using a rotary evaporator and dried in an oven at 60°C until ...

Embodiment 3

[0128] The determination of the conditions of embodiment 3 walnut protein glycosylation reaction

[0129] Mix WNPI with sugar (glucose, maltose, lactose, maltodextrin, dextran (40KDa)) in different ratios (sugar to protein ratio 3:1, 2:1, 1:1, 1:2, 1:3 ), dissolved in distilled water, and prepared into a solution with a concentration of (5mg / mL, 10mg / mL, 15mg / mL, 20mg / mL, 25mg / mL, 30mg / mL), adjust the pH value of the system to 8.45-8.5, and keep the magnetic force constant Stir for 1 hour to fully mix and then place it at 4°C for 12 hours to fully hydrate it. Under sealed conditions, react in a water bath at 80°C for a certain period of time (0h, 2h, 4h, 6h, 8h, 10h), quickly cool down to room temperature to end the reaction, and then dialyze with distilled water at 4°C for 24h to remove unreacted sugar. The glycosylated product of WNPI was obtained by freeze-drying.

[0130] Grafting degree of different sugar species and WNPI

[0131] The molecular weight of sugar and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com