Power generation equipment and power generation method based on multi-dimensional assembled photothermal conversion phase change material

A technology of light-to-heat conversion and power generation equipment, applied in heat exchange materials, solar thermal power generation, mechanical equipment, etc., can solve the problem that the latent heat of the phase change core material cannot be fully released, the phase change material is not easy to package, and the heat storage and transfer method is single, etc. problems, to achieve the effects of high photothermal conversion efficiency, strong cycle stability, and high photothermal conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

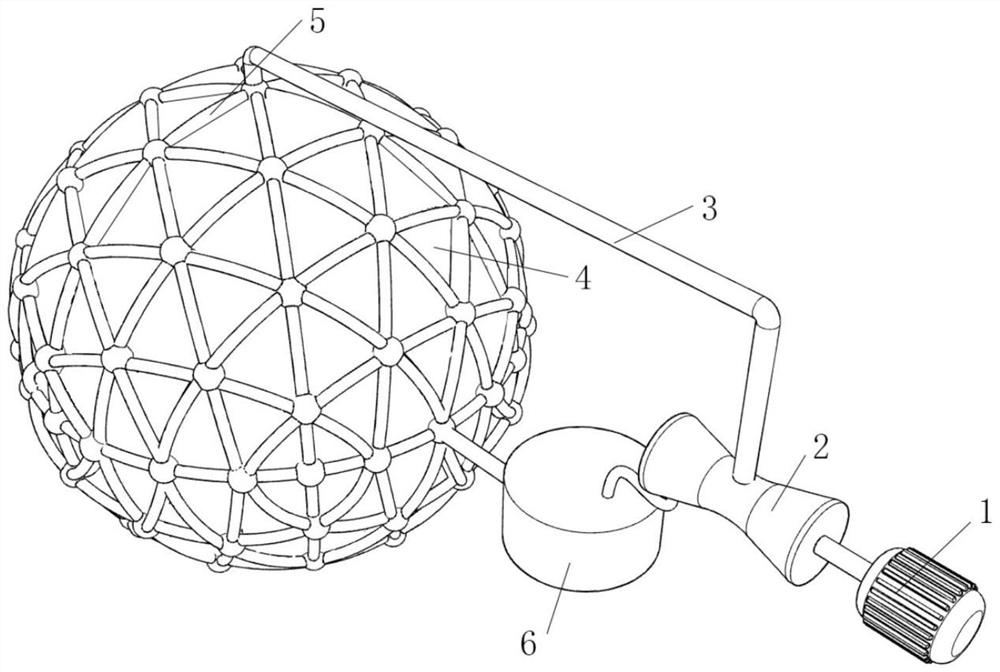

[0041] refer to Figure 1-2 , the present invention provides a power generation device based on multi-dimensional assembly of light-to-heat conversion phase change materials, including a generator 1, a steam turbine 2 is fixedly connected to the rotating shaft of the generator 1, and the top of the steam turbine 2 is fixedly connected to a steam communication pipe 3 one end of

[0042] Also includes: steam generating ball 4;

[0043] Fixed grid frame 5: the surface of the steam generating ball 4 is provided with a fixed grid frame 5;

[0044] The inside of the steam generating ball 4 is provided with a steam generating pool 401, and the steam connecting pipe 3 passes through the fixed grid 5 and the steam generating ball 4 and communicates with the steam generating pool 401; the bottom end of the steam turbine 2 is fixedly connected to the top of the water pump 6 through a pipeline , the water pump 6 is connected to the steam generating pool 401 in the steam generating ball ...

Embodiment 2

[0063] (1) Preparation of multi-dimensional assembled photothermal conversion phase change materials:

[0064] Put 0.1 g of carbon fiber cloth base into 30 mL of concentrated HNO3 solution (8 mol / L), heat it at 100 °C for 3 h, wash it repeatedly with water until neutral, and dry it in vacuum for 24 h to obtain activated carbon fiber cloth.

[0065] The activated carbon fibers were immersed in 30 mL of methanol solution containing cobalt nitrate hexahydrate (1.16 g) and dimethylimidazole (0.66 g), reacted at 80 ° C for 24 h, and washed the product three times with methanol solvent to remove by-products and impurities. Dry at 80 °C for 12 h to obtain carbon fiber cloth @2D-ZIF-Co precursor. The carbon fiber @2D-ZIF-Co precursor was carbonized at 1000°C for 3 hours under N2 atmosphere to obtain a multi-level structure carrier;

[0066] (2) Preparation of multi-dimensional assembled photothermal phase change materials:

[0067] Put 2.0 g of octadecane in a Petri dish and put it ...

Embodiment 3

[0070] (1) Preparation of multi-dimensional assembled photothermal conversion phase change materials:

[0071] Put 0.1 g of carbon nanotube substrate into 30 mL of concentrated HNO3 solution (8 mol / L), heat it at 100 °C for 3 h, wash it repeatedly with water until neutral, and dry it in vacuum for 24 h to obtain activated carbon nanotubes. The activated carbon nanotubes were impregnated in 30 mL of methanol solution containing nickel nitrate hexahydrate (1.16 g) and dimethylimidazole (0.66 g), reacted at 80 ° C for 24 h, and washed the product three times with methanol solvent to remove by-products and Impurities were dried at 80°C for 12 hours to obtain the carbon nanotube @2D-ZIF-Ni precursor material. The carbon nanotube @2D-ZIF-Ni precursor was carbonized at 600°C for 3 hours under N2 atmosphere to obtain a multi-level structure support;

[0072] (2) Preparation of multi-dimensional assembled photothermal phase change materials:

[0073] Put 2.0 g of paraffin in a Petri ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| photothermal conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com