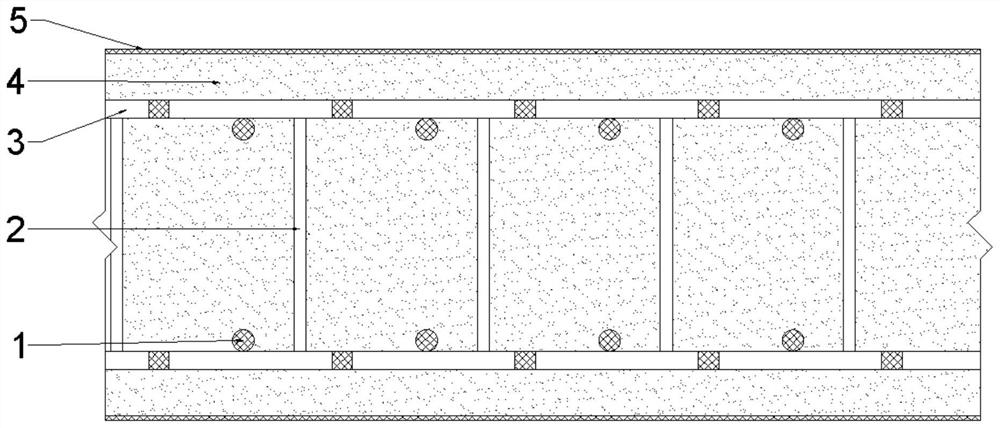

Novel seawater and sea sand concrete retaining wall structure and construction method

A concrete and seawater technology, applied in underwater structures, infrastructure engineering, hydraulic engineering, etc., can solve the problems of reducing the bearing capacity of concrete structures, affecting the durability of retaining wall structures, and spalling of concrete, so as to improve durability and strengthen Strength, effect of increasing compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

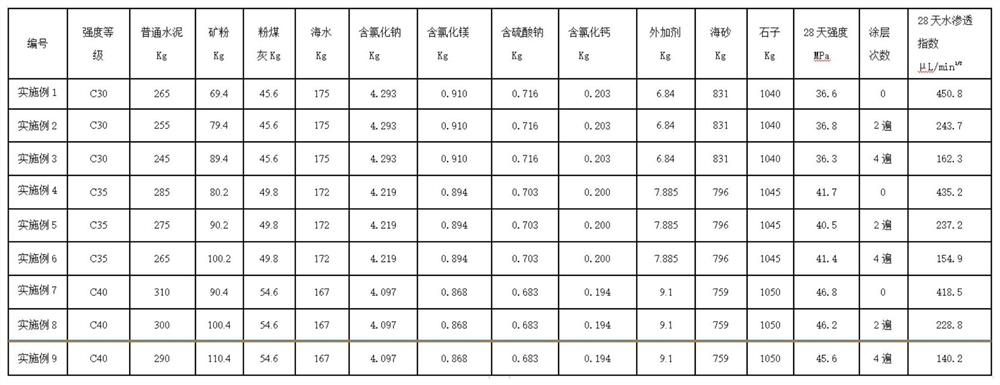

Embodiment 1

[0044] Embodiment 1: The composition of every cubic pump concrete is 265kg of cement, 69.4kg of mineral powder, 45.6kg of fly ash, 831kg of sea sand, 175kg of seawater, 6.84kg of admixture, and 1040kg of stone admixture. Carboxylic acid mother liquor 18%, sodium gluconate 1%, triethanolamine 1.8%, triisopropanolamine 1.5%, and water, each cubic concrete seawater contains 4.293kg of sodium chloride, 0.91kg of magnesium chloride, 0.716kg of sodium sulfate, chlorine Calcium 0.203kg, together with admixtures to form a pumping agent with enhanced performance.

Embodiment 2

[0045]Embodiment 2: the composition of every cubic pump concrete is cement 255kg, slag powder 79.4kg, fly ash 45.6kg, sea sand 831kg, seawater 175kg, admixture 6.84kg, stone 1040kg, each component of admixture is by mass percentage: Polycarboxylic acid mother liquor 19%, sodium gluconate 1.5%, triethanolamine 2.0%, triisopropanolamine 1.8%, and water, containing 4.293kg of sodium chloride, 0.91kg of magnesium chloride, and 0.716kg of sodium sulfate in every cubic concrete seawater. Calcium chloride 0.203kg, together with admixtures to form a pumping agent with enhanced performance, after 28 days of curing, apply the osmotic crystalline material twice, the osmotic crystalline material is composed of 20% magnesium fluorosilicate, fluorine Zinc silicate 1%, hydrofluoric acid 2.5%, fluorocarbon surfactant 2%, and water.

Embodiment 3

[0046] Example 3: according to the above-mentioned retaining wall structure, bind the fiber reinforcement and the fiber grid skeleton, pour C30 pumped concrete, and the composition of each cubic pumped concrete is 245kg of cement, 89.4kg of mineral powder, 45.6kg of fly ash, and 831kg of sea sand , seawater 175kg, admixture 6.84kg, stone 1040kg, each component of admixture is polycarboxylate mother liquor 20%, sodium gluconate 2.5%, triethanolamine 2.5%, triisopropanolamine 2% and water by mass percentage, each Cubic concrete seawater contains 4.293kg of sodium chloride, 0.91kg of magnesium chloride, 0.716kg of sodium sulfate, and 0.203kg of calcium chloride, together with admixtures to form a pumping agent with enhanced performance. After 28 days of curing, apply the permeable crystalline material 4 times The permeable crystalline material is composed of 25% magnesium fluorosilicate, 1.25% zinc fluorosilicate, 3.0% hydrofluoric acid, 1.5% fluorocarbon surfactant, and water in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com