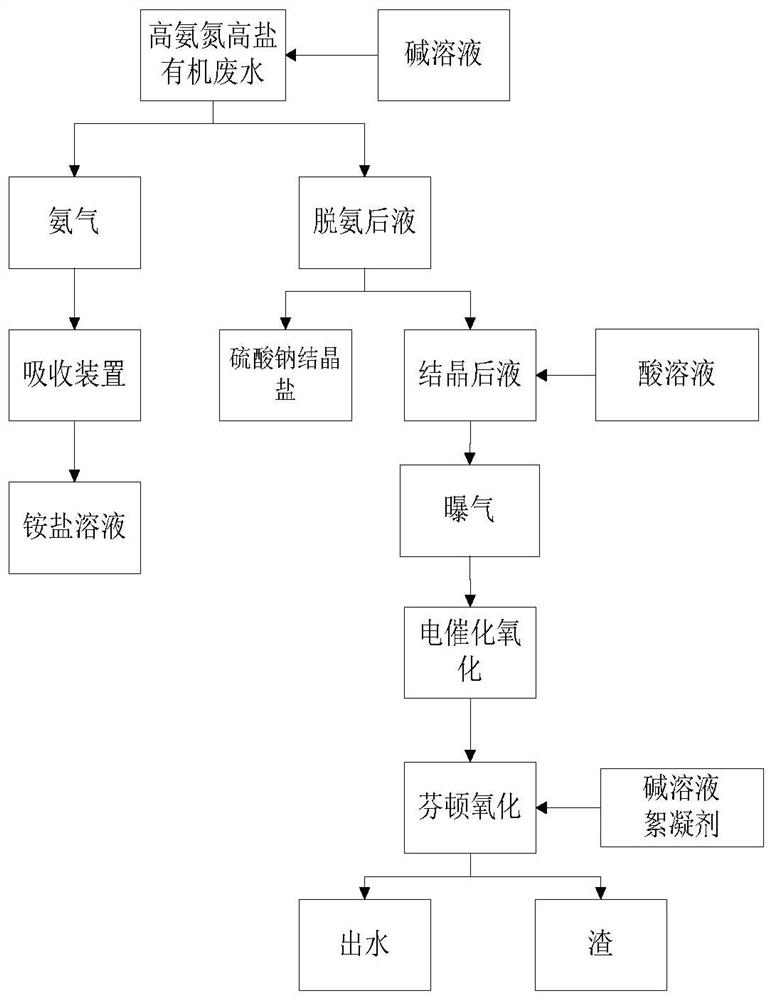

Method for removing COD (Chemical Oxygen Demand) and recycling high-ammonia-nitrogen high-salt organic wastewater

A technology of organic wastewater and high ammonia nitrogen, which is applied in chemical instruments and methods, water pollutants, process efficiency improvement and other directions, can solve the problems of reducing the COD removal efficiency of organic wastewater, polluting the air, and high treatment costs, and achieves simple and convenient treatment steps. , The effect of low processing cost and less slag production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038]First, take 1.0L of refractory organic wastewater with high ammonia nitrogen and high salt produced in the process of nickel-cobalt wet smelting. The ammonia nitrogen concentration in the wastewater is 5g / L. The main salts in the wastewater (concentration 37.59%) include ammonium sulfate, sodium sulfate, chloride Sodium, ammonium chloride, TDS of wastewater is 39.63%, organic matter includes P204, P204 ammonia soap, P204 sodium soap, sulfonated kerosene, etc. TOC concentration is 12560.75mg / L, COD concentration is 11778.9mg / L. Put the waste water into a round-bottomed flask, add a stirrer, and heat it properly. Control the temperature of the waste water to 70°C. According to the characteristics of the waste water, add an appropriate amount of NaOH with a mass fraction of 60% into the solution until no ammonia gas is produced in the solution. , using sulfuric acid with a concentration of 98% to absorb ammonia gas, and the purity of the obtained ammonium salt solution is ab...

Embodiment 2

[0040] First, take 1.0L of refractory organic wastewater with high ammonia nitrogen and high salt produced in the process of nickel-cobalt hydrometallurgy. The ammonia nitrogen concentration in the wastewater is 14.7g / L. Magnesium chloride, ammonium chloride, waste water TDS 27.93%, organics include P507, P507 ammonia soap, P507 sodium soap, sulfonated kerosene, etc. TOC concentration is 1914.27mg / L, COD concentration is 5832mg / L. Put the waste water into a round-bottomed flask, add a stirrer, and heat it properly. Control the temperature of the waste water to 70°C. According to the characteristics of the waste water, add an appropriate amount of NaOH with a mass fraction of 60% into the solution until no ammonia gas is produced in the solution. , using sulfuric acid with a concentration of 85% to absorb ammonia gas, and the purity of the obtained ammonium salt solution is about 90%. When the temperature of the waste water is lowered from 70° C. to room temperature, sodium sul...

Embodiment 3

[0042] First, take 1.0L of refractory organic wastewater with high ammonia nitrogen and high salt produced in the nickel-cobalt wet smelting process. The ammonia nitrogen concentration in the wastewater is 14.67g / L. Magnesium chloride, ammonium chloride, nickel sulfate, nickel chloride, etc., waste water TDS 19.79%, organics include P507, P507 ammonia soap, P507 sodium soap, sulfonated kerosene, etc. TOC concentration is 1277.31mg / L, COD concentration is 28732mg / L . Put the waste water into a round-bottomed flask, add a stirrer, and heat it properly. Control the temperature of the waste water to be 70 °C. According to the characteristics of the waste water, add an appropriate amount of NaOH with a mass fraction of 80% into the solution until no ammonia is produced in the solution. , using sulfuric acid with a concentration of 90% to absorb ammonia gas, and the purity of the obtained ammonium salt solution is about 80%. When the temperature of the waste water is lowered from 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cod | aaaaa | aaaaa |

| Cod removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com