Preparation method of high-purity boehmite for lithium battery diaphragm

A lithium battery separator, pure boehmite technology, applied in battery pack parts, chemical instruments and methods, alumina/hydroxide preparation, etc., can solve the problems of high cost, complex process, poor purity, etc. Electrochemical performance and safety performance, high chemical purity, and the effect of promoting stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

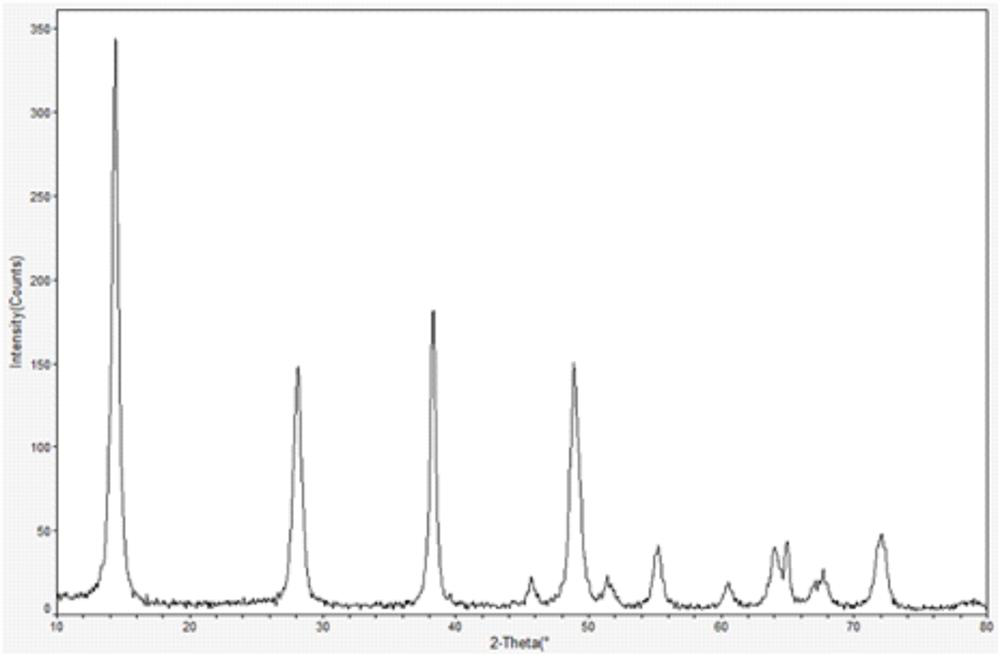

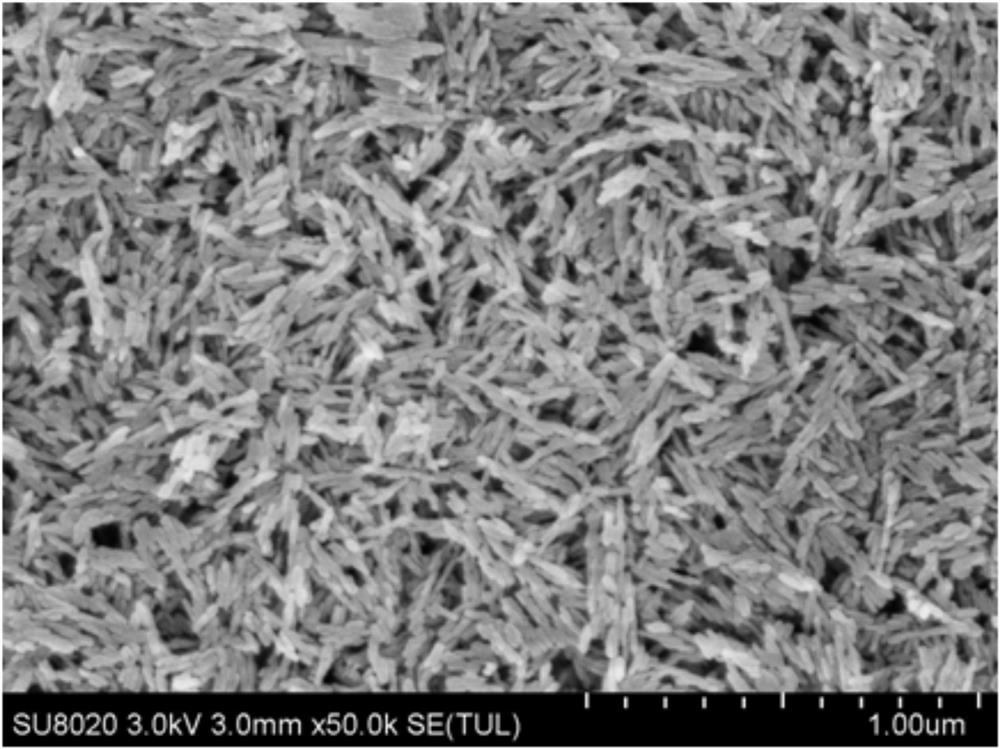

Image

Examples

Embodiment 1

[0030] (1) The activated high-purity aluminum powder and water are stirred and mixed at a mass ratio of 5:100 at room temperature to obtain a high-purity aluminum hydroxide slurry, and the high-purity aluminum hydroxide slurry is concentrated to a solid content of 15%;

[0031] (2) The particle size is D50=10μm, Na 2 O content is 0.02%, Fe 2 O 3 content of 0.01%, CaO content of 0.01%, SiO 2 The content of 0.008% pseudo-boehmite is added to the high-purity aluminum hydroxide slurry obtained after concentration during stirring, and the mass of pseudo-boehmite and high-purity aluminum powder is 0.5:100.

[0032] (3) nitric acid was added dropwise to the slurry containing pseudoboehmite and aluminum hydroxide during stirring, and the pH of the slurry was adjusted to 8.0;

[0033] (4) Transfer the above slurry to a high temperature and high pressure reaction kettle, the reaction temperature is 180°C, and the holding time is 3h;

[0034] (5) After the reaction, the boehmite prec...

Embodiment 2

[0038] (1) The activated high-purity aluminum powder and water are stirred and mixed at a mass ratio of 10:100 at room temperature to obtain a high-purity aluminum hydroxide slurry, and the high-purity aluminum hydroxide slurry is concentrated to a solid content of 15%;

