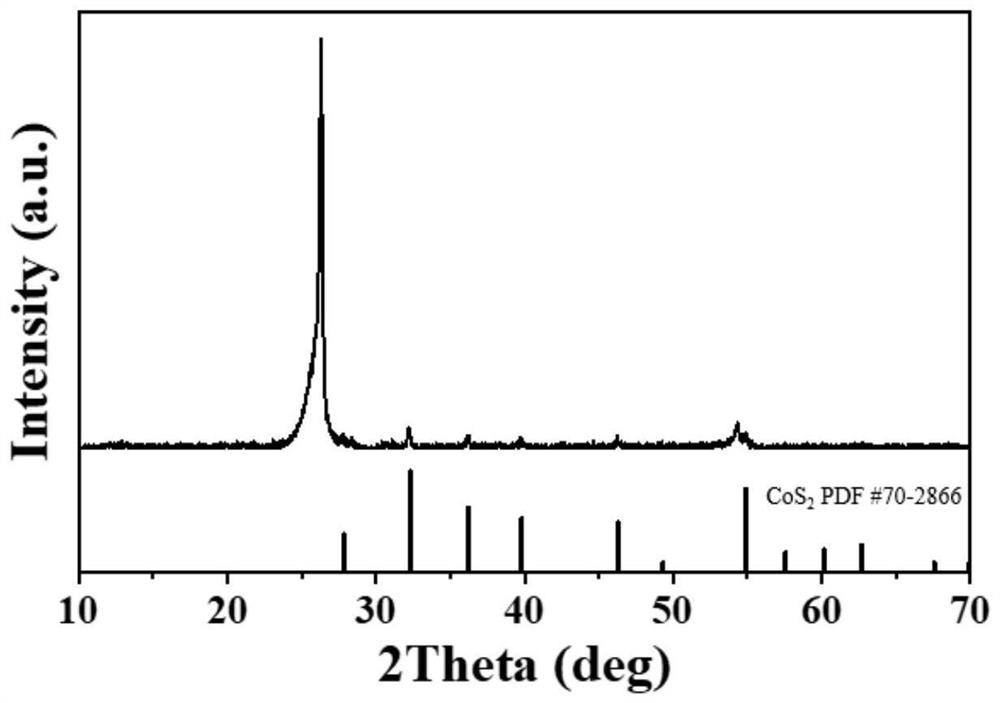

CoS2 isomeric composite material as well as preparation method and application thereof

A technology of isomeric and composite materials, applied in chemical instruments and methods, cobalt compounds, electrolytic components, etc., can solve the problems of high catalyst overpotential, growth of nanostructures, and inability to obtain multi-level nanostructured composite materials, etc. The preparation method is simple and controllable, and the effect of good catalytic activity is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

