Device and process for strengthening two-phase anaerobic digestion by utilizing Fenton iron sludge and iron-containing biochar

An anaerobic digestion and biochar technology, applied in the field of solid waste recycling, can solve the problems of slow mutual trophic metabolism, low efficiency of hydrolysis and acidification in the former phase, acid-producing bacteria and methanogens in the latter phase, etc., and achieves excellent promotion effect. , the effect of increasing redox and improving biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

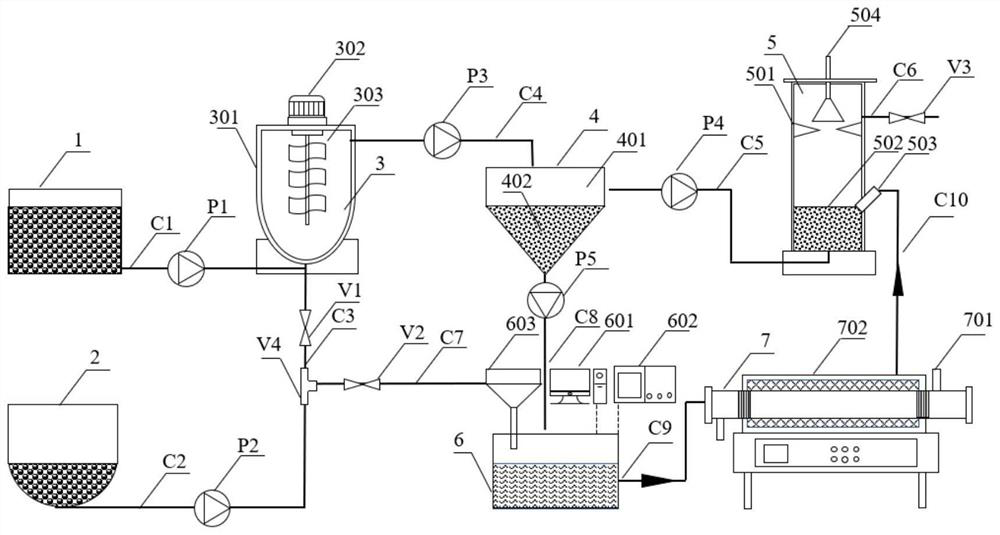

[0040] A process for processing organic solid waste using the above-mentioned device includes the following specific operation steps:

[0041] The excess sludge produced by a domestic sewage treatment plant is used as the raw material of organic solid waste, diluted with tap water to a solid content of about 6.3%, and the total COD concentration of the diluted sludge is about 65000g / L. The Fenton iron sludge produced by a landfill leachate treatment plant is used as the raw material. After dehydration, the solid content is 20%, the iron content (calculated as iron element) is 40%, and the organic content is 14%.

[0042] Up-flow anaerobic sludge bed reactors with working volumes of 1L and 2L were used as hydrolysis acidification reactors and methanogenesis reactors, respectively, and the anaerobic fermentation tank sludge was inoculated, so that the volume proportion of the introduced sludge in the reactors was 20% respectively. and 40%.

