Method for preparing lithium carbonate by purifying lithium-containing solution through adsorption-pressurized desorption method

A technology of lithium solution and lithium carbonate, which is applied in the field of lithium extraction and resource utilization, can solve the problem of few kinds of adsorbents, etc., and achieve the effects of simple process, cost reduction and increased cycle times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

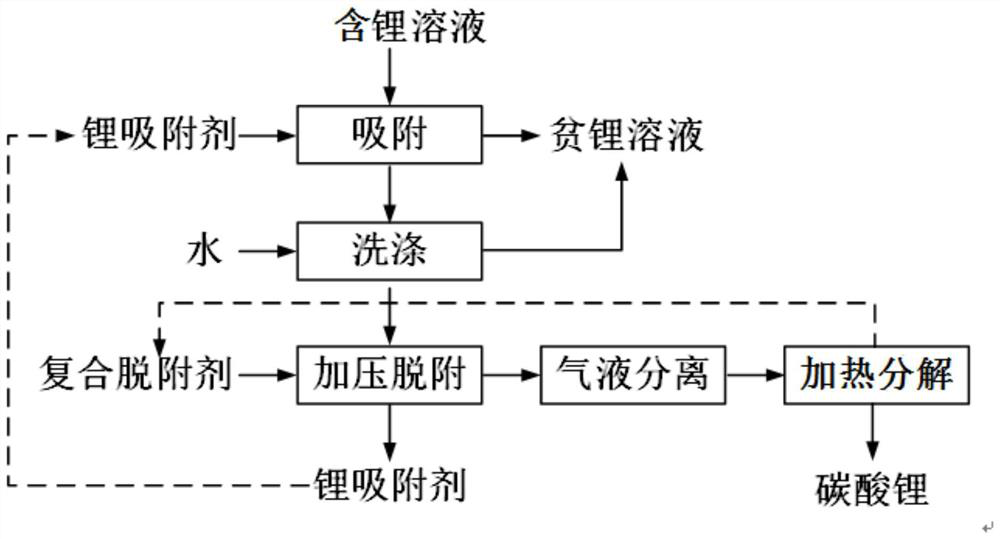

[0065] The present embodiment provides a method for purifying a lithium-containing solution to prepare lithium carbonate by an adsorption-pressurized desorption method. The process flow diagram of the method is as follows: figure 1 shown, including the following steps:

[0066] (1) the lithium-containing solution is adsorbed by a lithium adsorbent, the lithium-containing solution is a salt lake brine with a lithium element content of 1 g / L, the lithium adsorbent is a manganese-based ion sieve, and the temperature of the adsorption is 80 ° C, The flow rate of the lithium-containing solution is 30BV / h, and the saturated lithium adsorbent is obtained after the adsorption is saturated; the saturated lithium adsorbent is washed with water, the temperature of the water washing is 30°C, the flow rate is 25BV / h, and the amount of water is 3BV, to obtain a lean Lithium solution;

[0067] (2) desorbing the saturated lithium adsorbent obtained in step (1) by using a composite desorber, ...

Embodiment 2

[0072] The present embodiment provides a method for preparing lithium carbonate by purifying a lithium-containing solution by an adsorption-pressurized desorption method, and the method includes the following steps:

[0073] (1) The lithium-containing solution is adsorbed by a lithium adsorbent, the lithium-containing solution is raffinate wastewater with a lithium element content of 0.8 g / L, the lithium adsorbent is a lithium adsorption resin, and the adsorption temperature is 20 ° C , the flow rate of the lithium-containing solution is 2.5BV / h, and the saturated lithium sorbent is obtained after the adsorption is saturated; the saturated lithium sorbent is washed with water, the temperature of the water washing is 20 ° C, the flow rate is 5BV / h, and the amount of water is 1BV, to obtain a lithium-poor solution;

[0074] (2) desorbing the saturated lithium adsorbent obtained in step (1) by using a composite desorbent, wherein the composite desorber is SO 2 and the gas-liquid...

Embodiment 3

[0079] The present embodiment provides a method for preparing lithium carbonate by purifying a lithium-containing solution by an adsorption-pressurized desorption method, and the method includes the following steps:

[0080] (1) Lithium-containing solution is adsorbed by a lithium adsorbent, the lithium-containing solution is a precipitation lithium mother liquor with a lithium element content of 0.75g / L, and the lithium adsorbent is a manganese-based ion sieve, and the temperature of the adsorption is 40 ℃ ℃, the flow rate of the lithium-containing solution is 10BV / h, and the saturated lithium sorbent is obtained after the adsorption is saturated; the saturated lithium sorbent is washed with water, the temperature of the water washing is 40℃, the flow rate is 10BV / h, and the amount of water is 2BV, to obtain a lithium-poor solution;

[0081] (2) desorbing the saturated lithium adsorbent obtained in step (1) by using a composite desorbent, wherein the composite desorber is CO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com