Negative pole piece of sodium ion battery, electrochemical device and electronic equipment

A technology of sodium-ion batteries and negative pole pieces, applied in the field of energy storage, can solve the problems of sodium-ion batteries that are difficult to realize commercial application, poor chemical stability, and easy to produce dendrites, etc., to achieve the suppression of the formation of sodium dendrites, high safety performance, the effect of reducing the overpotential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] As an optional technical solution of the present application, the preparation method of the above-mentioned negative pole piece comprises the following steps:

[0050] The carbon material is put into a mixed solution of concentrated sulfuric acid and concentrated nitric acid with a volume ratio of 3:1 and stirred for 1 to 6 hours, and the reaction time is controlled to control the oxygen content;

[0051] The reacted carbon material was washed with deionized water, filtered, put into an oven, and dried at 80°C;

[0052] The dried carbon material and polymer binder are added to the solvent and stirred into a uniform slurry, so that the slurry is coated on the negative electrode current collector (specifically, copper / aluminum foil), and dried to obtain a pole piece; wherein , the solvent can be selected from at least one of water, acetone, N-methylpyrrolidone, dimethylformamide, and ethanol;

[0053] The pole piece is put into a physical vapor deposition device, and a u...

Embodiment

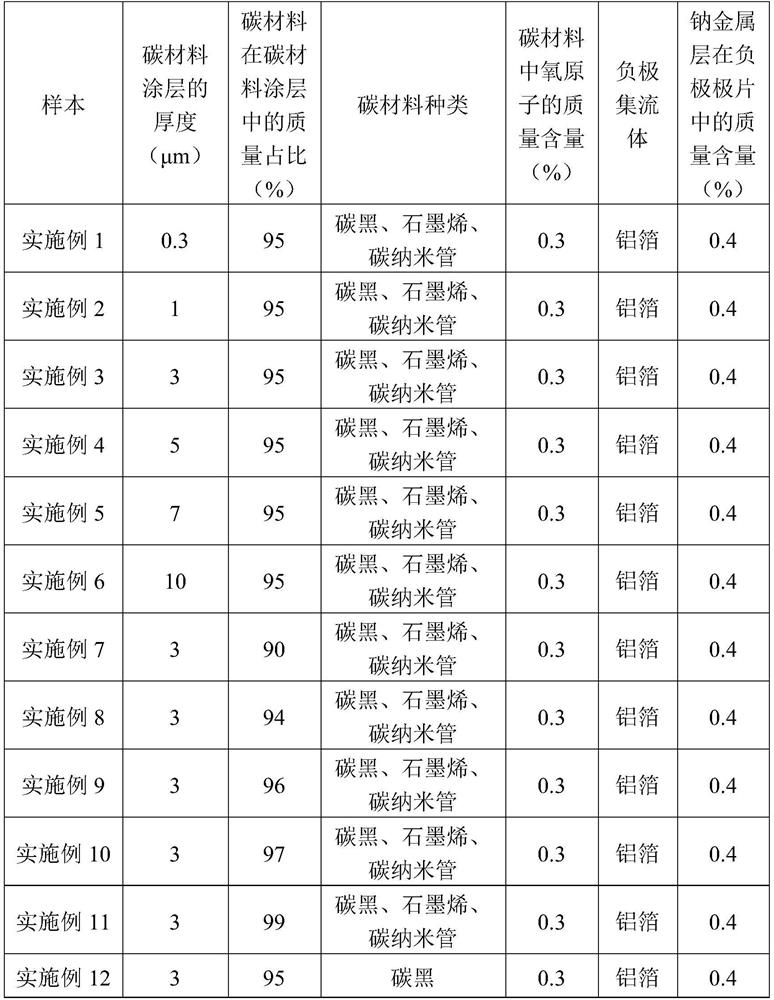

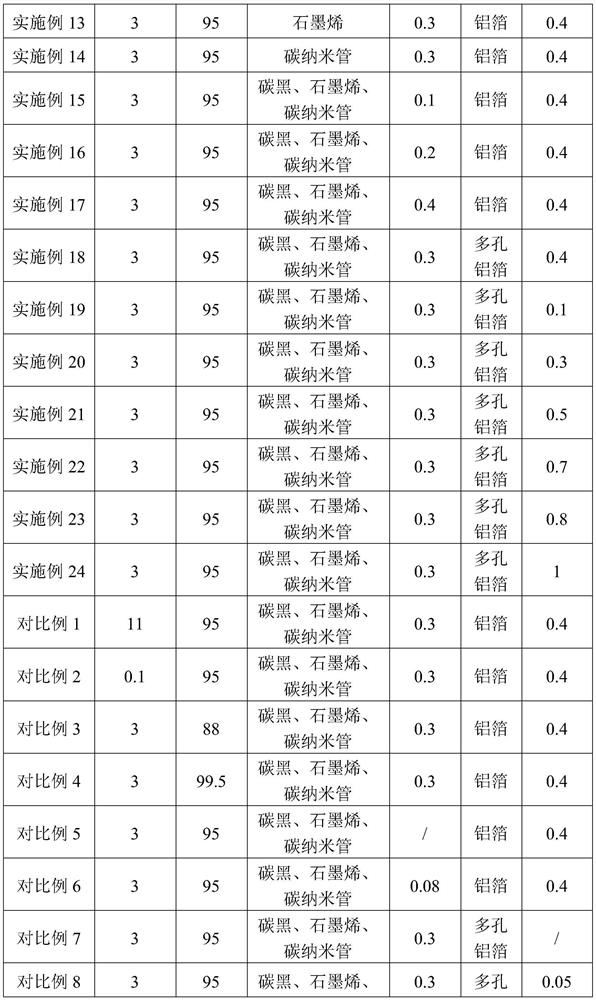

[0072] The following examples describe the disclosure of the present application in more detail, and these examples are provided for illustrative purposes only, as various modifications and changes within the scope of the disclosure of the present application will be apparent to those skilled in the art. Unless otherwise stated, all parts, percentages, and ratios reported in the following examples are on a weight basis, and all reagents used in the examples are either commercially available or synthesized according to conventional methods, and can be directly Used without further processing, and the instruments used in the examples are commercially available.

[0073] 1) Preparation of positive electrode sheet

[0074] 10wt% polyvinylidene fluoride binder was fully dissolved in N-methylpyrrolidone, 10wt% carbon black conductive agent and 80wt% Na were added. 4 Fe 3 (PO 4 ) 2 (P 2 O 7 ) The positive electrode active material is made into a uniformly dispersed positive ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com