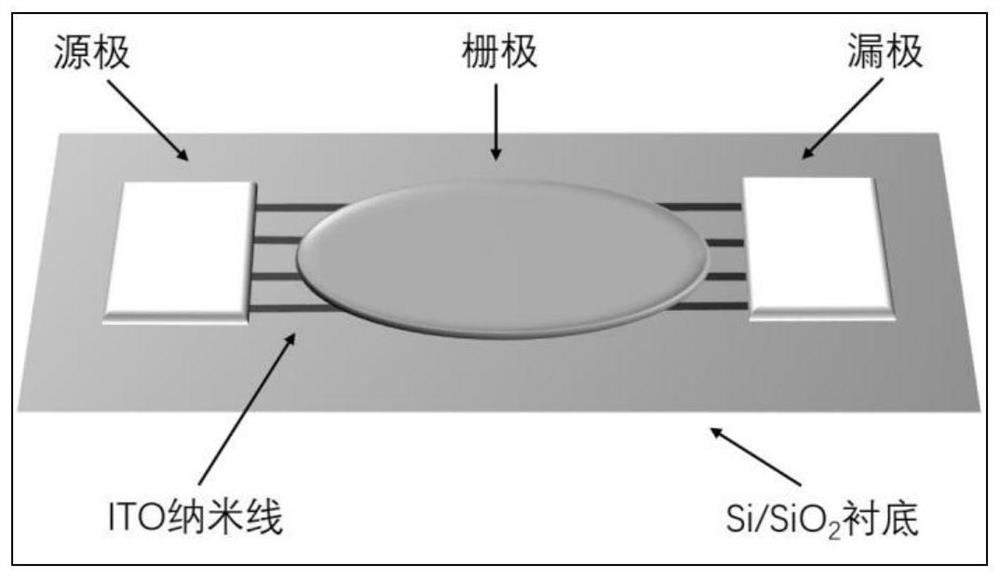

Three-terminal artificial synaptic device based on digital controllable printing ITO nanowire and preparation method of three-terminal artificial synaptic device

A technology of synaptic devices and nanowires, applied in the field of microelectronics, can solve the problems of high cost, complicated operation and cumbersome process of sputtering, and achieve the effects of stable chemical properties, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) The Si / SiO 2 The substrates were ultrasonically cleaned with deionized water, isopropanol, acetone and anhydrous ethanol for 30 minutes, respectively, and then their surfaces were blown dry with nitrogen;

[0037] (2) Mix the two reagents with a mass ratio of N,N-dimethylformamide: anhydrous ethanol=20:1 to prepare a mixed solvent; mix the mass ratio of polyvinylpyrrolidone:indium nitrate hydrate=1:1.2, chlorine The reagent of stannous dihydrate:indium nitrate hydrate=1:6.5 is dissolved in the mixed solvent, and stirred with a magnetic stirrer at a temperature of 50 ° C for 6 hours to configure the precursor solution required for printing; in the precursor solution The mass concentration of polyvinylpyrrolidone is 10.4%;

