High-temperature aerogel thermal insulation coating as well as preparation equipment and use method of high-temperature aerogel thermal insulation coating

A thermal insulation coating, high temperature gas technology, applied in chemical instruments and methods, alkali metal silicate coatings, coatings, etc., can solve the problems of inability to pre-process steps, low production efficiency and effect, low coating strength and toughness, etc. Achieve the effect of improving production efficiency and effect, improving mixing efficiency and effect, and large stirring range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment discloses a high-temperature airgel thermal insulation coating, which includes water glass, aqueous solution, functional materials, silane coupling agent, dimethyl silicone oil, film-forming agent, curing aid and film-forming aid.

[0046] Further, the functional material is one or more of silicon whiskers, ceramic whiskers, talc powder, and mica powder.

[0047] Further, the film-forming agent is one or more of sodium silicate, potassium silicate, styrene-acrylic emulsion, lithium silicate, acrylic emulsion, polyurethane emulsion, and the curing aid is magnesium oxide, aluminum oxide, fluorosilicon A kind of sodium acid;

[0048] Further, the film-forming aid is one or more of benzyl alcohol, ethylene glycol butyl ether, and propylene glycol phenyl ether alcohol ester-12.

[0049] After testing, the above-mentioned high-temperature airgel thermal insulation coating has a thermal conductivity of 0.038w / m K, a wet density of 600-700kg / m3, a dry density o...

