Preparation method and application of treating agent based on municipal sludge biochar

A technology of municipal sludge and biochar, applied in the field of functional materials and environmental water treatment, can solve the problems of complex catalyst preparation, difficult treatment of fouling membrane, secondary pollution, etc., and achieve resource utilization, superior adsorption performance, and pore structure. developed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

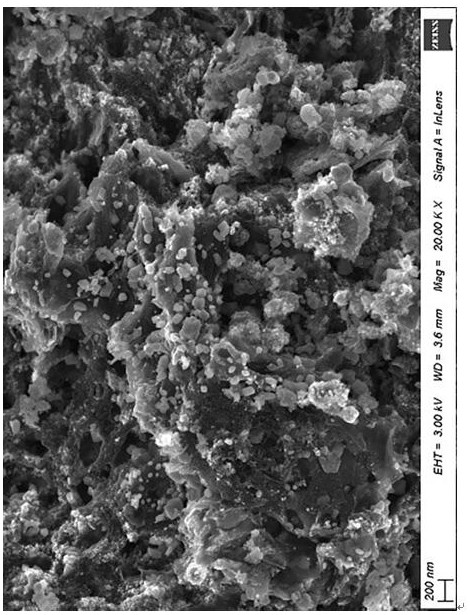

[0047] Example 1, a treatment agent based on municipal sludge biochar, including an adsorbent and a catalyst, the adsorbent is porous sludge biochar (PSDBC), the catalyst includes magnetic sludge biochar (MSDBC) and zero-valent iron-loaded sludge biological Charcoal (ZVI@PSDBC).

Embodiment 2

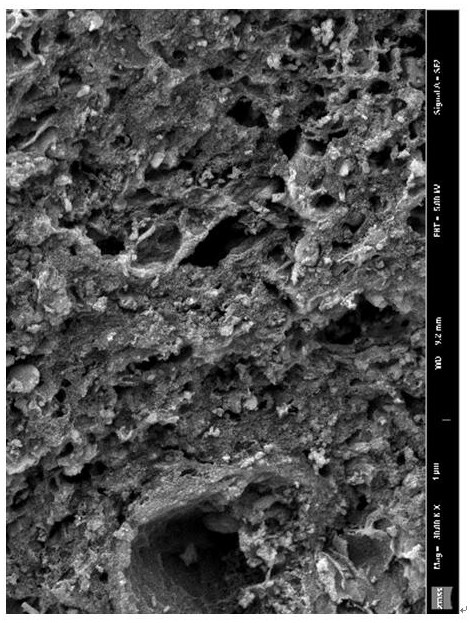

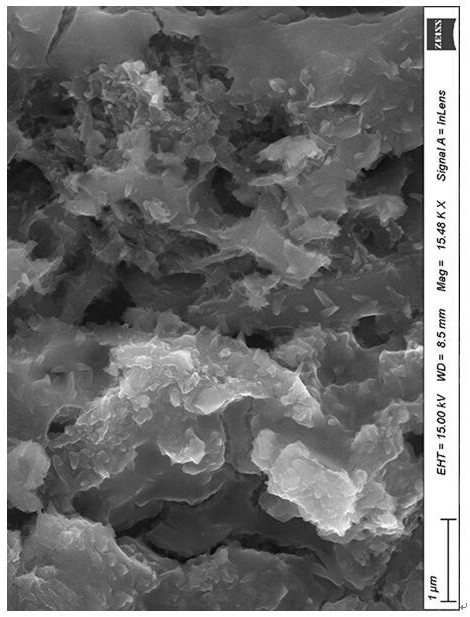

[0048] Embodiment 2, the preparation method of porous sludge biochar (PSDBC) described in the above embodiment 1, includes the following steps: after cleaning the municipal sludge, dry it in an oven at 105°C for 30h, and use a mortar or grinder to carry out After grinding, sieve through an 8-mesh sieve to obtain sludge particles; according to the capacity of the tubular muffle furnace, take an appropriate amount of sludge particles and place them in the tubular muffle furnace. The heating rate was pyrolyzed at 800°C for 2 hours. After the temperature of the tube furnace dropped to room temperature naturally, it was taken out, soaked in 1mol / L hydrochloric acid solution for 24 hours, washed with ethanol and deionized water until pH = 7, and dried in an oven at 80°C. and then dried to obtain PSDBC.

[0049] Adsorption experiment of PSDBC on the dye rhodamine B (RhB): Weigh 0.6, 0.8, 1.0g / L PSDBC (with an accuracy of 0.0001g) into a 250mL beaker, add 100mL of the solution to be t...

Embodiment 3

[0052] Embodiment 3, in the above-mentioned embodiment 1, the preparation method of the porous sludge biochar (PSDBC) includes the following steps: after cleaning the municipal sludge, dry it in an oven at 105°C for 30 hours, and use a mortar or grinder to After grinding, sieve through an 8-mesh sieve to obtain sludge particles; according to the capacity of the tubular muffle furnace, take an appropriate amount of sludge particles and place them in the tubular muffle furnace. The heating rate is pyrolyzed at different temperatures (500°C, 600°C, 700°C, 800°C) for 2 hours. After the temperature of the tube furnace naturally drops to room temperature, it is taken out, soaked in 1mol / L hydrochloric acid solution for 24 hours, and washed with ethanol Washing, washing with deionized water to pH = 7, and drying in an oven at 80°C to obtain PSDBC.

[0053] Adsorption effect of PSDBC prepared at different temperatures on RhB: Weigh 1.0 g / L of PSDBC prepared at different temperatures i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com