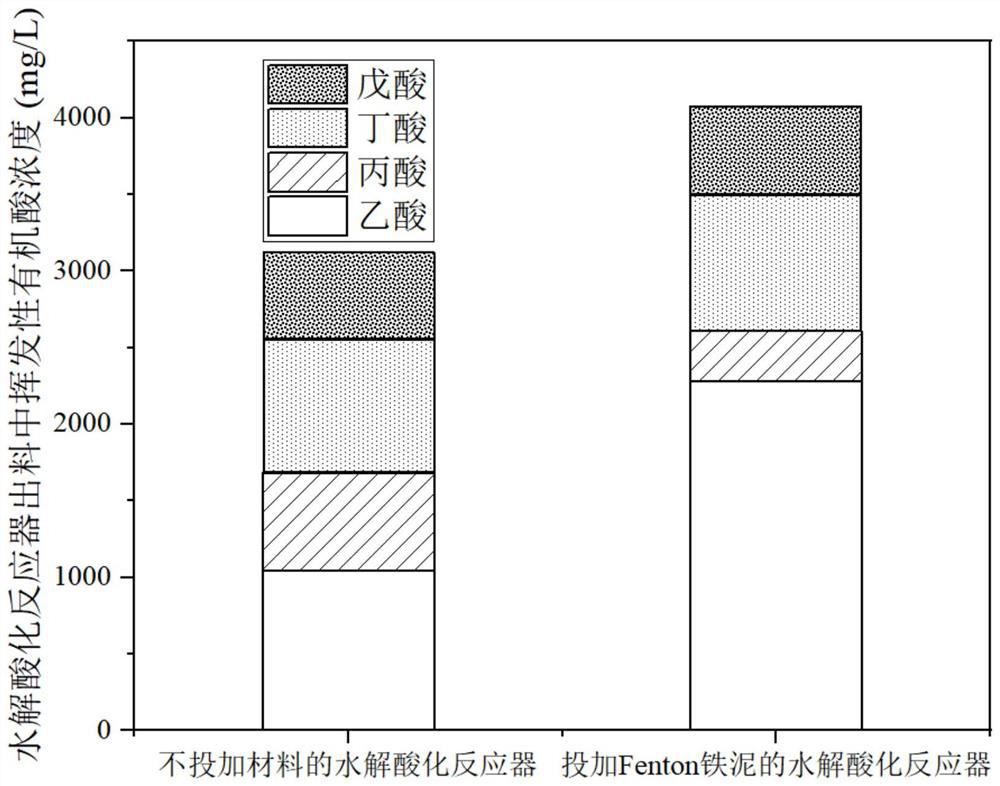

[0043] The dewatered Fenton iron slu...

Embodiment 2

[0052] A method for preparing iron-containing biochar using sludge and Fenton iron sludge, comprising the following steps:

[0053] The content of iron and carbon in Fenton iron sludge and anaerobic sludge was determined by elemental analyzer.

[0054] The Fenton iron sludge and the sludge from the sedimentation tank were mixed in the material conditioning tank to make the iron-carbon ratio of the mixture 1:1, and then loaded into a quartz boat.

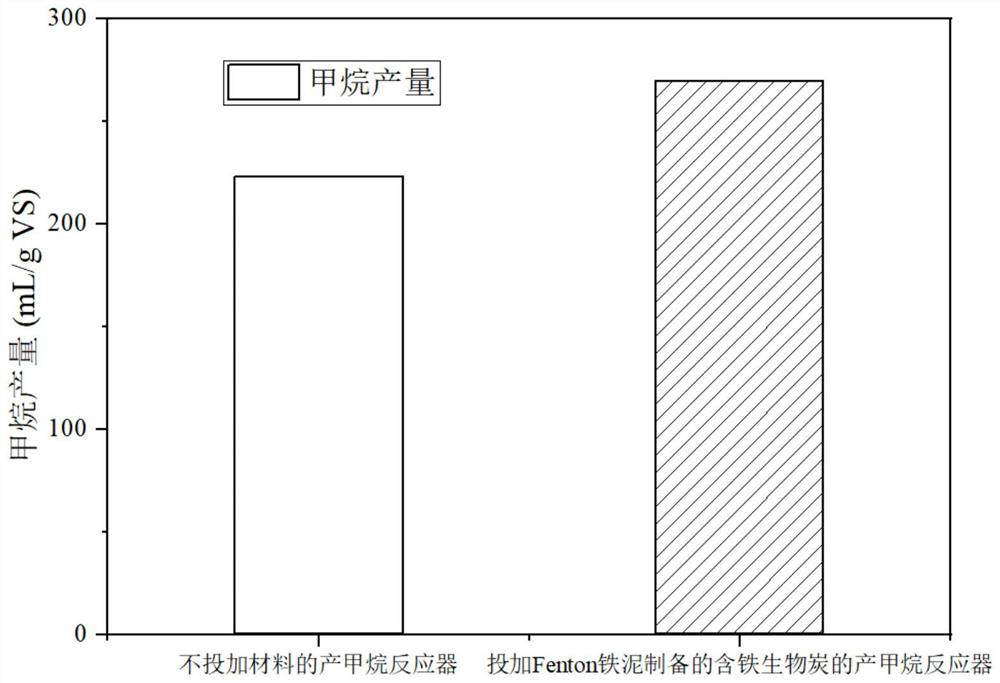

[0055] The quartz boat containing the mixture was sent into a tube furnace, and fired at 500° C. under nitrogen atmosphere for 2 hours to convert the biomass of the sludge into biochar and ferric iron into ferric tetroxide.

[0056] When the tube furnace naturally returned to room temperature, the fired biochar was taken out and ground into powder and passed through a 100-mesh sieve. The obtained sample was the iron-containing biochar prepared from Fenton iron sludge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com