Crucible on-line remote observation control system of nano metal powder production system

A remote control system and nano metal powder technology, applied in general control system, program control, nanotechnology and other directions, can solve the problems of inaccurate measurement, fragile sensor, low production efficiency, etc., to reduce environmental pollution and improve smelting quality , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

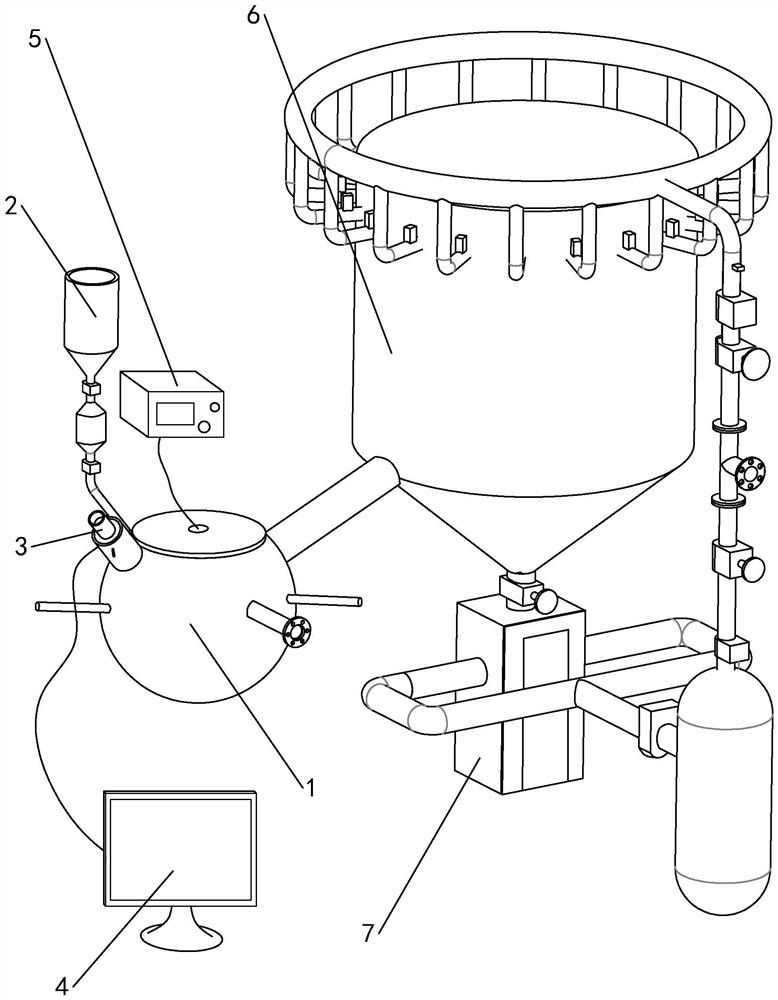

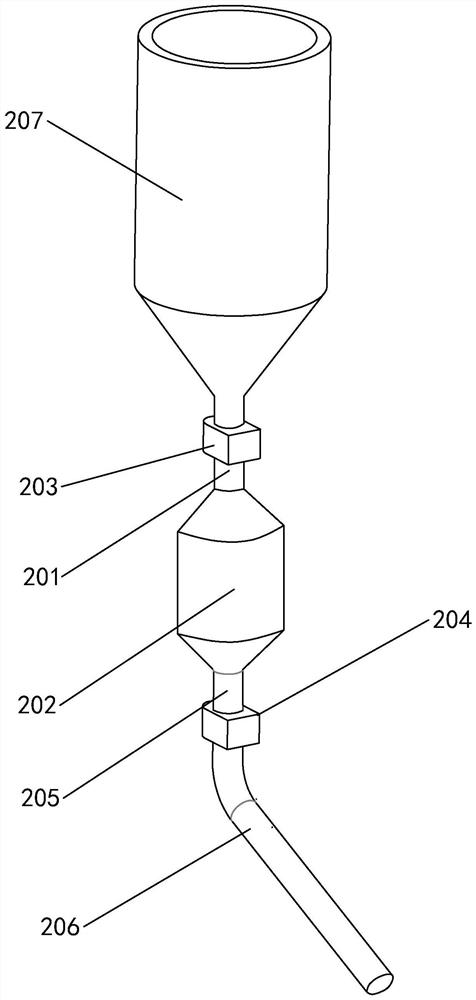

[0040] exist figure 1 , the crucible online remote observation and control system of the nano metal powder production system includes a smelting evaporation device 1, an integrated sensing device 3, an automatic isolation feeding device 2, an arc plasma controller 5, and a computer remote control system 4 , Condensing system 6 , Nano metal powder collecting device 7 .

