Preparation method of columnar active coke for desulfurization and denitrification

A technology for desulfurization, denitrification and active coke, which is applied in the field of active coke, can solve the problems that the quality index fails to meet the national standard, and the wear resistance of active coke is poor, so as to improve the wear resistance and compressive strength, and improve the wear resistance. Strength and compressive strength, the effect of enhancing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of columnar activated coke for desulfurization and denitrification of the present invention comprises the following steps:

[0037] S1, pretreatment, crushing raw materials to particle size D 99 ≤0.75mm, the raw material powder is obtained; the raw material is composed of semi-coke and petroleum coke green coke / coal-based pitch green coke;

[0038] The specific treatment process is: mix 70-85 parts by mass of semi-coke and 15-30 parts by mass of raw petroleum coke / coal-based pitch raw coke as raw materials, make powder, and grind until 99% of the particles pass through a 200-mesh sieve. (that is, the particle size is less than or equal to 0.75mm), and the raw material powder is obtained; wherein the volatile matter content in petroleum coke raw coke / coal-based pitch raw coke is 7-12wt%.

[0039] S2, kneading and molding, adding a binder and water to the raw material powder for kneading and molding to obtain an active coke precursor; the weight ra...

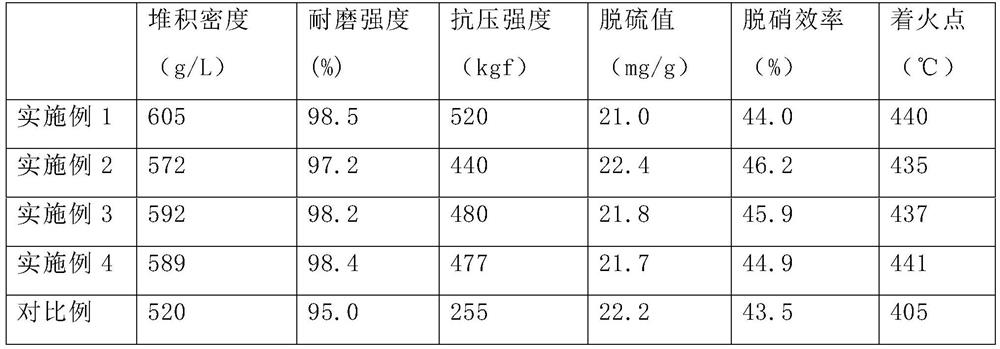

Embodiment 1

[0047] (1) Preparation of columnar activated coke for desulfurization and denitrification in this example

[0048] 70 parts by weight of semi-coke and 30 parts by weight of petroleum coke raw coke (7-12% volatile content) are mixed uniformly as raw materials, and then pulverized and ground until 99% of the particles pass through a 200-mesh sieve (that is, the particle size is less than or equal to 0.75mm), to obtain raw material powder. 90 parts by weight of high-temperature coal tar and 10 parts by weight of purified asphalt centrifuge slag (with quinoline insoluble content higher than 15%) are prepared as binders for use. Prepare the prepared raw material powder and binder according to the weight ratio of 70:30, add binder and water to the raw material powder, fully stir and knead at a temperature of 90°C, and send it into the mold after 45 minutes Processing in 35Mpa under the pressure of 35Mpa to obtain the active coke precursor with a particle size of Φ=9mm; the amount o...

Embodiment 2

[0052] (1) Preparation of columnar activated coke for desulfurization and denitrification in this example

[0053] 85 parts by weight of semi-coke and 15 parts by weight of petroleum coke raw coke (7-12% volatile content) are mixed uniformly as raw materials, and then pulverized and ground until 99% of the particles pass through a 200-mesh sieve (that is, the particle size is less than or equal to 0.75mm), to obtain raw material powder. 95 parts by weight of high-temperature coal tar and 5 parts by weight of purified asphalt centrifuge slag (with quinoline-insoluble content higher than 15%) are prepared as binders for future use. Prepare the prepared raw material powder and binder according to the weight ratio of 80:20, add binder and water to the raw material powder, fully stir and knead at a temperature of 90°C, and send it into the mold after 45 minutes Processing in 35Mpa under the pressure of 35Mpa to obtain the active coke precursor with a particle size of Φ=9mm, wherei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com