Embodiment 2

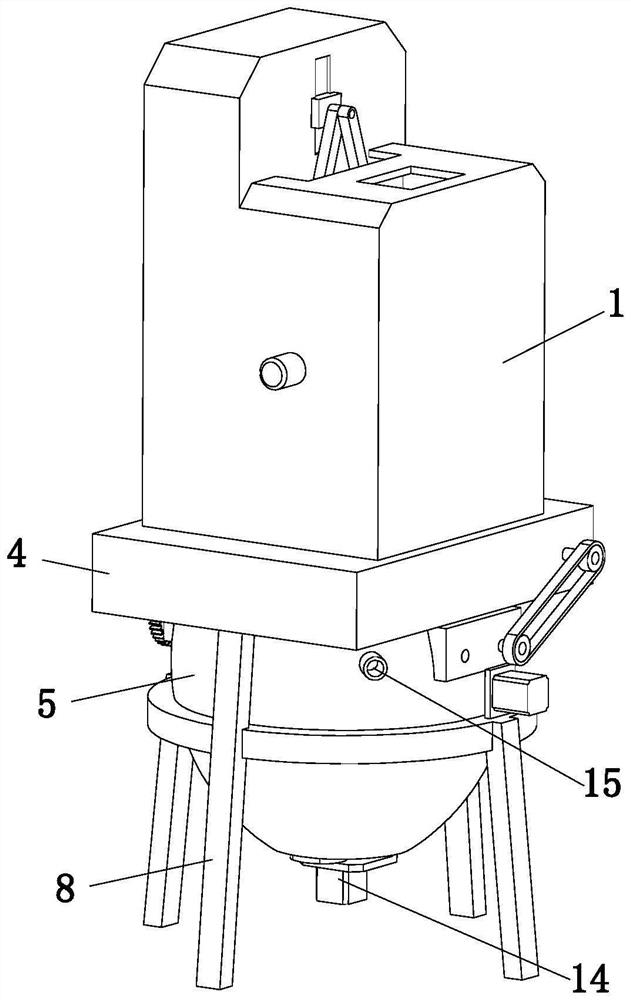

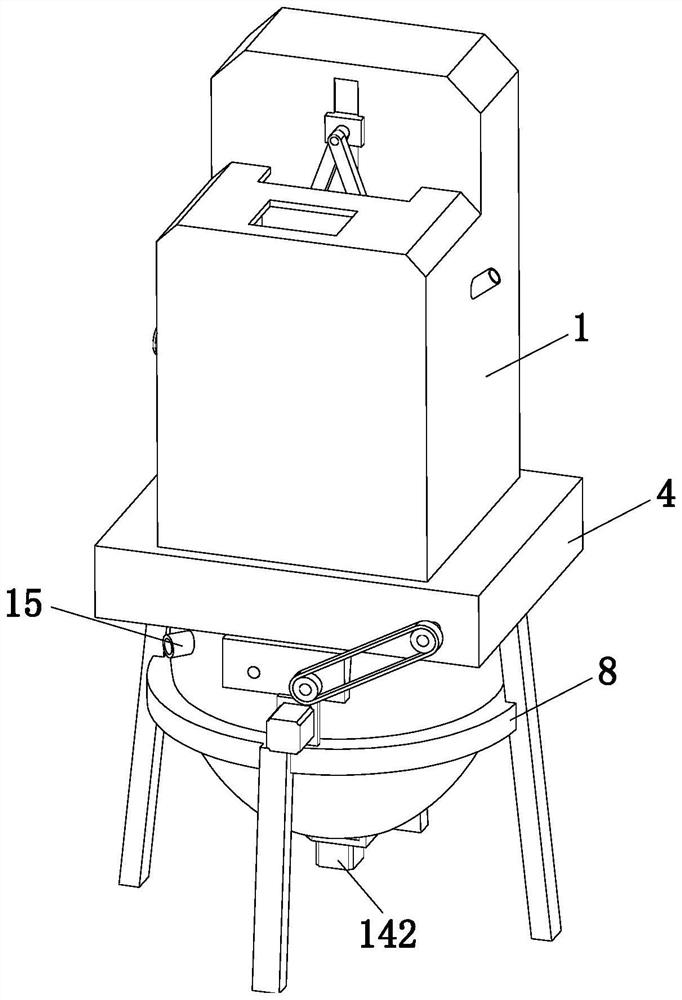

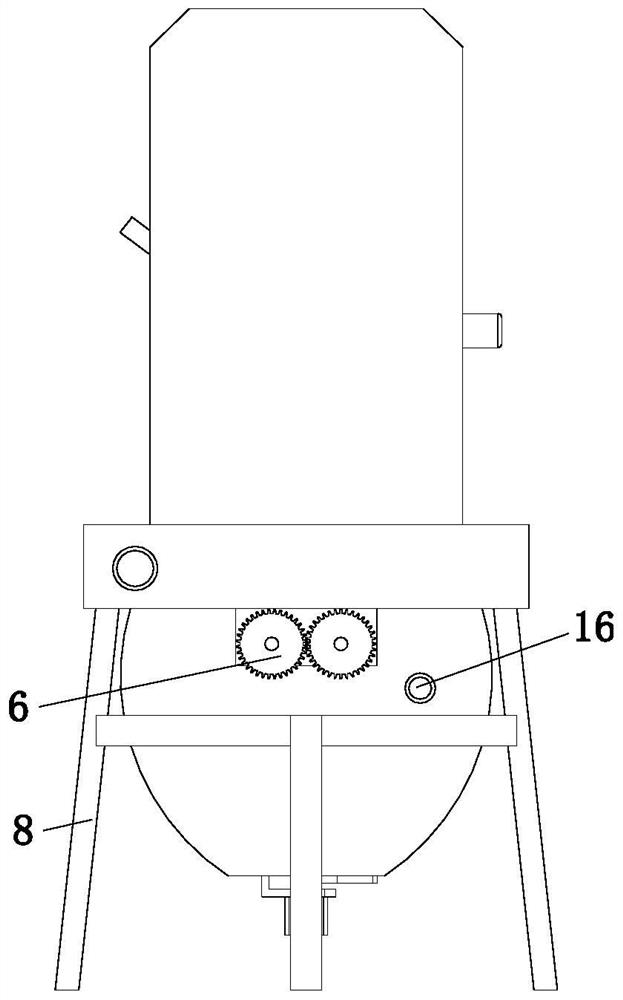

[0051] see Figure 1 to Figure 12 As shown, this embodiment discloses a preparation equipment for high-temperature airgel thermal insulation coatings, including an upper outer box 1, an agitation mechanism 2, an initial mixing mechanism 3, a middle box 4, a reaction tank 5, a crushing mechanism 6 and a secondary mixing mechanism 7. The middle box 4 is installed on the bottom of the upper outer box 1, the reaction tank 5 is fixed on the bottom of the middle box 4, and the outer wall of the reaction tank 5 is provided with a support leg frame 8, and the stirring mechanism 2 is installed on Inside the upper outer box 1 and directly above the primary mixing mechanism 3, the primary mixing mechanism 3 is installed in the middle layer box 4 and one end of the primary mixing mechanism 3 is in transmission connection with the pulverizing mechanism 6, and the pulverizing mechanism 6 is installed in the reaction tank 5, the two mixing mechanisms 7 are installed in the reaction tank 5 an...

Embodiment 3

[0060] This embodiment discloses a method for using the preparation equipment of high-temperature airgel thermal insulation coating, and the specific steps are as follows:

[0061] (1) by dropping the airgel paint raw material from the storage chamber 9 to the material receiving tank 31, wherein the dispersing motor 12 drives the dispersing shaft 10 connected to its output end and the dispersing blade 11 on the dispersing shaft 10 to rotate, Disperse the raw material of airgel coating to improve its subsequent mixing efficiency and effect;

[0062] (2) After the airgel paint raw material falls in the material receiving tank 31, feed raw materials and water that do not need pretreatment in the material receiving tank 31 through the feed pipe 13, and the drive motor 21 drives a motor that is connected to its output end. The interlocking assembly 24 works to initially mix the raw materials in the material receiving tank 31 to form silica airgel. Under the mutual transmission of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Wet density | aaaaa | aaaaa |

| Dry density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com