Burkholderia gladioli MEJ03 and application thereof

A technology of Burkholderia glabra, MEJ03, applied in Burkholderia gladiolus MEJ03 and its application field, can solve the problem of no degradation of phthalates and achieve the effect of promoting plant growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

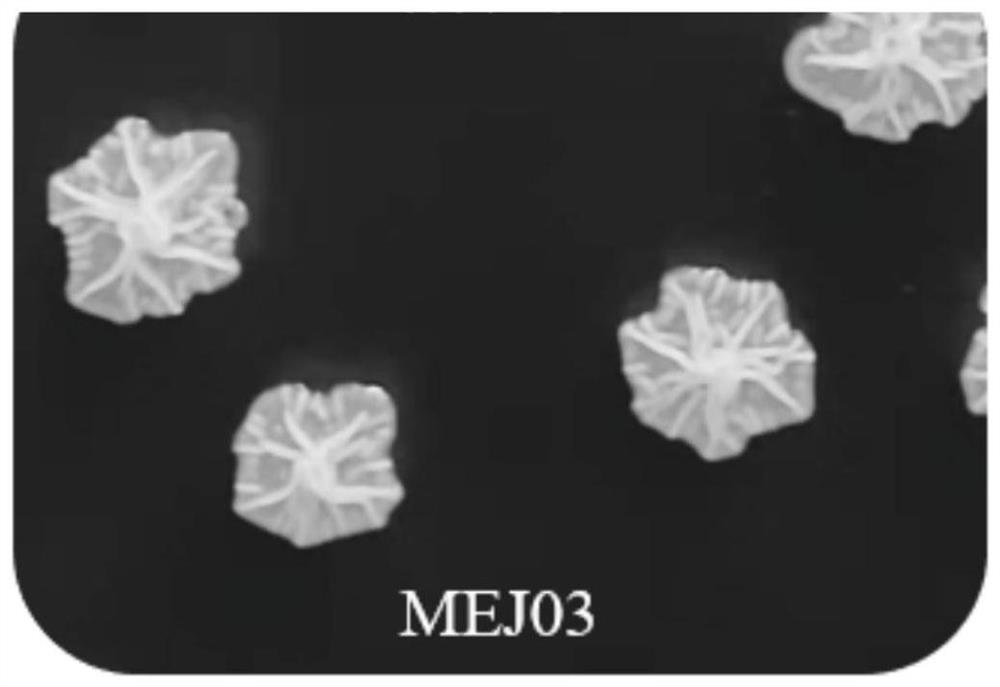

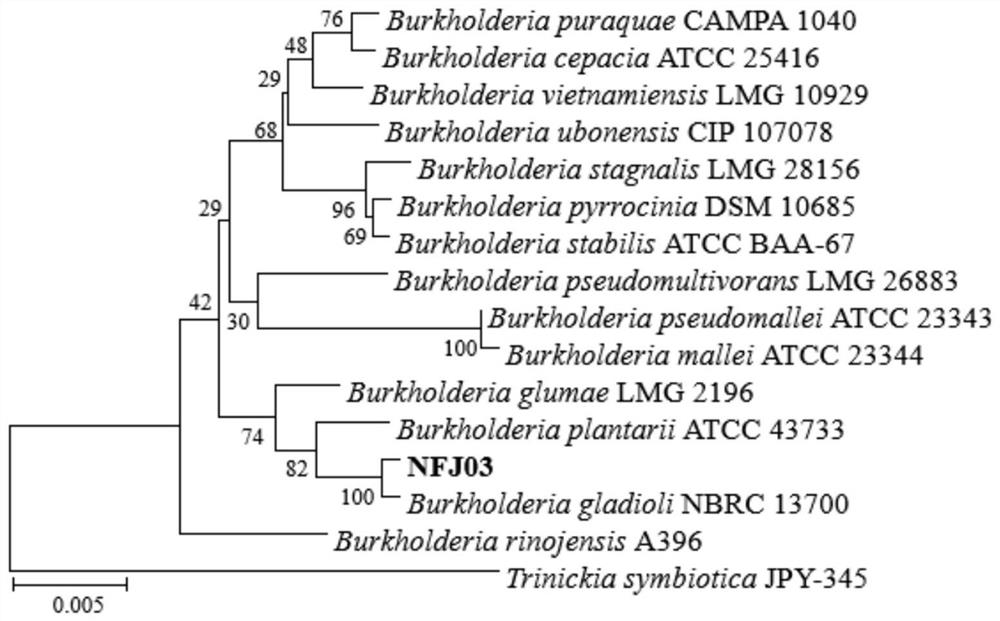

[0028] Example 1 Isolation and identification of Burkholderia gladioli strain MEJ03

[0029] The configuration of the medium is as follows: LB medium: yeast extract 5.0 g, tryptone 10.0 g, NaCl 10.0 g, add deionized water to 1.0 L, 121° C., 20 min, pH 7.0-7.2. MSM medium: KH 2 PO 4 0.5 g, K 2 HPO 4 0.5 g, CaCl 2 0.01 g, Fe 2 (SO 4 ) 3H 2 O 0.001 g, (NH 4 ) 2 SO 4 1.0g, MgSO 4 ·7H 2 O 0.2g, dilute to 1000mL with distilled water, pH7.0-7.2, sterilize at 121°C for 30min.

