Geopolymer water-permeable concrete brick containing biomass charcoal

A technology of permeable concrete and geopolymer, applied in ceramic products, other household appliances, household appliances, etc., can solve the problems of inability to directly use permeable concrete, inapplicability, etc., to improve urban microclimate, reduce living space, and absorb powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

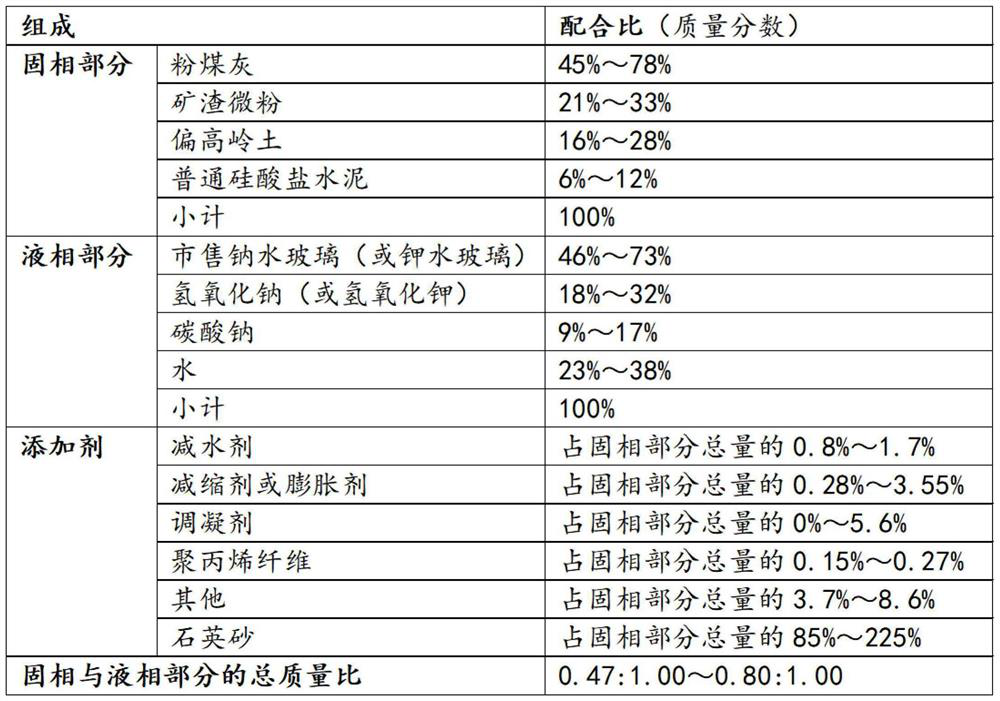

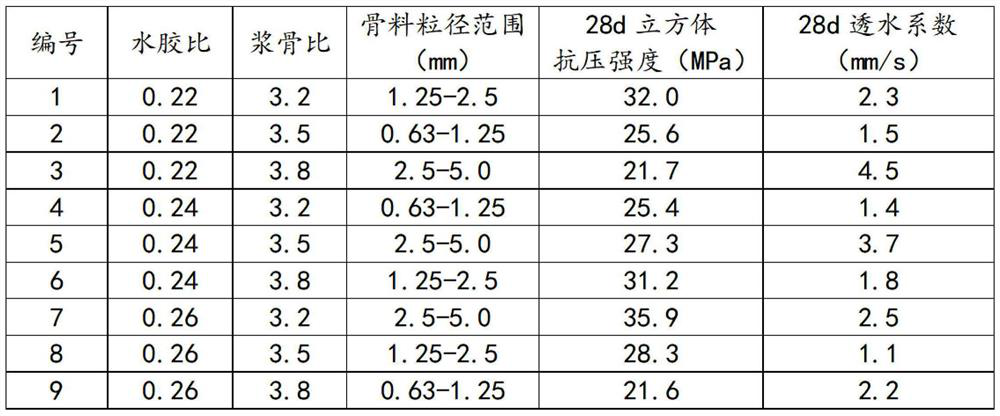

[0044] Beneficially, wherein, the selected water-binder ratio, pulp-to-bone ratio, aggregate particle size, 28d cube compressive strength and 28d water permeability coefficient are as follows: figure 2 shown.

[0045] Beneficially, in the lead material, the mass fraction of fly ash is 42%, the mass fraction of slag micropowder is 31%, the mass fraction of metakaolin is 27%, and the mass fraction of sodium water glass in the activator is 53%, The mass fraction of sodium hydroxide is 22%, the mass fraction of sodium carbonate is 13%, the mass fraction of water is 12%, the water reducing agent accounts for 1.2% of the total solid phase, and the shrinkage reducing agent accounts for 0.33% of the total solid phase. %, coagulant adjuster accounts for 3.4% of the total solid phase, polypropylene fiber accounts for 0.16% of the total solid phase, and the added biomass carbon is 0-20kg / m 3 .

[0046] Beneficially, the carbon content of the biomass carbon is 90%-95%, other trace elem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com