High-stability high-temperature membrane electrode for fuel cell and preparation method of high-stability high-temperature membrane electrode

A fuel cell membrane and high-temperature technology, applied in fuel cells, battery electrodes, circuits, etc., can solve problems that hinder the commercialization of HT-PEMFC, affect the stability of HT-PEMFC, increase the cost of HT-PEMFC, etc., and achieve excellent output Stability, load can be precisely controlled, and the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

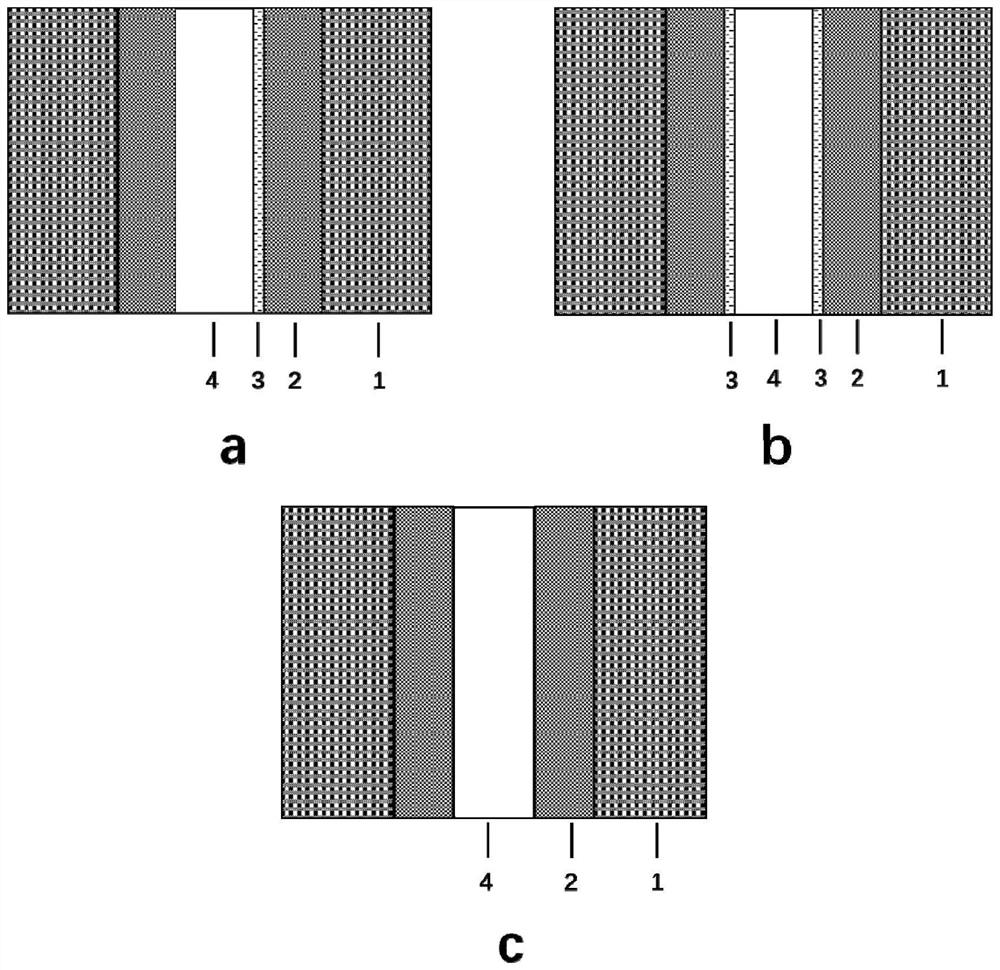

[0039] The preparation method of the present invention mainly includes three steps: the preparation of the gas diffusion electrode, the construction of the interface layer and the assembly of the membrane electrode. The schematic diagram of the membrane electrode structure is as follows: figure 1 shown, as follows:

[0040] (1) Preparation of gas diffusion electrode

[0041] First, the platinum catalyst powder and polymer solution are dispersed in water or an organic solvent (such as isopropanol, ethanol, methanol, N,N dimethylformamide, N,N dimethylacetamide, dimethyl sulfoxide ) to form a catalyst ink, usually in a mass ratio of 1:1000 to 1:50. Then put the ink in an ultrasonic vibration machine or a high-speed homogenizer for a period of time until the ink reaches a certain viscosity, usually the ink viscosity is 2-300mPa s. It is then covered on the gas diffusion layer 1 by ultrasonic spraying, blade coating or screen printing.

[0042] The prepared gas diffusion layer ...

Embodiment 1

[0050] The platinum-based catalyst is a catalyst with a platinum content of 60 wt%, the preparation method of the gas diffusion electrode is spraying, the interface layer material is graphene, and the assembly method of the membrane electrode is a gas diffusion electrode with an interface layer on both sides of the cathode and the anode. The assembly process is as follows:

[0051] (1) Disperse 60 wt% Pt / C catalyst and PTFE emulsion in ethanol (25 mL), and the mass ratio of the two is 1:400. Ultrasonic dispersion was carried out in an ultrasonic cleaner for 6 hours to obtain a uniformly dispersed suspension.

[0052] (2) adding the above-mentioned obtained uniformly dispersed suspension into the syringe, then adjusting the injection speed and ultrasonic power, and the running speed of the nozzle, and uniformly spraying the obtained ink on the gas diffusion electrode by the ultrasonic spraying equipment, at 60 ℃ of the heating table drying under low temperature to obtain an un...

Embodiment 2

[0058] The platinum-based catalyst is a catalyst with a platinum content of 60wt%. The preparation method of the gas diffusion electrode is spraying. The interface layer material is XC-72 carbon ball powder. The assembly method of the membrane electrode is that the cathode side is a gas diffusion electrode with an interface layer. The anode side is a conventional gas diffusion electrode, and its preparation process is as follows:

[0059] (1) Disperse 60 wt% Pt / C catalyst and PTFE emulsion in isopropanol (25 mL), and the mass ratio of the two is 1:500. Ultrasonic in an ultrasonic cleaner for 30 mins to obtain a uniformly dispersed suspension.

[0060] (2) the above-mentioned obtained uniformly dispersed suspension is added into the syringe, then the injection speed, ultrasonic power, and nozzle running speed are adjusted, and the obtained ink is uniformly sprayed on the gas diffusion electrode by the ultrasonic spraying equipment, and the heating table is heated at 70 ° C. dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com