Method for preparing pure alpha-phase molybdenum carbide catalyst through one-step carbonization, catalyst and application

A catalyst, molybdenum carbide technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, carbides, etc., can solve the problems of high corrosion resistance of equipment, loss of activity, high content of precious metal Pt, etc., to achieve excellent water vapor transformation performance, lower carburizing temperature, and lower precious metal content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

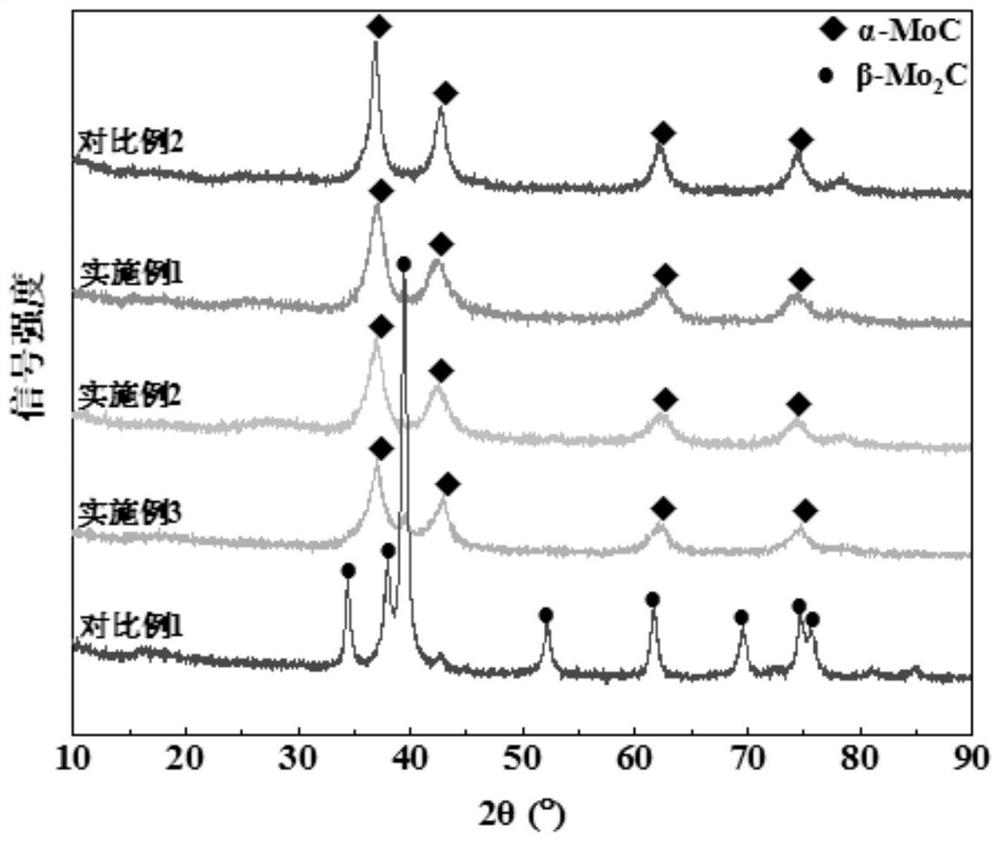

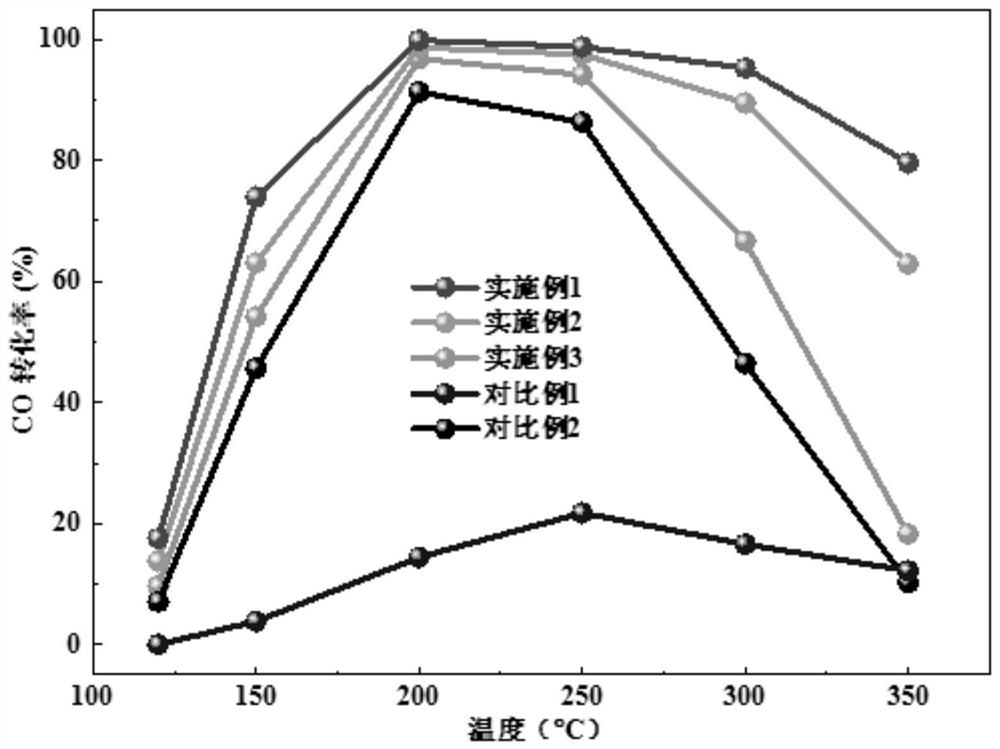

Embodiment 1

[0032] (1) To prepare molybdenum oxide, flame spray method can be used. The specific operation of the flame spray method is as follows: 34.945g of molybdenum acetylacetonate is dissolved in 100ml of benzyl alcohol, ultrasonically stirred for about 1h at room temperature to make it evenly mixed, and then 100ml of diethylhexanoic acid (EHA) is added to the solution, Ultrasonic stirring was carried out at room temperature for more than 1 h to make the solution as uniform as possible to prepare a 0.5 mol / L mixed precursor solution; the prepared solution