Composite lithium metal negative electrode material, preparation method thereof and metal lithium battery

A technology for lithium metal batteries and metal negative electrodes, which can be applied to lithium batteries, negative electrodes, battery electrodes, etc., and can solve the problems of poor wettability between LLZO and lithium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides a method for preparing a composite lithium metal negative electrode material, comprising the following steps:

[0032] A) mix the skeleton material with the nitrate solution, and obtain the additive material after drying;

[0033] B) Mixing the additive material with molten metal lithium, and cooling to obtain a composite lithium metal negative electrode material.

[0034] The present invention firstly configures a nitrate solution, and the nitrate is preferably one or more of aluminum nitrate, magnesium nitrate, lithium nitrate, zinc nitrate, copper nitrate, nickel nitrate, tin nitrate, bismuth nitrate, antimony nitrate and iron nitrate ; The concentration of the nitrate solution is preferably 0.05-0.2 mol / L, more preferably 0.1-0.15 mol / L.

[0035] Then, the framework material is added to the nitrate solution, sonicated, and dried to obtain the additive material.

[0036] In the present invention, the type of the skeleton material...

Embodiment 1

[0049] A 0.1 mol / L nitrate aqueous solution was prepared, then CNTs were added to the above solution according to the mass ratio of nitrate:CNT=1:20, ultrasonicated for 30 min, and finally the above solution was dried to obtain CNT / nitrate powder.

[0050] Lithium metal was heated to 200°C to a molten state, and then different mass ratios (0.5%, 1% and 5%) of additives (CNT / nitrate powder) were added to the molten lithium.

[0051] The nitrate additive and the molten lithium were stirred at a constant temperature for 5 min until the mixture was uniform, and then cooled to room temperature to obtain a modified lithium composite negative electrode material.