[0030] Bioaccumulation of DEHP-degrading bacteria: put 5g of the rhizosphere soil in the rice-wheat rotation area into a 250mL conical flask containing 50mL of MSM medium with 500mg / L DEHP as the sole carbon source, at 28°C, Incubate at 180 rpm for 5 days.

[0031] Preliminary screening: The soil solution after the above-mentioned cultivation was applied by gradient dilution on LB solid medium, and after culturing at 28°C for 5 days, single colonies with obvious differences in colony morphology...

Embodiment 2

[0038] Example 2 Effects of different temperatures and different initial pH on DEHP degradation by MEJ03

[0039] Pick a single colony of MEJ03, activate it overnight at 28°C, and inoculate it into 100 mL of MSM+Y medium containing 500 mg / L DEHP with 2% inoculum. The MSM+Y medium includes: add 1% (w) to the MSM medium. / v) Yeast extract.

[0040] Under different temperature and initial pH conditions, after culturing at 28 °C for 5 days, the samples were extracted with dichloromethane, and the samples were dissolved in methanol after rotary evaporation. Finally, the degradation rate of DEHP was determined by high performance liquid chromatography. The results are as follows Figure 4 As shown, MEJ03 degrades 500mg / L DEHP with high degradation rate (>50%) at 24℃-36℃ and initial pH of 5.0-9.0, the optimum degradation temperature is 28℃, and the optimum degradation initial pH is 7.0.

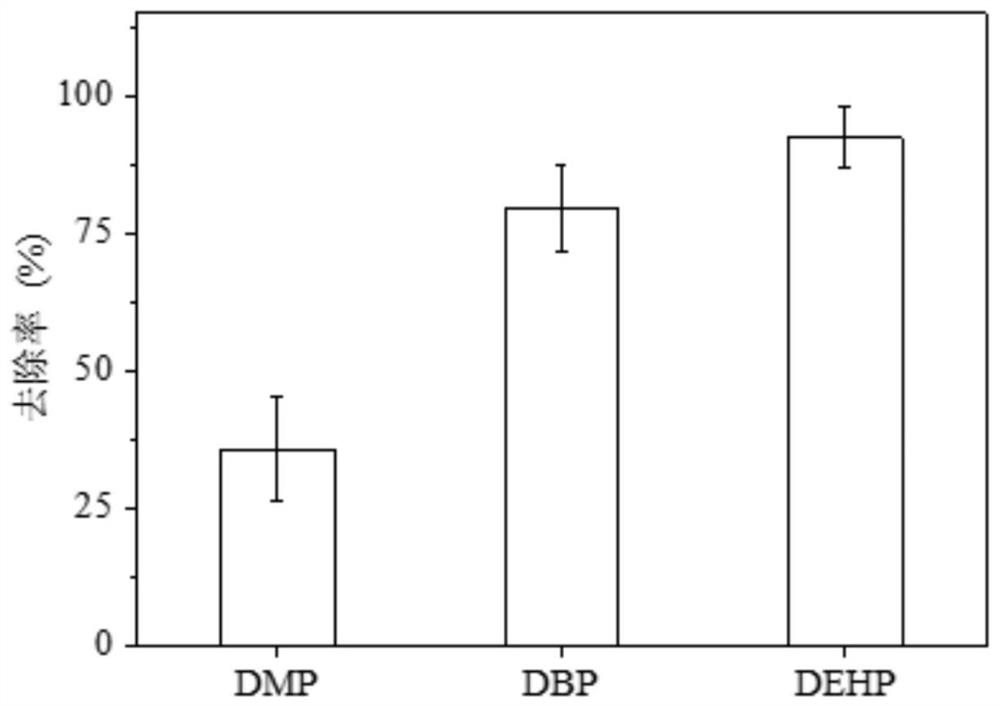

[0041] After testing, it was found that the degradation rate of this strain to 500mg / L phthala...

Embodiment 3

[0042] Example 3 Degradation kinetics of DEHP by MEJ03 under optimum degradation conditions

[0043] A single colony of MEJ03 was picked, activated at 28°C overnight, and then inoculated into 100 mL of MSM+Y medium containing 500 mg / L DEHP at 2% inoculum. Under the optimal degradation conditions, the degradation kinetics of MEJ03 to 500mg / L DEHP are as follows: Figure 5 As shown, with the increase of culture time, the degradation rate of MEJ03 to 500 mg / L DEHP increased continuously, and the degradation rate of MEJ03 to 500 mg / LDEHP could reach more than 94% after 4 days of culture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com