Apricot kernel oil scald ointment as well as preparation method and application thereof

A technology of almond oil and scald ointment, which is applied in the field of medicine, can solve the problems of not being able to improve the microenvironment of injured tissues and the balance of collagen metabolism, and achieve the effects of improving the metabolic microenvironment, facilitating industrial production, and inhibiting excessive proliferation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

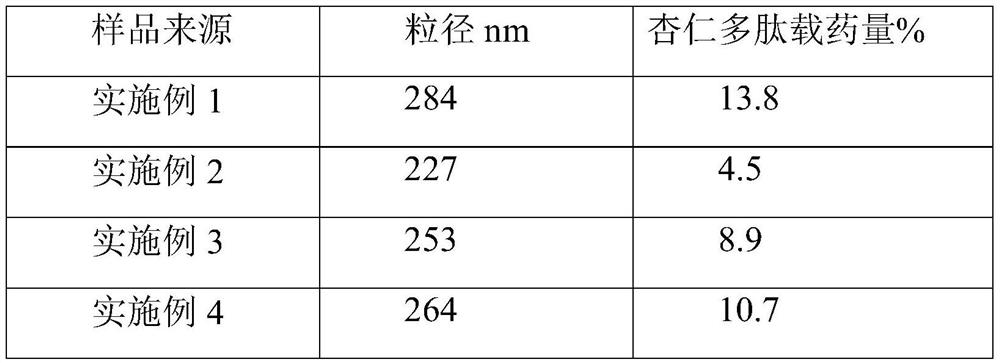

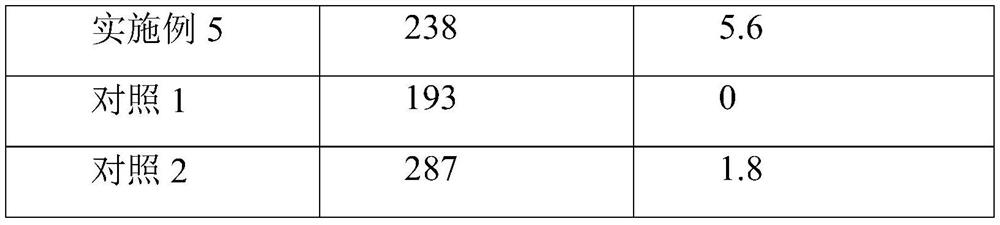

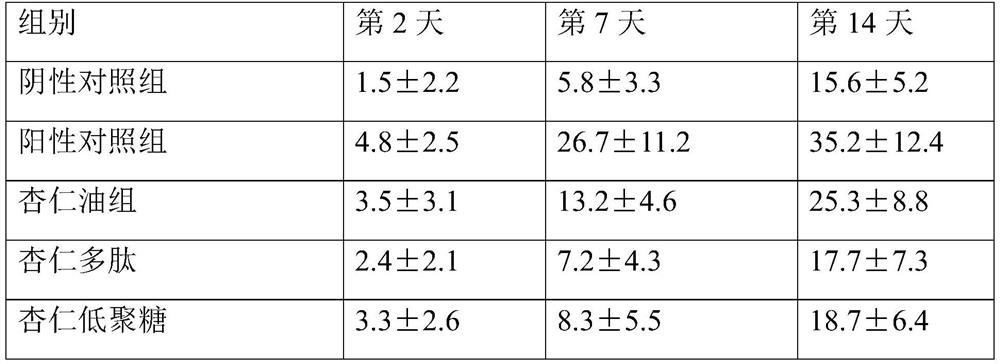

Examples

Embodiment 1

[0038] (1) 1 kg of almonds was crushed through a 10-mesh sieve, added with 10 g of immobilized neutral protease and 8 kg of 40°C pH5 acetate buffer for extraction for 1 hour, then centrifuged at 3000 rpm for 60 minutes, and the supernatant was collected as sweet almond oil, which was extracted with a molecular weight cut-off of 5 kDa membrane filtration, and the filtrate was freeze-dried for 24 hours to obtain 165 g of almond polypeptide;

[0039] (2) 1 kg of apricot pulp was added with 5 g of immobilized fructosidase and 8 kg of pH5 acetate buffer solution, reacted at 40° C. for 1 h and then filtered, and the filtrate was freeze-dried for 24 h to obtain 87 g of almond oligosaccharides;

[0040] (3) Add 5g lipase to 100g almond oil and react with 800g 40°C pH5 acetate buffer for 1 hour, then add 500g ethyl acetate and 50g apricot oligosaccharides, continue the reaction for 1 hour, then let it stand for 8 hours, and the upper layer is heated at 50°C, 0.01 MPa was concentrated a...

Embodiment 2

[0043] (1) 1 kg of almonds was crushed through a 30-mesh sieve, added with 100 g of immobilized alkaline protease and 30 kg of 60°C pH9 phosphate buffer for extraction for 3 hours, centrifuged at 5000 rpm for 30 minutes, and the upper layer was collected as sweet almond oil, and the lower layer was intercepted Membrane filtration with a molecular weight of 20kDa, and the filtrate was freeze-dried for 48 hours to obtain 235g of almond polypeptide;

[0044] (2) Add 50 g of immobilized lactase and 30-fold pH 9 phosphate buffer to 1 kg of apricot pulp, react at 60° C. for 3 h, filter, freeze-dry the filtrate for 48 h, and obtain 117 g of almond oligosaccharides;

[0045](3) Add 10g lipase to 100g almond oil and react with 3kg 60℃pH9 phosphate buffer for 3h, then add 1kg petroleum ether and 150g almond oligosaccharides, continue to react for 3h, then let it stand for 24h, and the supernatant is heated at 70℃, 0.1MPa Concentrate and dry for 8 hours to obtain 120 g of almond oil and ...

Embodiment 3

[0048] (1) 1 kg of almonds was crushed through a 20-mesh sieve, added 50 g of immobilized papain and 15 kg of 60°C pH6 Tris-HCl buffer solution for extraction for 2 hours, centrifuged at 4000 rpm for 40 minutes, and the upper layer was collected as sweet almond oil, and the lower layer was used Membrane filtration with a molecular weight cut-off of 10kDa, and the filtrate was freeze-dried for 36 hours to obtain 215g of almond polypeptide;

[0049] (2) Add 25 g of immobilized dextranase and 20 times of pH6 Tris-HCl buffer solution to 1 kg of apricot pulp, react at 60° C. for 2 h and filter, freeze-dry the filtrate for 36 h to obtain 104 g of almond oligosaccharides;

[0050] (3) Add 7g lipase and 1.5kg 60°C pH6 Tris-HCl buffer to 100g almond oil and react for 2h, then add 700g cyclohexane and 100g almond oligosaccharides, continue to react for 2h, let it stand for 16h, and the supernatant is passed through 60 °C, concentrated and dried at 0.05 MPa for 5 hours to obtain 132 g of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com