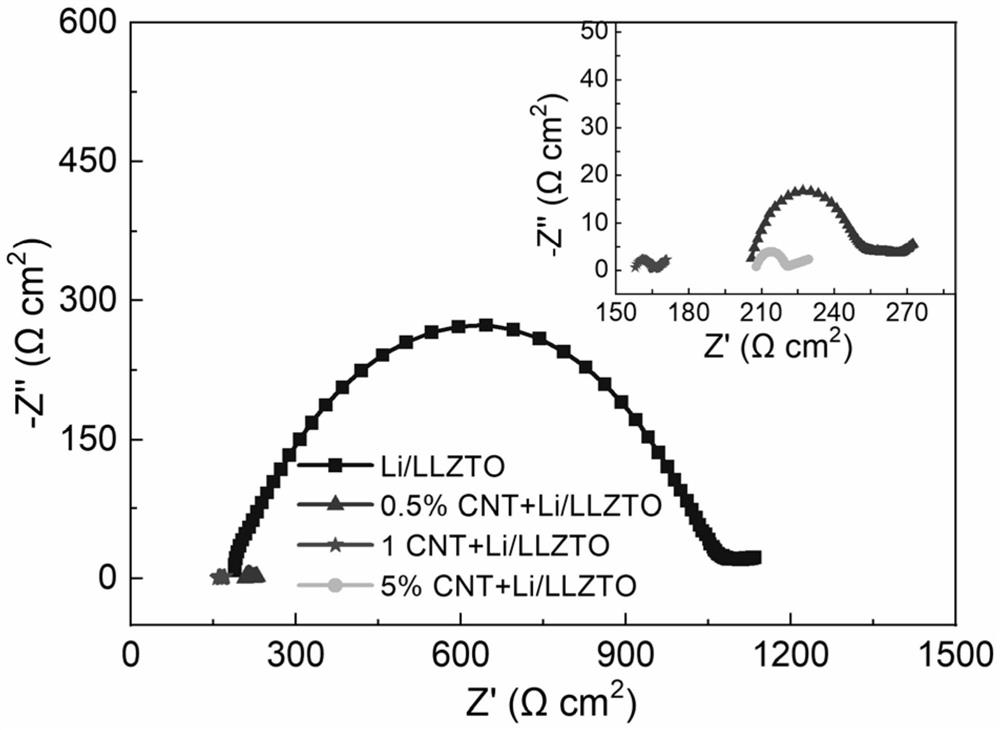

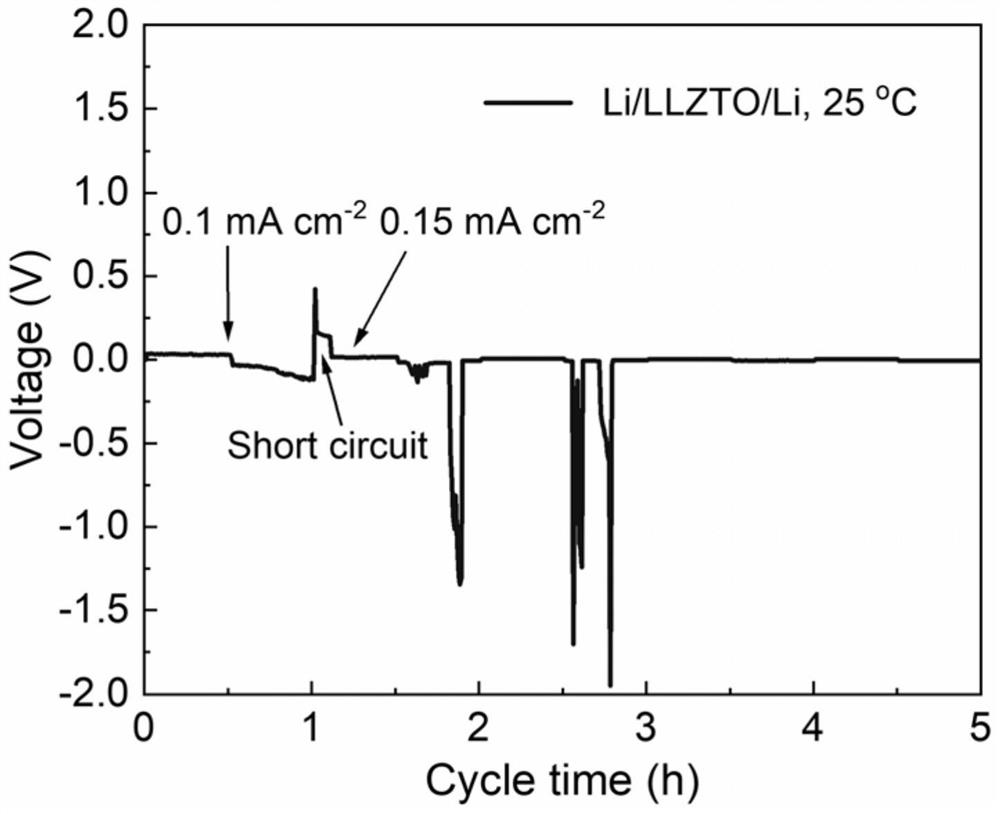

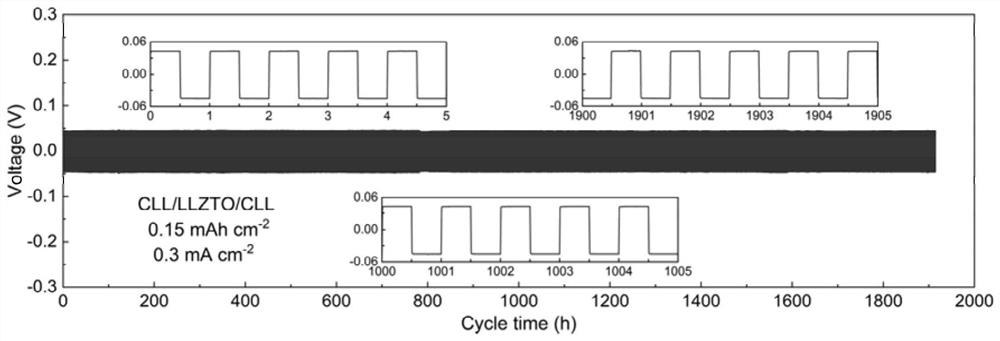

[0052] (1) The LLZO was placed in a glove box, and composite lithium was used as an electrode to assemble a composite lithium / / LLZTO / / composite lithium symmetrical lithium battery, and its interface impedance and cycle stability were evaluated.

[0053] The result is as figure 1 shown, by figure 1 It can be seen that when...

Embodiment 2

[0059] The carbon cloth (CC) was soaked in 0.1M nitrate solution to construct a three-dimensional composite negative electrode. During the soaking process, ultrasonication for 10 min can also improve the lithiophilicity of the carbon cloth. The lithium metal was heated to 200 °C, and the above three-dimensional composite electrode was immersed in the molten carbon cloth. In lithium, molten lithium can be automatically adsorbed into the carbon cloth and impregnated for 40s to obtain a composite negative electrode material.

[0060] Using carbon cloth and pure lithium sheet as electrodes, and using ester electrolyte without any additives, LNO-CC / / LE / / LNO-CC and Li / / LE / / Li symmetrical lithium batteries were assembled respectively. Cyclic Stability,

[0061] The result is as Image 6 As shown, the resulting LNO-CC / / LE / / LNO-CC symmetric cell can be operated at 1 mA cm -2 (1mAh cm -2 ) for 500 hours. In the comparison experiment, the overpotential fluctuation of the symmetric ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com