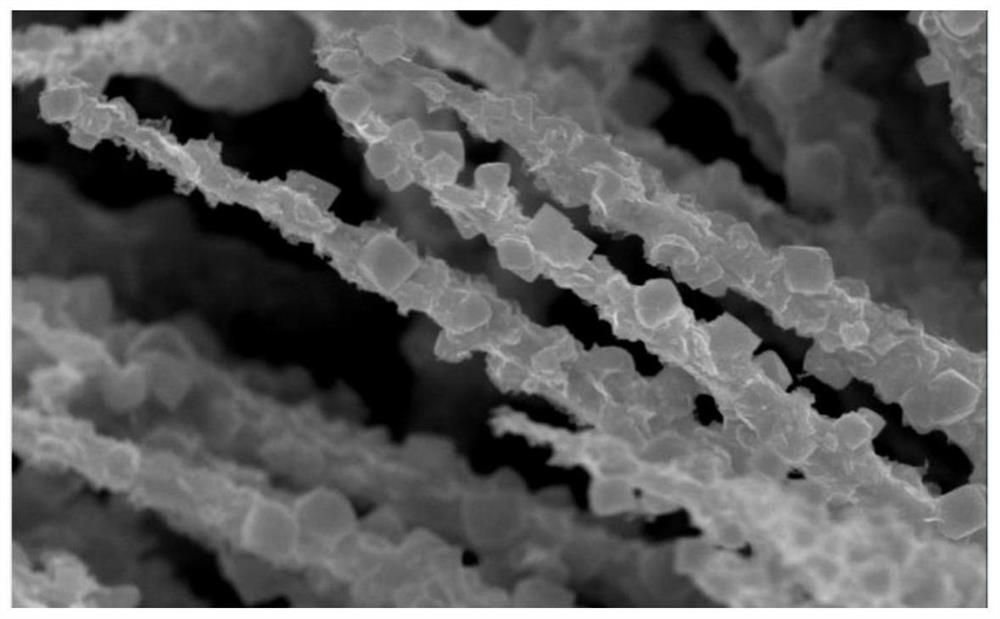

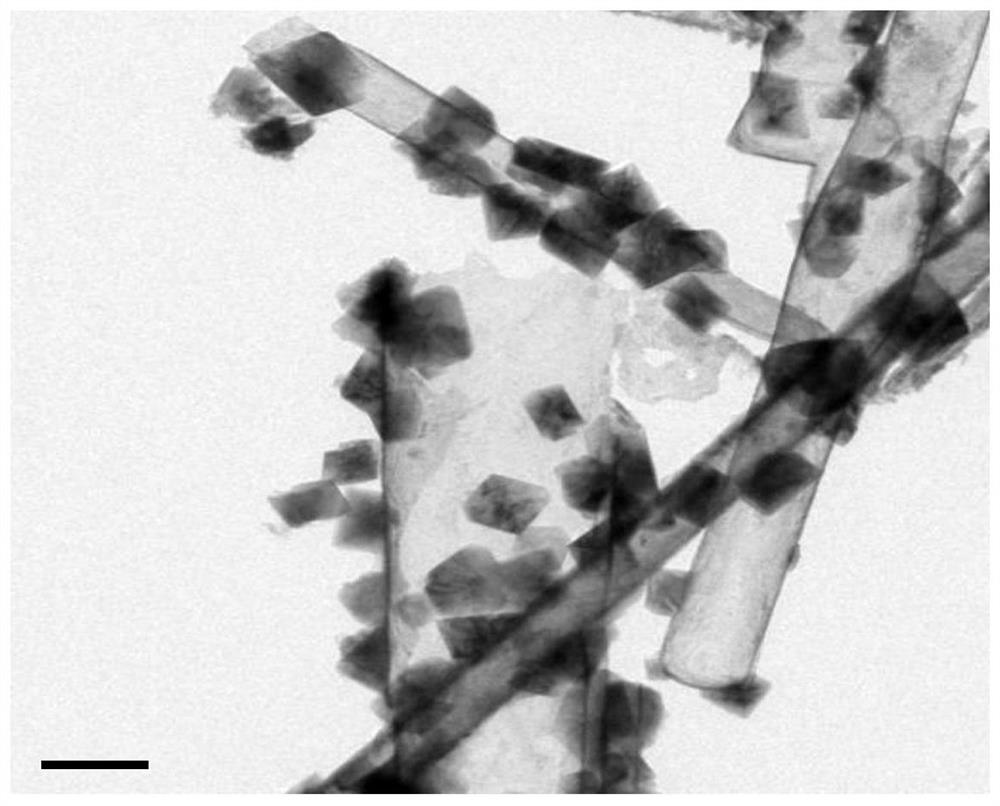

[0038] a CoS 2 The preparation method of nanotube and octahedral particle isomeric composite material comprises the following steps:

[0039] Step 1: thermally anneal a piece of carbon fiber paper with an area of 4cm×1.5cm to make it hydrophilic, and then place it in anhydrous ethanol and deionized water for ultrasonic treatment to obtain clean carbon fiber paper;

[0040] Step 2: Put 3 mmol CoCl 2 ·6H 2 O and 18mmol of urea were dissolved in 30ml of deionized water and stirred to obtain a pink solution;

[0041] Step 3: Pour the pink solution into a polytetrafluoroethylene-lined autoclave, completely immerse the clean carbon fiber paper obtained in step 1 into the pink solution, seal the autoclave, perform a hydrothermal reaction in a 120°C oven for 6 hours, wait for water Natural cooling after thermal reaction;

[0042] Step 4: Open the autoclave, take out the carbon fiber paper, wash it with deionized water, and obtain the carbon fiber paper precursor sample after dry...

Embodiment 2

[0048] The homogeneous composite material was prepared according to the steps of Example 1, except that 30 ml of precursor dispersion liquid in step 5 was adjusted to 15 ml of precursor dispersion liquid, and 15 ml of deionized water was added, and other steps remained unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com