[0039] (2) The particle size is D50=10μm, Na 2 O content is 0.02%, Fe 2 O 3 The content is 0.01%, the content of CaO is 0.01%, and the content of SiO2 is 0.008%. The pseudo-boehmite is added to the high-purity aluminum hydroxide slurry after concentration during the stirring process, and the quality of the pseudo-boehmite and the high-purity aluminum powder is 1.0: 100.

[0040] (3) acetic acid was added dropwise to the slurry containing pseudoboehmite and aluminum hydroxide during stirring, and the pH of the slurry was adjusted to 11.0;

[0041] (4) Transfer the above slurry to a high temperature and high pressure reaction kettle, the reaction temperature is 190°C, and the holding time is 7h;

[0042] (5...

Embodiment 3

[0046] (1) The activated high-purity aluminum powder and water are stirred and mixed at a mass ratio of 10:100 at room temperature to obtain a high-purity aluminum hydroxide slurry, and the high-purity aluminum hydroxide slurry is concentrated to a solid content of 15%;

[0047] (2) The particle size is D50=10μm, Na 2 O content is 0.02%, Fe 2 O 3 content of 0.01%, CaO content of 0.01%, SiO 2 The content of 0.008% pseudo-boehmite is added to the high-purity aluminum hydroxide slurry obtained after concentration during stirring, and the mass of pseudo-boehmite and high-purity aluminum powder is 0.5:100.

[0048] (3) nitric acid was added dropwise to the slurry containing pseudoboehmite and aluminum hydroxide during stirring, and the pH of the slurry was adjusted to 10.0;

[0049] (4) Transfer the above slurry to a high temperature and high pressure reaction kettle, the reaction temperature is 210°C, and the holding time is 3h;

[0050] (5) After the reaction, the boehmite pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com