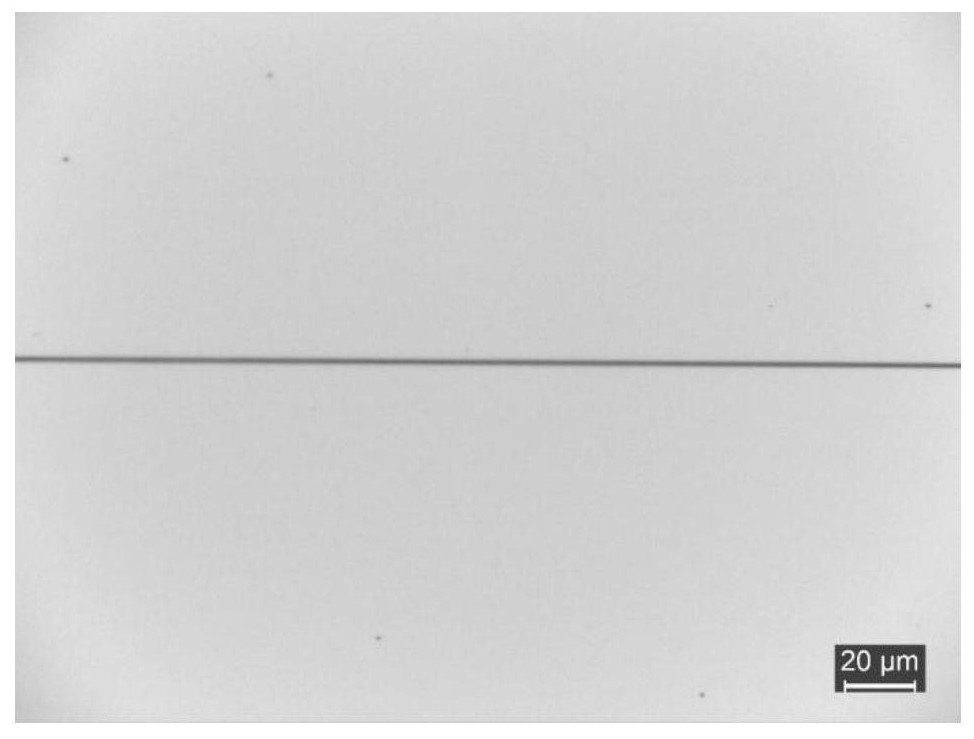

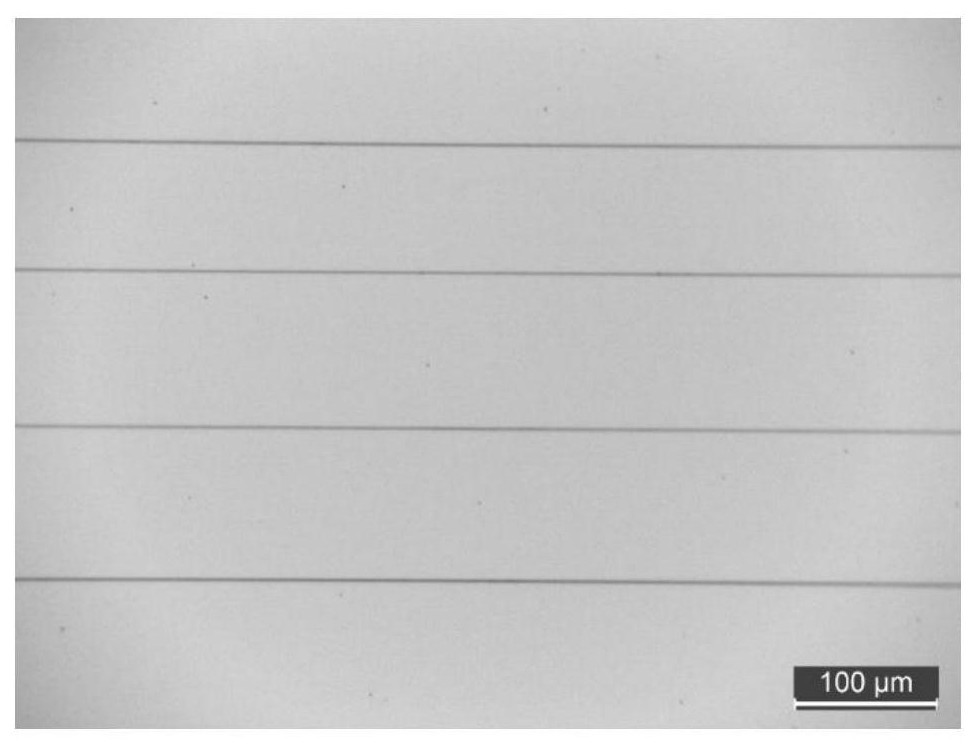

[0038](3) using an electrofluidic printer to print the precursor solution configured in step (2) as ITO nanowires, wherein a high voltage of 0.65kV is applied on the syringe needle, and the distance from the syringe needle to the substrate is set...

Embodiment 2

[0046] (1) The Si / SiO 2 The substrates were ultrasonically cleaned with deionized water, isopropanol, acetone and anhydrous ethanol for 30 minutes respectively, and then the surfaces were blown dry with nitrogen gas;

[0047] (2) Mix the two reagents with a mass ratio of N,N-dimethylformamide: anhydrous ethanol=10:1 to prepare a mixed solvent; mix the mass ratio of polyvinylpyrrolidone:indium nitrate hydrate=1:2, chlorine Tin bisulfite dihydrate: indium nitrate hydrate = 1:10 reagent is dissolved in the mixed solvent, and stirred at a temperature of 40 ° C for 12 hours with a magnetic stirrer to configure the precursor solution required for printing; in the precursor solution The mass concentration of polyvinylpyrrolidone is 11%;

[0048] (3) Using an electrofluidic printer, the precursor solution configured in step (2) was printed as ITO nanowires, wherein a high voltage of 1.1 kV was applied on the syringe needle, the distance from the syringe needle to the substrate was se...

Embodiment 3

[0054] (1) The glass substrate was ultrasonically cleaned with deionized water, isopropanol, acetone and absolute ethanol for 30 minutes, and then the surface was dried with nitrogen;

[0055] (2) Mix the two reagents with a mass ratio of N,N-dimethylformamide: anhydrous ethanol=6:1 to prepare a mixed solvent; mix the mass ratio of polyvinylpyrrolidone:indium nitrate hydrate=1:2, chlorine Tin bisulfite dihydrate: indium nitrate hydrate = 1:20 reagent is dissolved in the mixed solvent, and stirred at 25°C for 12 hours with a magnetic stirrer to configure the precursor solution required for printing; in the precursor solution The mass concentration of polyvinylpyrrolidone is 9%;

[0056] (3) Using an electrofluidic printer, the precursor solution configured in step (2) was printed as ITO nanowires, wherein a high voltage of 1.3 kV was applied on the syringe needle, the distance from the syringe needle to the substrate was set to 4 mm, and the syringe needle was set to 4 mm. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com