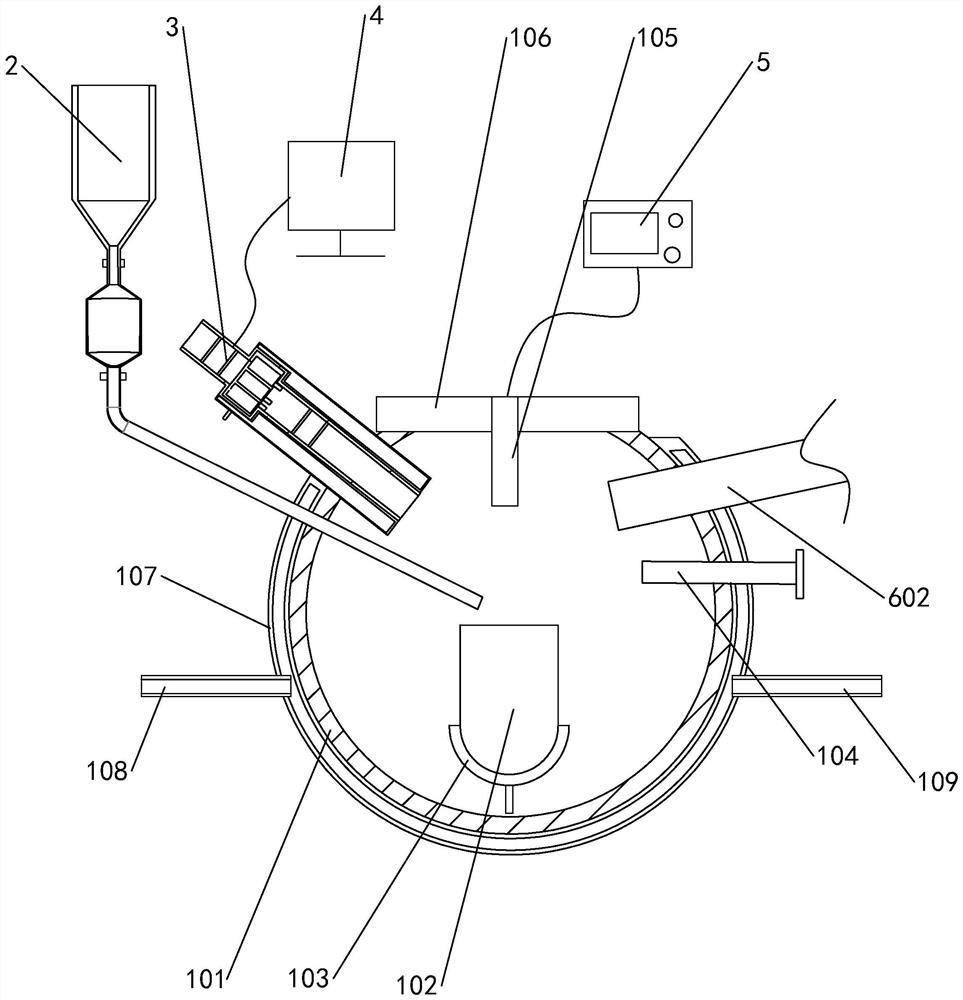

[0041] exist figure 2Among them, the smelting and evaporation device 1 includes a crucible 102, an inner casing 101, a cathode 105, an anode 103, a hydrogen-argon mixture input pipe 104, a cover plate 106, an outer casing 107, a cooling water input pipe B108, and a cooling water output pipe B109; the inner casing 101 and the outer casing 107 are spherical, and a cover plate 106 with an opening and detachment is provided at the top, and a cathode 105 is installed on the cover plate 106, and the cathode 105 is connected to the arc plasma controller 5 ; The inner cavity bottom of the inner shell 101 is equipped...

Embodiment 2

[0053] exist figure 1 , the crucible online remote observation and control system of the nano metal powder production system includes a smelting evaporation device 1, an integrated sensing device 3, an automatic isolation feeding device 2, an arc plasma controller 5, and a computer remote control system 4 , Condensing system 6 , Nano metal powder collecting device 7 .

[0054] exist figure 2 Among them, the smelting and evaporation device 1 includes a crucible 102, an inner casing 101, a cathode 105, an anode 103, a hydrogen-argon mixture input pipe 104, a cover plate 106, an outer casing 107, a cooling water input pipe B108, and a cooling water output pipe B109; the inner casing 101 and the outer casing 107 are spherical, and a cover plate 106 with an opening and detachment is provided at the top, and a cathode 105 is installed on the cover plate 106, and the cathode 105 is connected to the arc plasma controller 5 ; The inner cavity bottom of the inner shell 101 is equippe...

Embodiment 3

[0066] exist figure 1 , the crucible online remote observation and control system of the nano metal powder production system includes a smelting evaporation device 1, an integrated sensing device 3, an automatic isolation feeding device 2, an arc plasma controller 5, and a computer remote control system 4 , Condensing system 6 , Nano metal powder collecting device 7 .

[0067] exist figure 2 Among them, the smelting and evaporation device 1 includes a crucible 102, an inner casing 101, a cathode 105, an anode 103, a hydrogen-argon mixture input pipe 104, a cover plate 106, an outer casing 107, a cooling water input pipe B108, and a cooling water output pipe B109; the inner casing 101 and the outer casing 107 are spherical, and a cover plate 106 with an opening and detachment is provided at the top, and a cathode 105 is installed on the cover plate 106, and the cathode 105 is connected to the arc plasma controller 5 ; The inner cavity bottom of the inner shell 101 is equippe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com