Degradable composite film for heart occluder as well as preparation method and application of degradable composite film

A composite film and reaction technology, which is applied in the fields of medical formulation, surgery, drug delivery, etc., can solve the problems that are not conducive to occluder implantation and morphology observation, poor X-ray visualization of degradable flow-blocking membrane, and hindering the formation of normal new tissue, etc. Problems, to achieve the effect of facilitating adhesion and growth, improving X-ray imaging ability, and improving anticoagulant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Example 1. Preparation of gelatin derivatives (dopamine / double bond modified gelatin)

[0055] 5 g of gelatin (bloom value of 300 g) was dissolved in 100 ml of deionized water and heated to 60° C., and then 1 ml (1.035 g) of methacrylic anhydride was added to react at 60° C. for 1 h. The resulting mixed solution was dialyzed with a dialysis bag with a molecular weight cut-off of 10 KDa for 3 days and freeze-dried to obtain 4.3 g of a double bond-modified gelatin product. Dissolve 2g double bond modified gelatin in 100ml MES buffer (pH=5.5), then add 10mmol of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide (EDC), 10mmol of N-hydroxysuccinimide (NHS) and 10 mmol of dopamine hydrochloride, the solution was heated to 40 °C for 8 h. The mixed solution was dialyzed with a dialysis bag with a molecular weight cut-off of 10 KDa for 3 days and freeze-dried to obtain 3.5 g of a dopamine / double bond modified gelatin product.

Embodiment 2

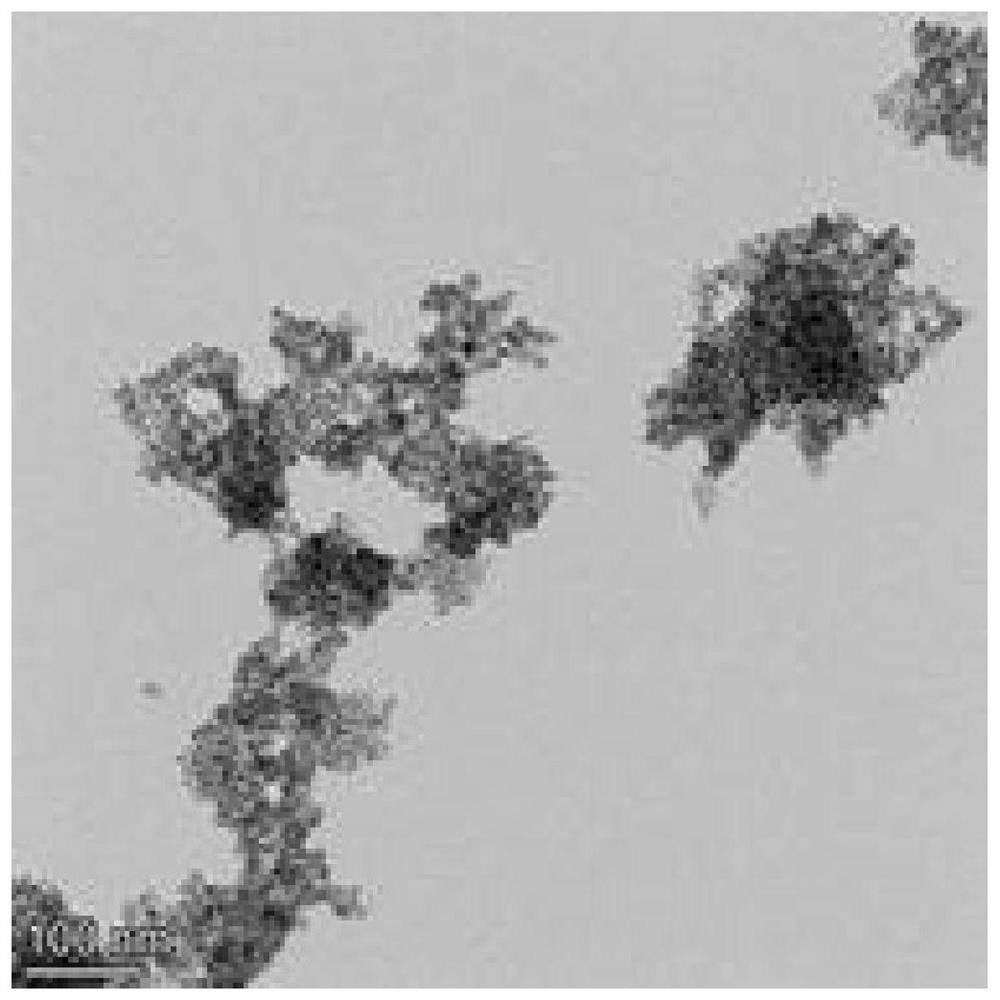

[0056] Example 2. Preparation of gelatin derivative-modified ceria particles

[0057] Dissolve 2 g of dopamine / double bond modified gelatin in 100 ml of deionized water, add 1.737 g of cerium nitrate hexahydrate, stir at room temperature for 1 h, then add concentrated ammonia water to adjust the pH to 8, and stir at room temperature for 24 h to obtain a gelatin derivative-modified dioxide Cerium particles, such as figure 1 As shown, the particle size is between 10-20 nm.

Embodiment 3

[0058] Example 3. Preparation of double bond modified polylactic acid film (PLA film)

[0059] The polylactic acid film was soaked in an isopropanol solution of polyethyleneimine (0.1 g / mL), heated at 50 degrees Celsius for 10 minutes, then ultrasonically cleaned with deionized water, and the cleaned polylactic acid film was soaked in a newly configured In a 0.5 wt% methacrylic anhydride aqueous solution, sodium hydroxide solution was used to adjust the pH of the solution to 8.0, after 3 hours of reaction at room temperature, ultrasonic cleaning was performed with deionized water, and then ultrasonic cleaning with ethanol was used to obtain a double bond modified polylactic acid membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com