was pumped into the flame at a speed of 5 ml / min with a syringe. The flame combustion gas is a mixture of methane (0.6L / min) and oxygen (1.9L / min), and the mixture is ejected from a 2mm diameter nozzle. A gas distribution plate is used (including a cylindrical container with one end closed and the other open open, the surrounding edges of the gas distribution plate with gas through holes are tightly connected with the open end of t...

Embodiment 2

[0041] The steps and process conditions of the present embodiment are the same as in Example 1, and the difference between them is only the following point: Measure 0.5ml of 0.04g / ml of RhCl 3 The solution was added to 1 g of MoO 3 , Rh / MoC with a loading mass percentage of 1% was prepared x catalyst.

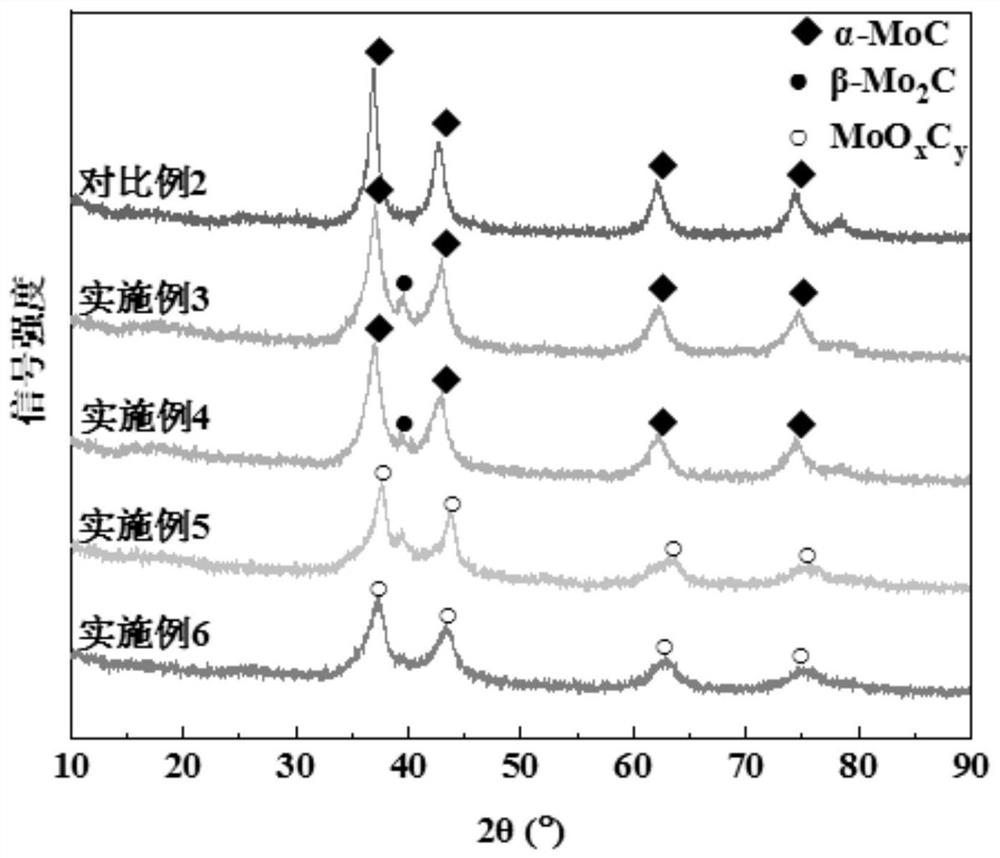

Embodiment 3

[0043] The steps and process conditions of the present example are the same as those of Example 1, and the difference between them is only the following point: Measure 0.31ml of 1.6mg / ml of RhCl 3 The solution was added to 1 g of MoO 3 , Rh / MoC with a loading mass percentage of 0.025% was prepared x catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com